Photoacoustic sensor compatible with OCT (Optical Coherence Tomography)

A photoacoustic sensor and sensor technology, which is used in eye testing equipment, medical science, diagnosis, etc., can solve the problems of large overall system volume, low system detection sensitivity, and difficult application of human eyes, etc., and achieves high detection sensitivity, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

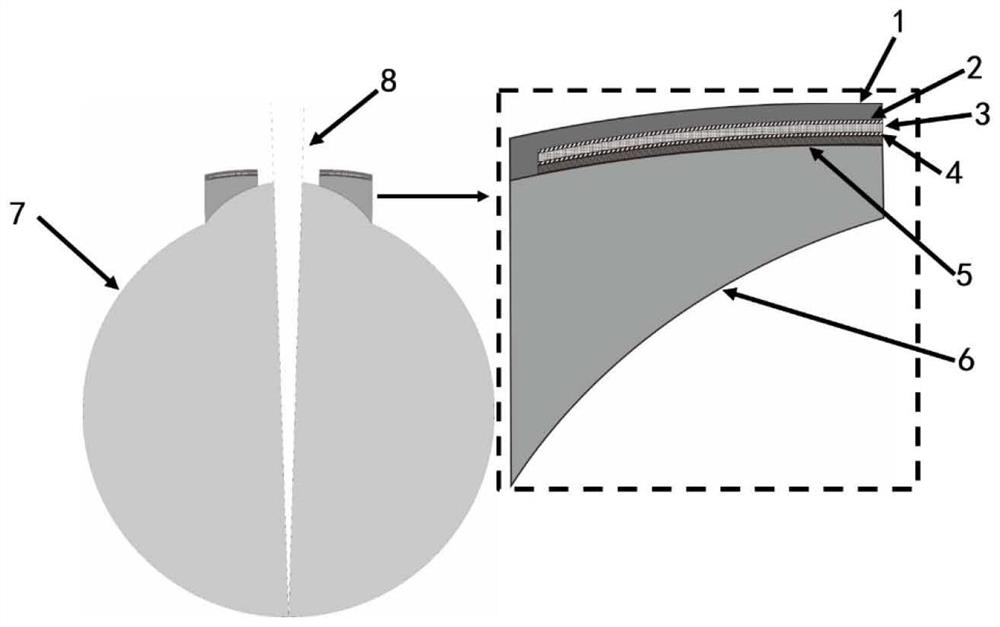

[0036] Such as figure 1 As shown, a photoacoustic sensor compatible with OCT includes: probe shell 1, upper electrode 2, curved self-focusing piezoelectric film 3, lower electrode 4, acoustic matching layer 5, eye drop coupling agent 6, eyeball 7, light Signal 8.

[0037] The probe shell 1 has a through hole at the top, the size of the through hole is 2mm, it is made of PDMS material, and is located outside the upper electrode 2, the curved self-focusing piezoelectric film 3, the lower electrode 4, and the acoustic matching layer 5; the upper electrode 2, The centers of the curved self-focusing piezoelectric film 3, the lower electrode 4, and the acoustic matching layer 5 are all provided with a 2 mm through hole; the upper electrode 2 is located between the probe shell 1 and the curved self-focusing piezoelectric film 3, and the thickness is 1 μm; the curved self-focusing The focusing piezoelectric film 3 has a thickness of 100 μm, is a curved surface with a radius of curvat...

Embodiment 2

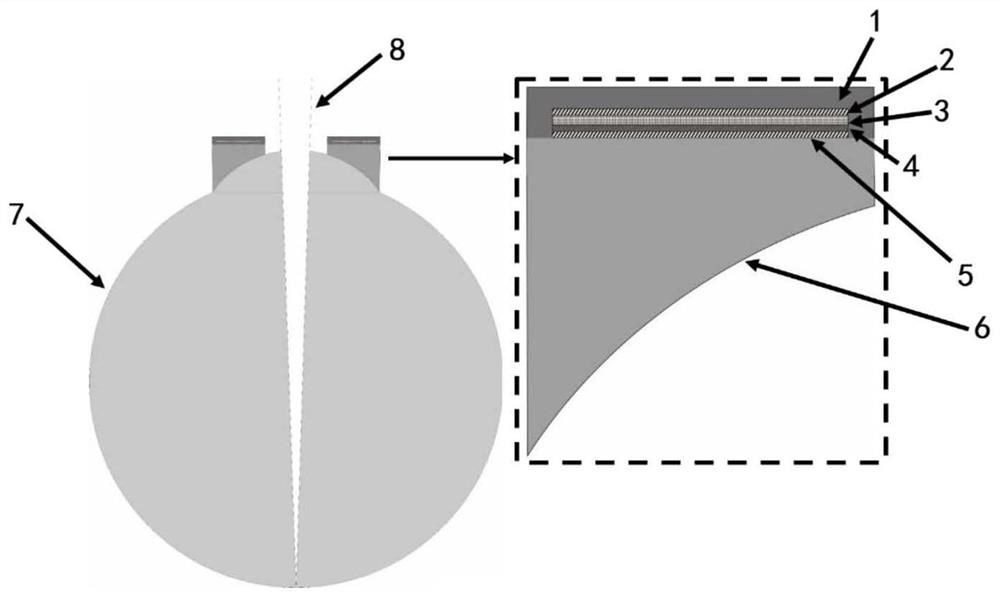

[0040] On the basis of Example 1, only the probe shell 1, upper electrode 2, curved arc piezoelectric film 3, lower electrode 4, and acoustic matching layer 5 are changed from curved arcs to flat fields to achieve the maximum transducer energy. The range detects the information on both sides of the fundus, and the rest of the structures are the same as in Embodiment 1, such as figure 2 .

[0041] The above design structure was simulated to obtain an OCT-compatible photoacoustic sensor with a central operating frequency of about 30MHz. Such as Figure 6 As shown, the OCT-compatible photoacoustic sensor can detect the largest range on both sides of the fundus center.

Embodiment 3

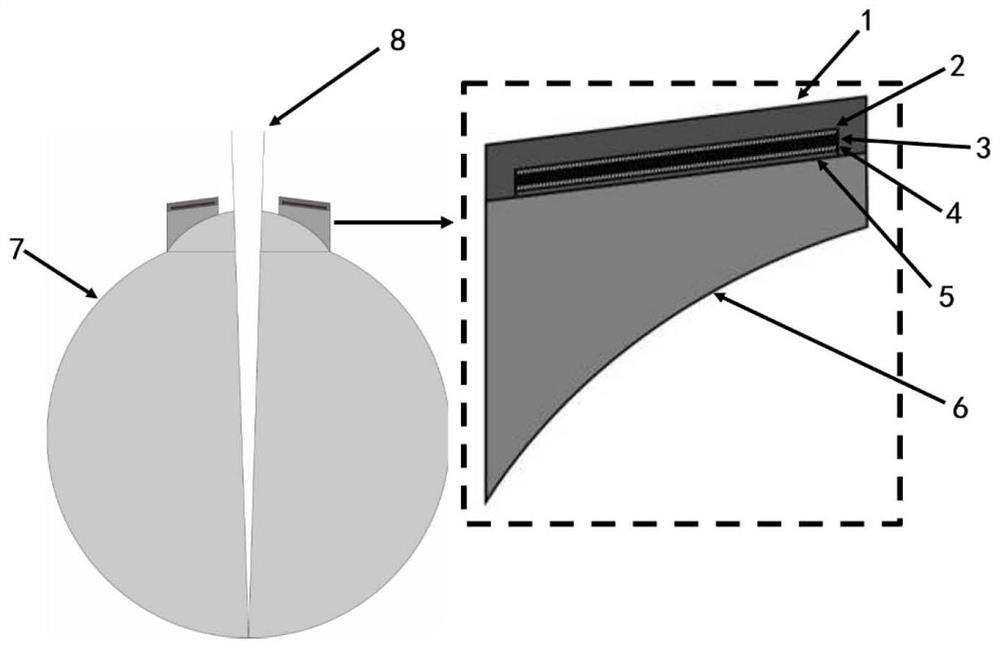

[0043] On the basis of Example 1, only the probe shell 1, the upper electrode 2, the curved arc piezoelectric film 3, the lower electrode 4, and the acoustic matching layer 5 are changed from a curved arc to an inclined flat field, and the flat field inclined piezoelectric film The inclination angle of film 3 is 5 °, and all the other structures are the same as embodiment 1, as image 3 .

[0044] The above design structure was simulated to obtain an OCT-compatible photoacoustic sensor with a central operating frequency of about 30MHz. Such as Figure 7 As shown, the OCT-compatible photoacoustic sensor can detect a large area of the fundus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com