Method for preparing amorphous oxyhydroxide catalyst by mechanical stirring method and research on high-efficiency hydrogen production by electrolyzing water by using amorphous oxyhydroxide catalyst

A mechanical stirring and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, electrolysis components, etc., to achieve the effects of low energy consumption, high specific surface area, and improved oxygen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

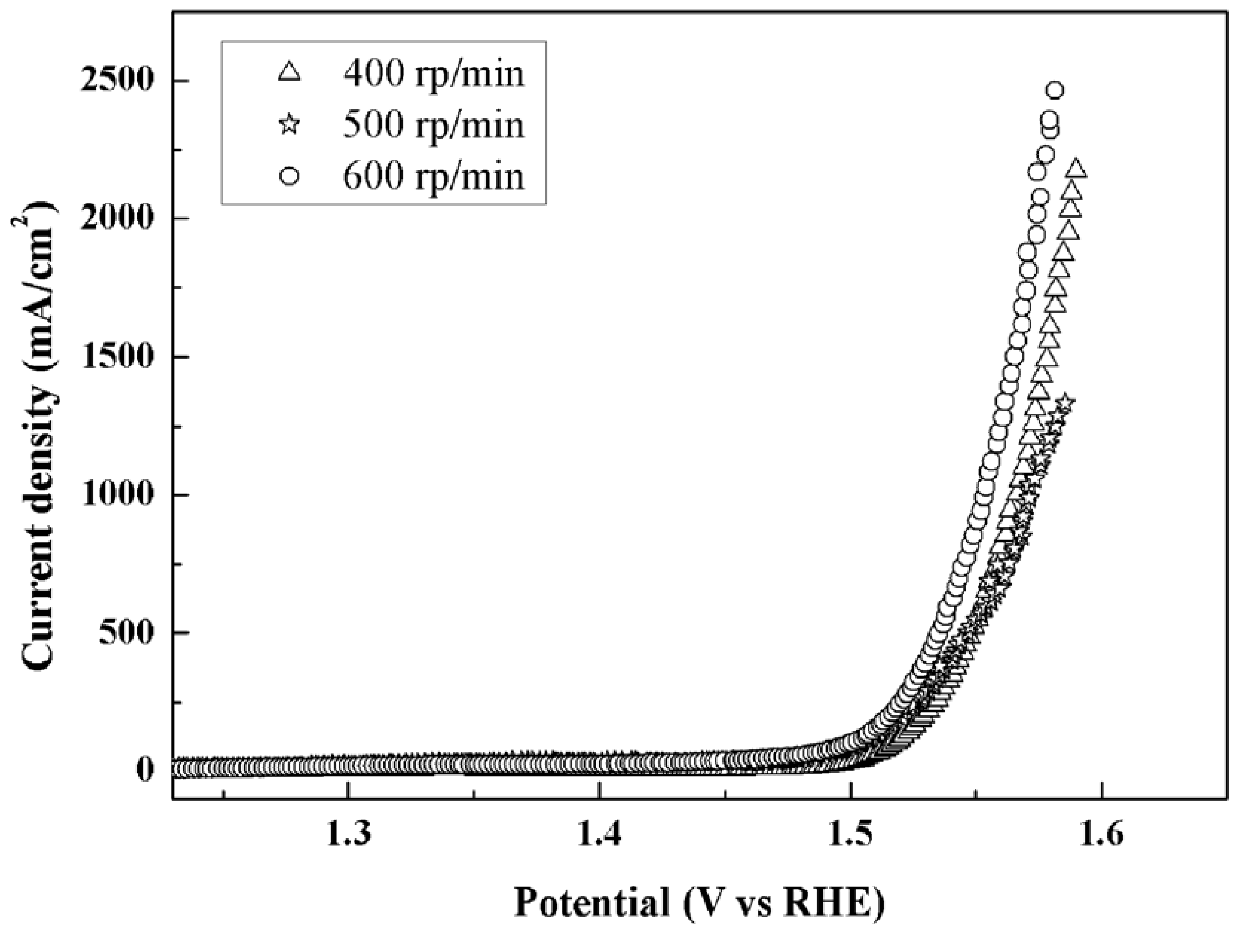

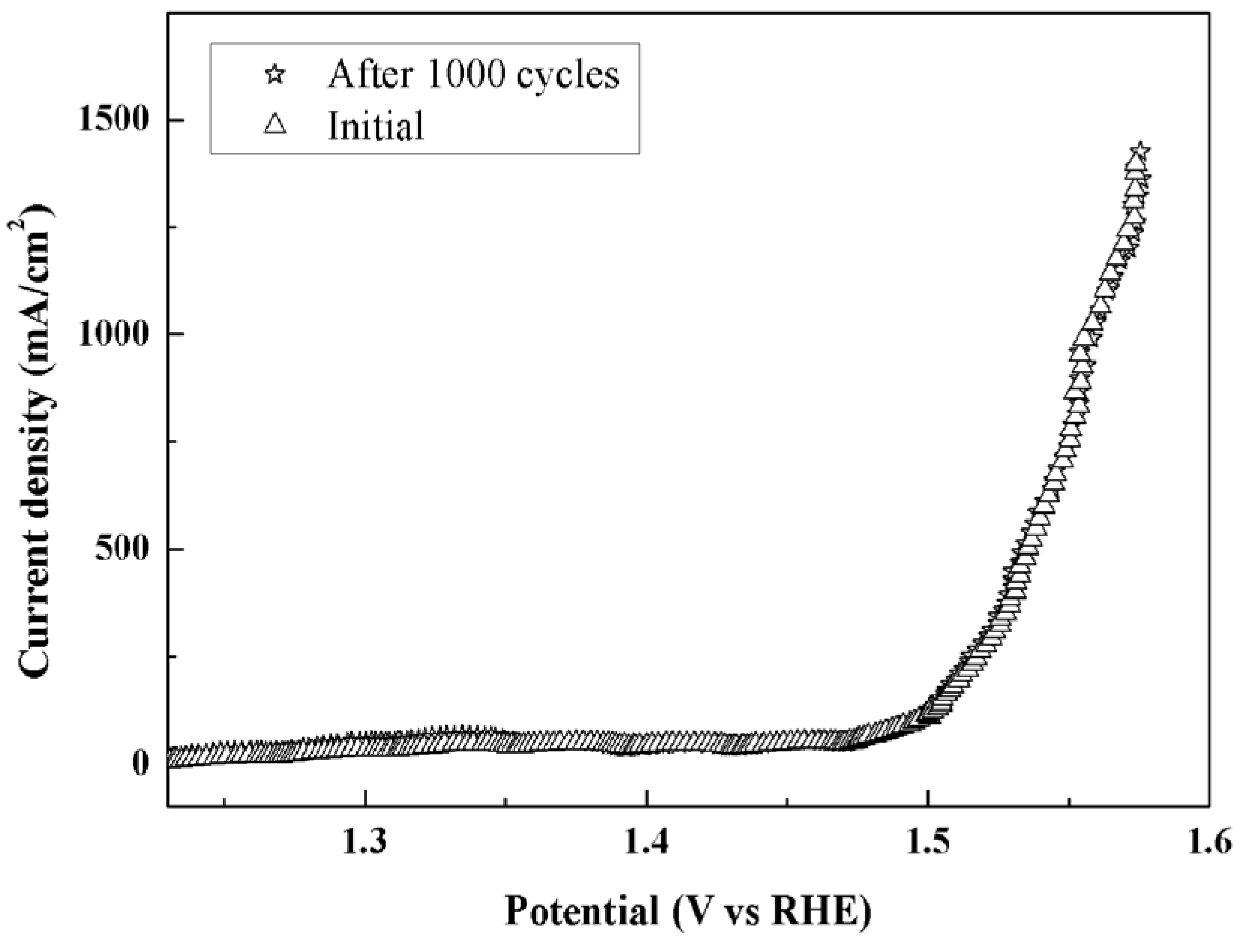

[0025] Embodiment 1 Amorphous cobalt-iron-based oxyhydroxide Co 1-x Fe x The preparation of OOH catalyst and its electrocatalytic oxygen evolution performance in 1 M KOH environment are as follows:

[0026] Step 1: Cut the cobalt foam base, the cutting area is 12 mm long * 5 mm wide.

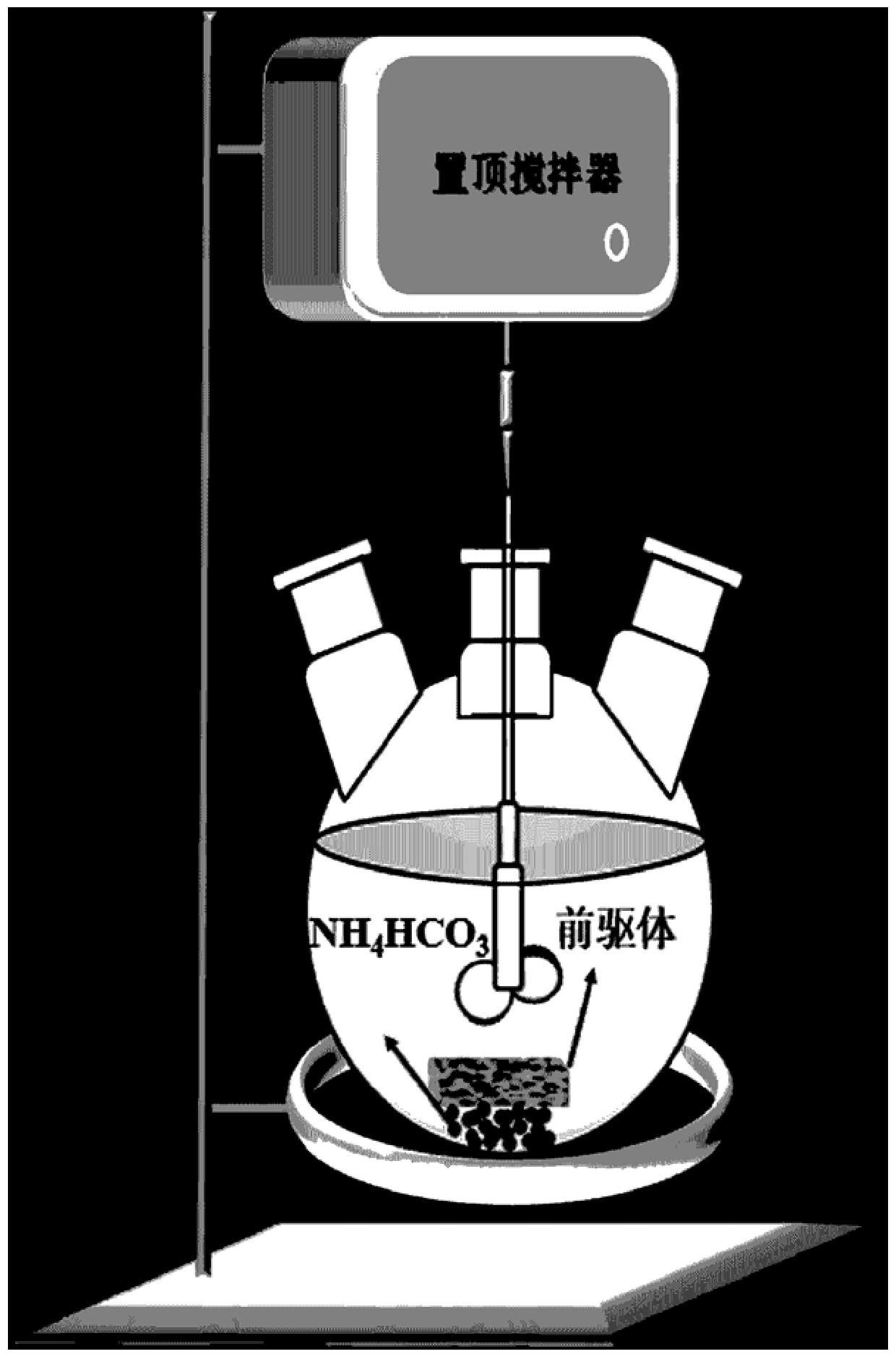

[0027] Step 2: Prepare an amorphous oxide mixture mesoporous film, the method is as follows: 0.3 g FeCl 3 ·6H 2 O was fully dissolved in a round-bottomed flask containing 50 ml of ethanol, and ultrasonically mixed at room temperature for about 10 minutes, and then 0.2 g of NH 4 HCO 3 Added to the alcohol solution, the FeCl 3 Alcoholic solution-treated cobalt foam is immersed in the precursor solution.

[0028] Step 3: Place the round bottom flask in the overhead stirrer, adjust the relevant rotation number and stirring time. After stirring, the sample was taken out and soaked in deionized water for 15 minutes to remove the solution adsorbed on the surface. Then, the samples were left to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com