Homologous and heterogeneous interface structure composite material and preparation method thereof

A composite material and heterogeneous interface technology, applied in the field of electrochemical catalysis, can solve the problems of not fully reflecting the essential characteristics of the homologous heterogeneous interface, and the interface structure and internal materials cannot be well exposed, so as to achieve excellent electrocatalytic activity and its stability, significant interfacial effects, rapid heating and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In a specific embodiment, a method for preparing a homologous heterogeneous interface composite material is also provided, comprising the following steps:

[0056] A. Preparation of metal salt and thiourea precursor loaded on carbon fiber substrate: Soak carbon fiber substrate in a mixed aqueous solution of metal salt and thiourea to obtain metal salt and thiourea loaded carbon fiber;

[0057] B. Preparation of homologous heterogeneous interface composite material: connect the metal salt and thiourea-loaded carbon fiber to an external circuit, and instantaneously energize to obtain the homologous heterogeneous interface composite material.

[0058] In the present invention, the carbon fiber is soaked in the mixed solution of metal salt and thiourea first, and then through instantaneous energization, in this process, the metal / alloy sulfide is first generated on the surface of the carbon fiber, and the sulfide is reduced to metal / alloy due to carbothermal reduction. Allo...

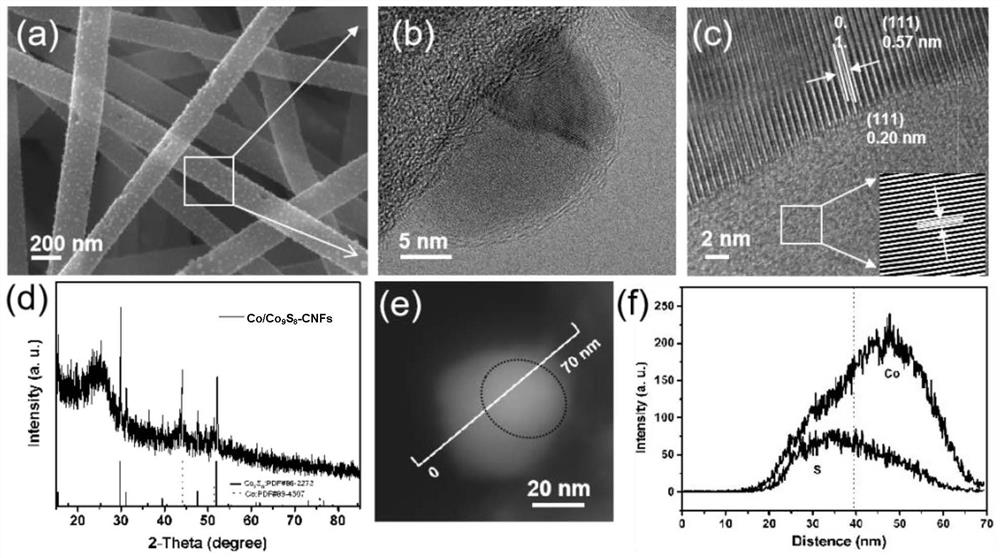

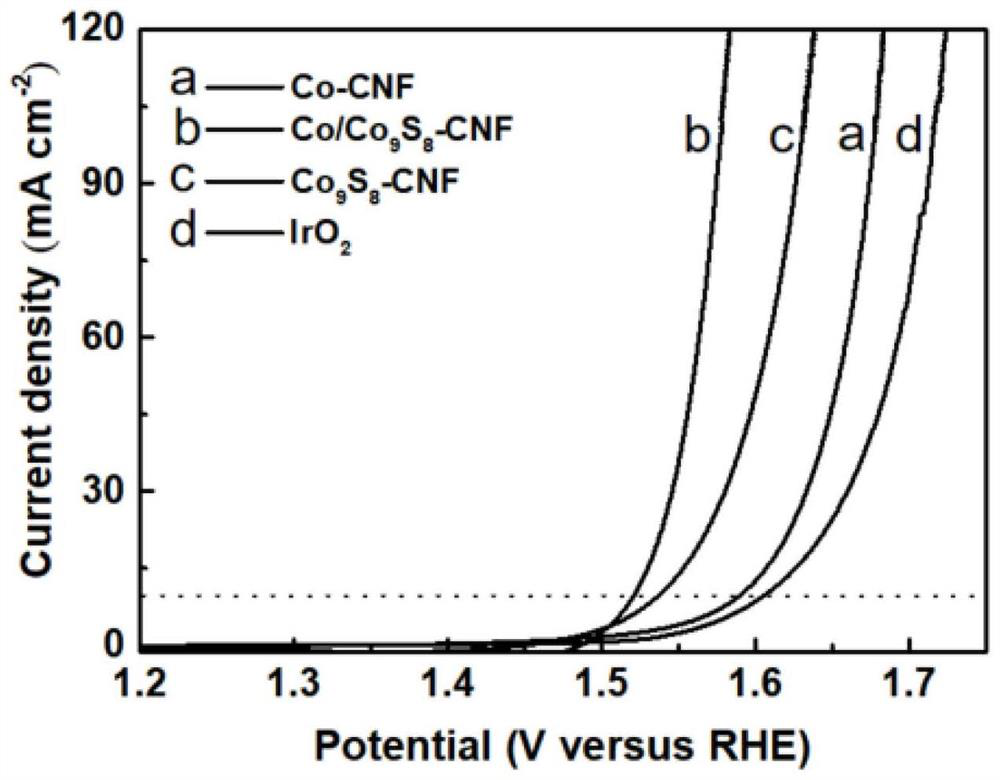

Embodiment 1

[0080] This embodiment provides a homologous heterogeneous interface Co / Co 9 S 8 A method for preparing a carbon nanofiber composite material, comprising the following steps:

[0081] (1) Preparation of electrospinning solution: dissolve polyacrylonitrile (PAN) in N,N-dimethylformamide (DMF), stir to obtain a homogeneous solution, and polyacrylonitrile (PAN) and N,N- The mass ratio of dimethylformamide (DMF) is 1:9;

[0082] (2) Transfer the homogeneous solution into a syringe and perform electrospinning with an electrospinning machine. The working parameters of electrospinning are: working voltage 25kV, distance between needle tip and collector 15cm, solution flow rate 1mL h -1 , to obtain white felt-like electrospun nanofibers;

[0083] (3) Place the electrospun nanofibers in a tube furnace and heat at 1°C min from room temperature -1 Heating to 270°C at a rate of 2h for pre-oxidation, then, in an inert atmosphere at 5°C min -1 The temperature was raised to 1000°C at a ...

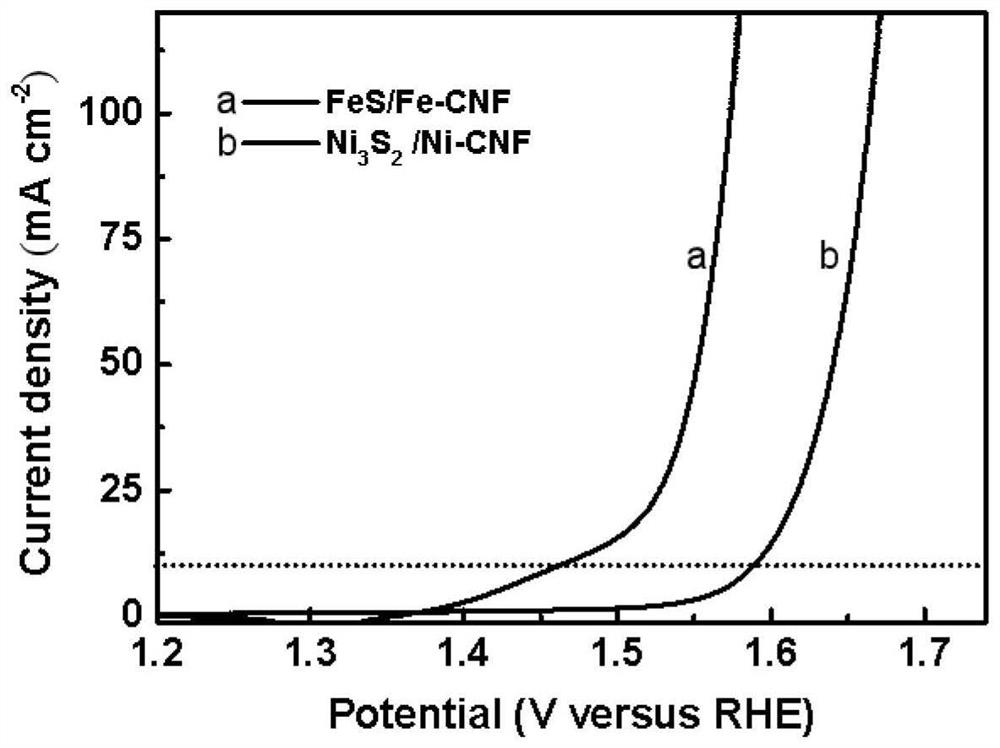

Embodiment 2

[0093] This embodiment provides a homologous heterogeneous interface Ni / Ni 3 S 2 A method for preparing a carbon nanofiber composite material, comprising the following steps:

[0094] (1) Preparation of electrospinning solution: dissolve polyacrylonitrile (PAN) in N,N-dimethylformamide (DMF), stir to obtain a homogeneous solution, and polyacrylonitrile (PAN) and N,N- The mass ratio of dimethylformamide (DMF) is 1:9;

[0095] (2) Transfer the homogeneous solution into a syringe and perform electrospinning with an electrospinning machine. The working parameters of electrospinning are: working voltage 25kV, distance between needle tip and collector 15cm, solution flow rate 1mL h -1 , to obtain white felt-like electrospun nanofibers;

[0096] (3) Place the electrospun nanofibers in a tube furnace and heat at 1°C min from room temperature -1 Heating to 270°C at a rate of 2h for pre-oxidation, then, in an inert atmosphere at 5°C min -1 The temperature was raised to 1000°C at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com