Synthesis method of key intermediate of diatrizoic acid

A synthetic method and intermediate technology, applied in the field of drug synthesis, can solve the problems of increasing risk and increasing production cost, and achieve the effect of controlling production cost and reaction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

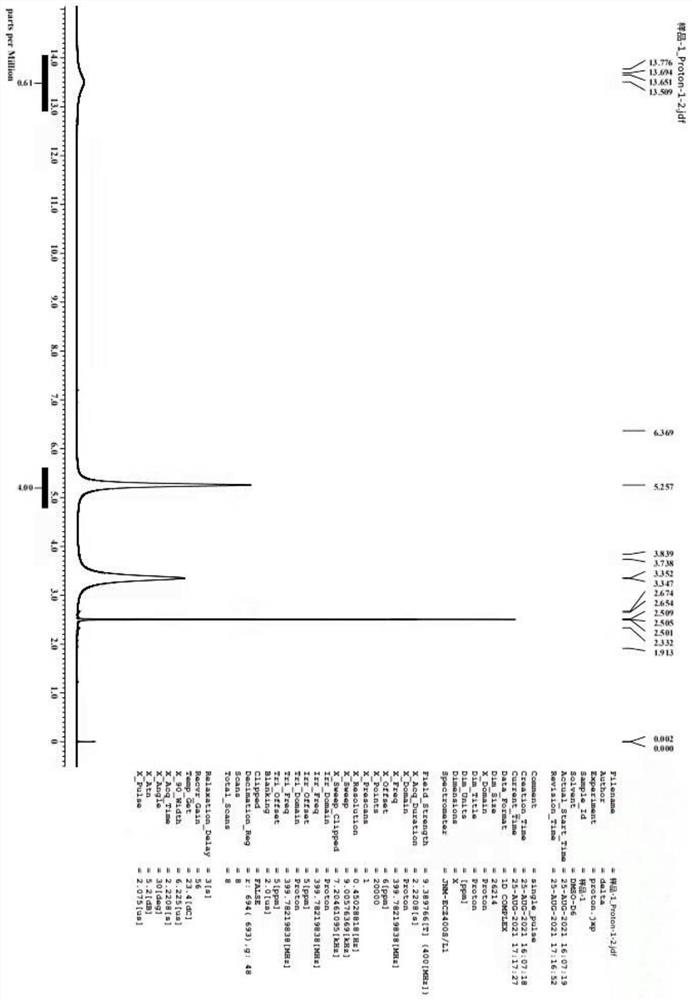

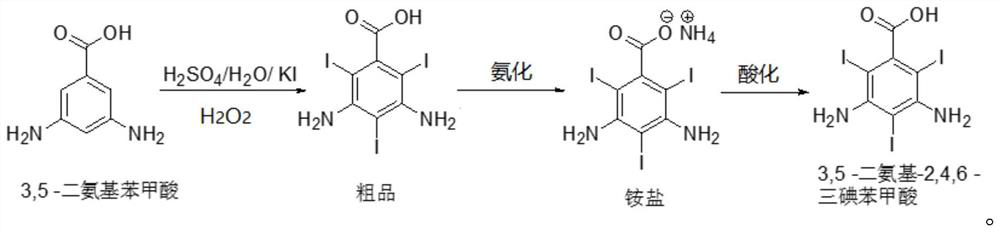

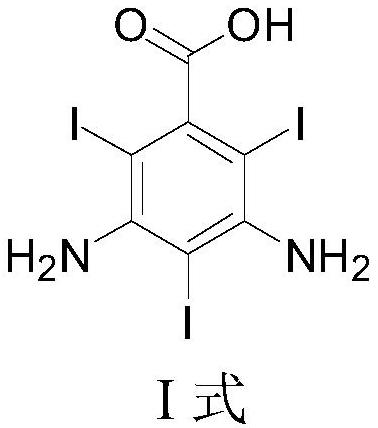

[0032] This exemplary embodiment provides a synthetic method of a key intermediate of diatrizoic acid, which is 3,5-diamino-2,4,6-triiodobenzoic acid, characterized in that the synthetic method comprises the following steps:

[0033] (1) Using 3,5-diaminobenzoic acid, sulfuric acid, potassium iodide and hydrogen peroxide as reactants, reacting in a solvent environment to obtain crude 3,5-diamino-2,4,6-triiodobenzoic acid;

[0034] (2) Ammonia the crude product of 3,5-diamino-2,4,6-triiodobenzoic acid to obtain ammonium salt;

[0035] (3) Acidifying the ammonium salt to obtain the intermediate 3,5-diamino-2,4,6-triiodobenzoic acid.

[0036] Its reaction formula is as follows:

[0037]

[0038] The synthesis method of the key intermediate of diatrizoic acid in the embodiment of the present disclosure provides a new method for synthesizing the key intermediate of diatrizoic acid, which can effectively control the production cost and avoid the use of environmentally unfriendly...

Embodiment 1

[0041] Add 3,5-diaminobenzoic acid (50.0g) and purified water (2100ml) into a 5L jacketed bottle (R1), add sulfuric acid (50.0g) dropwise to the above system, add KI (180.0g) Add to R1, control the temperature at 30°C, add 30% H 2 o 2 (119.2g) was added dropwise to R1, after the dropwise addition was completed, the reaction temperature was adjusted to 55°C, and the reaction was carried out at this temperature for 3h. After the reaction is completed, adjust the temperature of the system to 20-25 ° C, and drop 10% sulfurous acid aqueous solution into the system until it is non-oxidizing (KI-I 2 test paper), stirred for 30min. Filter, transfer the crude product to a 2L jacketed bottle (R2), add saturated ammonium chloride aqueous solution (850g) to R2, adjust the pH to 9 with concentrated ammonia water, adjust the system temperature to 20°C, and stir at this temperature 3h, filtered to obtain light brown ammonium salt. Transfer the above ammonium salt to a 2L jacketed bottle ...

Embodiment 2

[0045] Add 3,5-diaminobenzoic acid (50.0g) and purified water (2000ml) into a 5L jacketed bottle (R1), add sulfuric acid (49.5g) dropwise to the above system, add KI (169.1g) Add to R1, control the temperature at 20°C, add 30% H 2 o 2 (115.5g) was added dropwise to R1, after the dropwise addition, the reaction temperature was adjusted to 50°C and reacted at this temperature for 1h. After the reaction is completed, adjust the temperature of the system to 20-25 ° C, and drop 10% sulfurous acid aqueous solution into the system until it is non-oxidizing (KI-I 2test paper), stirred for 30min, filtered, transferred the crude product to a 2L jacketed bottle (R2), added saturated aqueous ammonium chloride solution (750g) to R2, adjusted the pH to 8 with concentrated ammonia water, and adjusted the system temperature to 20°C , Stir at this temperature for 3h, filter the light brown ammonium salt. Transfer the above ammonium salt to a 2L jacketed bottle (R3), add purified water (900m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com