Preparation method of bismuth ferrite film

A technology of bismuth ferrite and thin films, which is applied in chemical instruments and methods, iron compounds, final product manufacturing, etc., can solve the problems that cannot meet the needs of ultra-thin bismuth ferrite thin films, and achieve easy large-area preparation, high yield rate, The effect of strong base universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

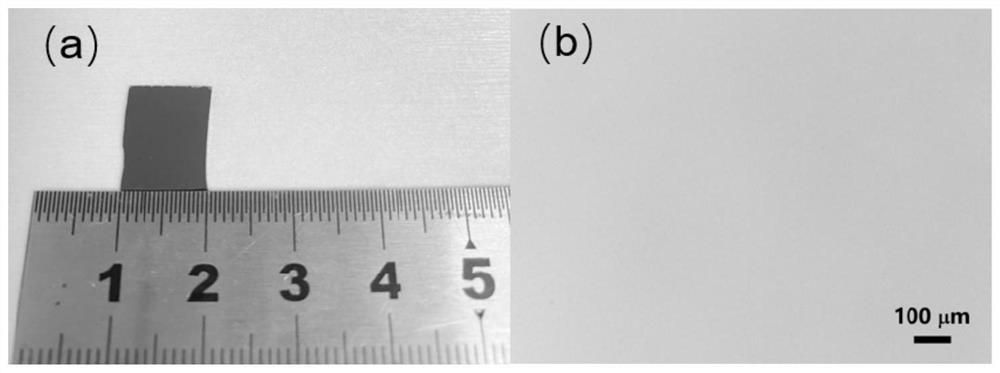

Embodiment 1

[0030] A kind of preparation method of bismuth ferrite film of the present invention, comprises the steps:

[0031] Step 1, substrate cleaning

[0032] Silicon wafers are selected as the substrate, and the substrate is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 5-10 minutes before use, and finally dried quickly with nitrogen.

[0033] Step 2, preparation of precursor solution

[0034] (1) Mixing an appropriate amount of Fe(NO 3 ) 3 9H 2 O and Bi(NO 3 ) 3 ·5H 2 O (the molar ratio is 1:1.02-1.06), dissolved in ethylene glycol methyl ether, stirred at a temperature of about 15°C until the solution is clear, and the obtained solution is a transparent reddish-brown solution 1;

[0035] (2) Add a small amount of solvent to dilute the solution to obtain a certain concentration (0.5mol / L) of the precursor solution 2, and the solvent for dilution is preferably ethylene glycol methyl ether;

[0036] (3) Place the precursor solution obtained in ...

Embodiment 2

[0044] The preparation method of the bismuth ferrite thin film of this embodiment is different from that of the first embodiment in that no deionized rinse is performed before the annealing, and the thickness of the obtained thin film is about 264 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com