Lithium-sulfur battery electrolyte containing low-polarity ether mixed lithium salt

A hybrid lithium salt and lithium sulfur battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of side reactions between lithium anode and electrolyte, rapid capacity decay, etc., and achieve excellent wettability and weak self-discharge effect. , The effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Respectively, lithium bistrifluoromethanesulfonyl imide, lithium bisfluorosulfonyl imide, tetrahydrofuran, and n-propyl ether were prepared according to the ratio of the following substances:

[0032] Experimental group 1: 4:0:8:2;

[0033] Experimental group 2: 3:1:8:2;

[0034] Experimental group 3: 2:2:8:2;

[0035] Experimental group 4: 1:3:8:2;

[0036] Experimental group 5: 0:4:8:2;

[0037] Control group: Lithium bistrifluoromethanesulfonyl imide was used as a single lithium salt, and a mixed liquid of ethylene glycol dimethyl ether and 1,3-dioxolane in a volume ratio of 1:1 was used as a solvent, and the configuration A solution with a lithium salt concentration of 1 mol / L.

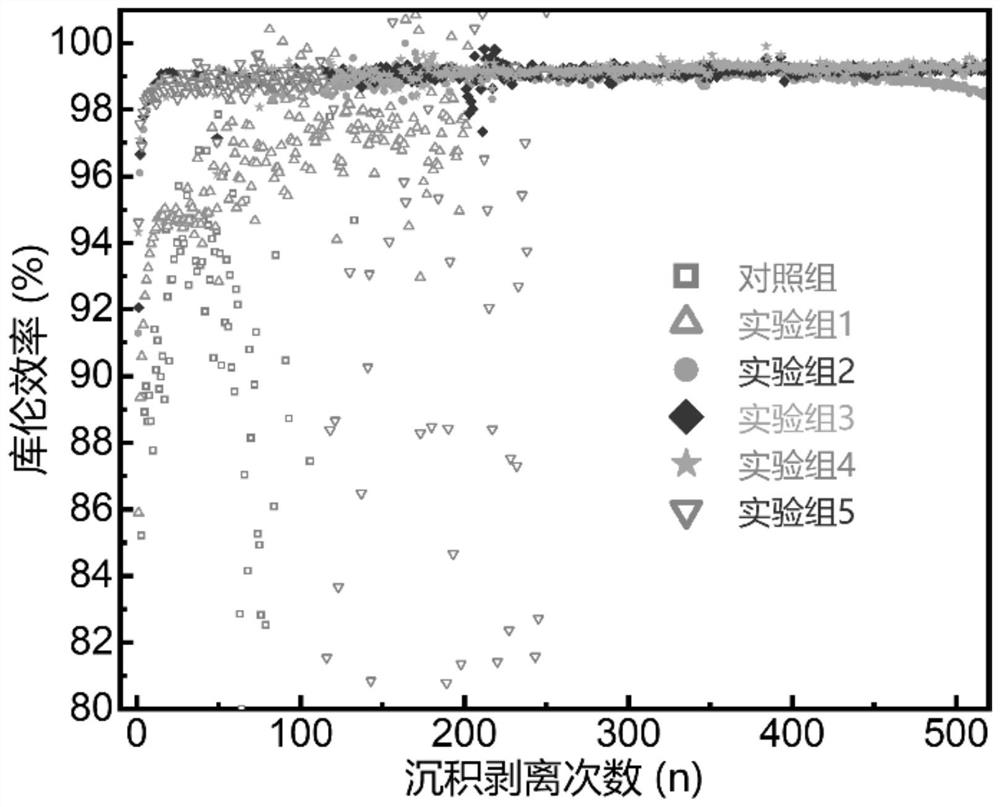

[0038] Use the above electrolyte, lithium sheets, copper sheets, and separators to assemble a lithium-copper half-cell, and at 0.5mA cm -2 current density and 1mAh cm -2 The deposition and stripping coulombic efficiency test is carried out under the areal capacity density; figure 1 A...

Embodiment 2

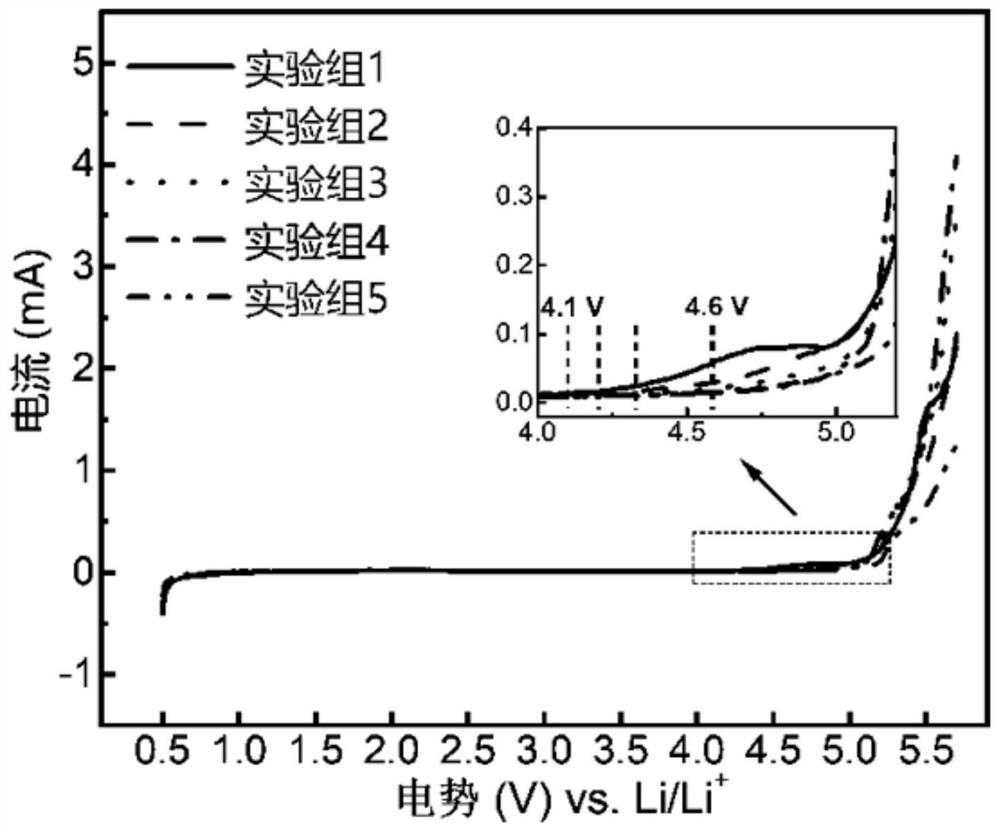

[0040] Use all the experimental group electrolytes described in Example 1 and lithium sheets, stainless steel gaskets, and separators to assemble lithium steel half cells together, and use the linear voltage sweep method to test the electrochemical window of the electrolyte by the electrochemical workstation, such as figure 2As shown, the oxidation decomposition voltages of electrolytes in all experimental groups were higher than 4V, that is, no oxidation reaction occurred within the working voltage range of lithium-sulfur batteries.

Embodiment 3

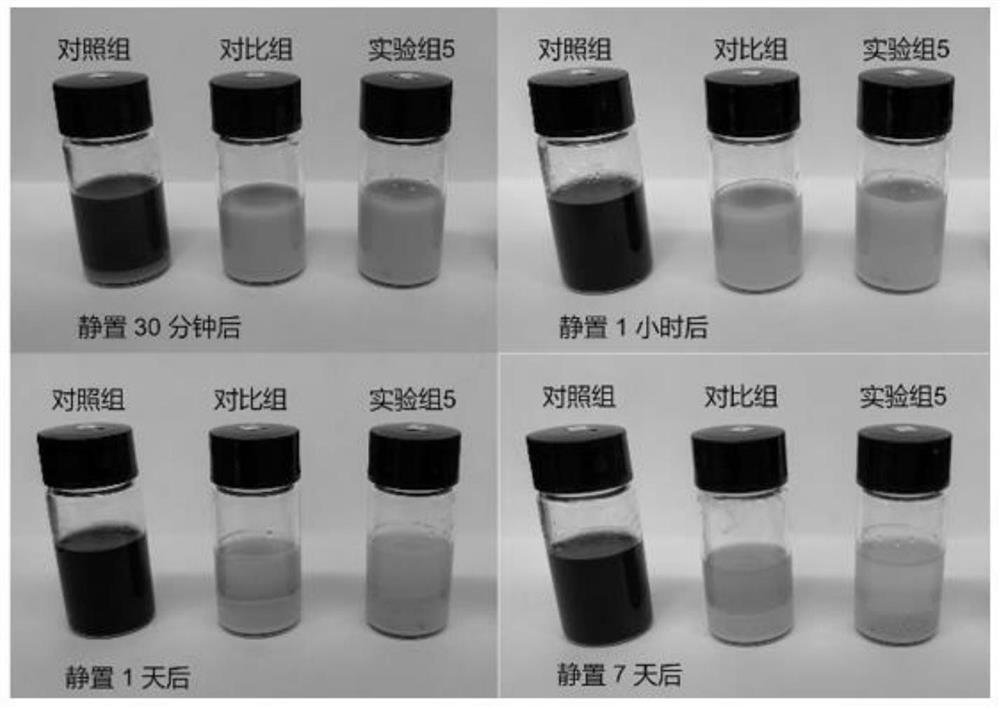

[0042] Use the control group described in embodiment 1, experimental group 5 electrolytes to Li 2 S 6 Do a solubility test. In addition, according to lithium bistrifluoromethanesulfonylimide, tetrahydrofuran is 4:10 substance ratio preparation solution (comparison group) and experiment group are compared, lithium sulfide, elemental sulfur are mixed according to specified ratio and excessively Added to the above three groups of solutions and stirred for one hour and then stood still. The lighter the color of the solution supernatant, the smaller the solubility of the solution to lithium polysulfide, indicating that the electrolyte solution proposed by the present invention represented by the experimental group 5 has significantly reduced lithium polysulfide solubility relative to the control group and the contrast group. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com