Preparation method of button type germanium air battery

An air battery and air electrode technology, which is applied to battery electrodes, fuel cell-type half-cells, primary battery-type half-cells, circuits, etc. Achieve stable long-term discharge curve, prevent battery short circuit, and prevent leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

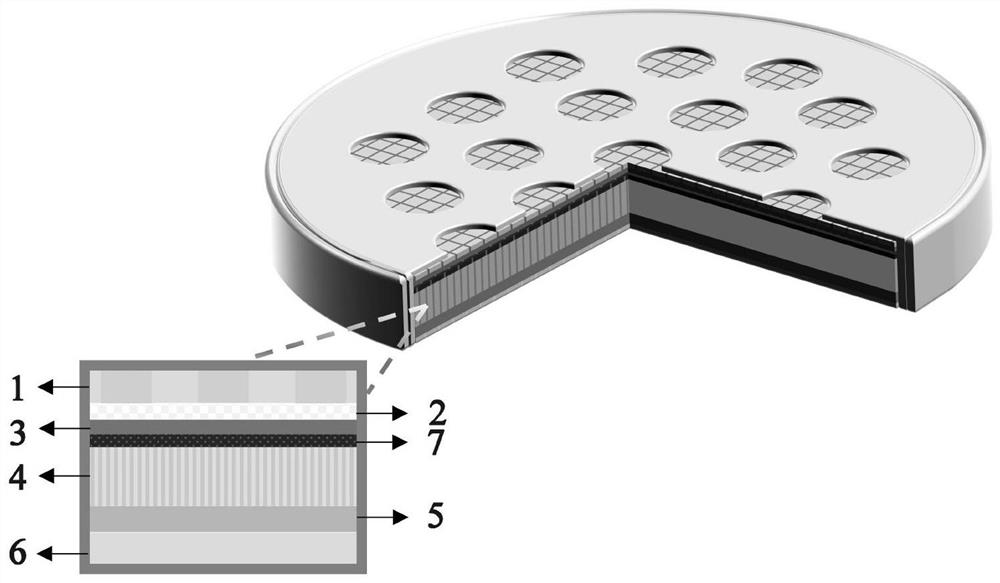

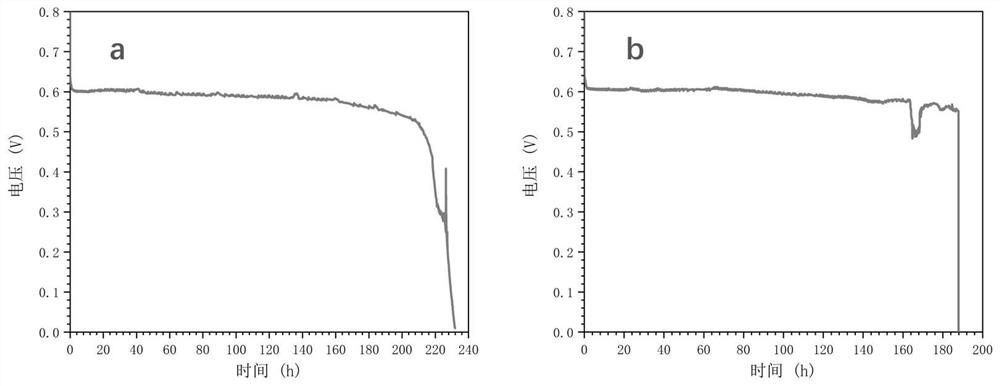

[0028] refer to Figure 1-2 , a method for preparing a button-type germanium-air battery, comprising setting a positive electrode case 1 (19 pores with a diameter of 1 mm) with several pores, an air electrode (the air electrode is sequentially integrated by a nickel mesh 2, a waterproof layer, and a carbon cloth 3 ), gel electrolyte 4, germanium sheet 5 (size: radius 0.7cm) and negative electrode shell 6, comprising the following steps:

[0029] S1. Put the germanium sheet 5, the negative electrode case 6 and the positive electrode case 1 provided with several pores into absolute ethanol for ultrasonic cleaning to remove surface impurities;

[0030] S2. Take 4.25mL of 6M KOH solution and 0.75g of CMC powder, and mix the two evenly to prepare a gel electrolyte 4 with a CMC content of 15wt%;

[0031] S3. Take 2.8 mg of Pt / C catalyst, add 700 μL Nafion solution and 300 μL isopropanol in sequence, and ultrasonically disperse the mixed solution for 30 minutes to make a catalyst co...

Embodiment 2

[0034] refer to Figure 1-2 , a method for preparing a button-type germanium-air battery, comprising setting a positive electrode case 1 (19 pores with a diameter of 1 mm) with several pores, an air electrode (the air electrode is sequentially integrated by a nickel mesh 2, a waterproof layer, and a carbon cloth 3 ), gel electrolyte 4, germanium sheet 5 (size: radius 0.7cm) and negative electrode shell 6, comprising the following steps:

[0035] S1. Put the germanium sheet 5, the negative electrode case 6 and the positive electrode case 1 provided with several pores into absolute ethanol for ultrasonic cleaning to remove surface impurities;

[0036] S2. Take 4.10 mL of 6M KOH solution and 0.90 g of CMC powder, and mix the two evenly to obtain a gel electrolyte 4 with a CMC content of 18 wt %;

[0037] S3. Take 2.8 mg of Pt / C catalyst, add 700 μL Nafion solution and 300 μL isopropanol in sequence, and ultrasonically disperse the mixed solution for 30 minutes to make a catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com