Preparation process and device of selenized chitosan oligosaccharide and application of selenized chitosan oligosaccharide

A kind of chitosan oligosaccharide and preparation technology, which can be used in medical preparations containing active ingredients, mixers with rotating stirring devices, chemical/physical/physicochemical processes using energy, etc., and can solve the problem of product yield decline , unfavorable reactions, full of workshops and other problems, to achieve the effect of preventing the temperature from rising too high, fully dialysis concentration, and good cell repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

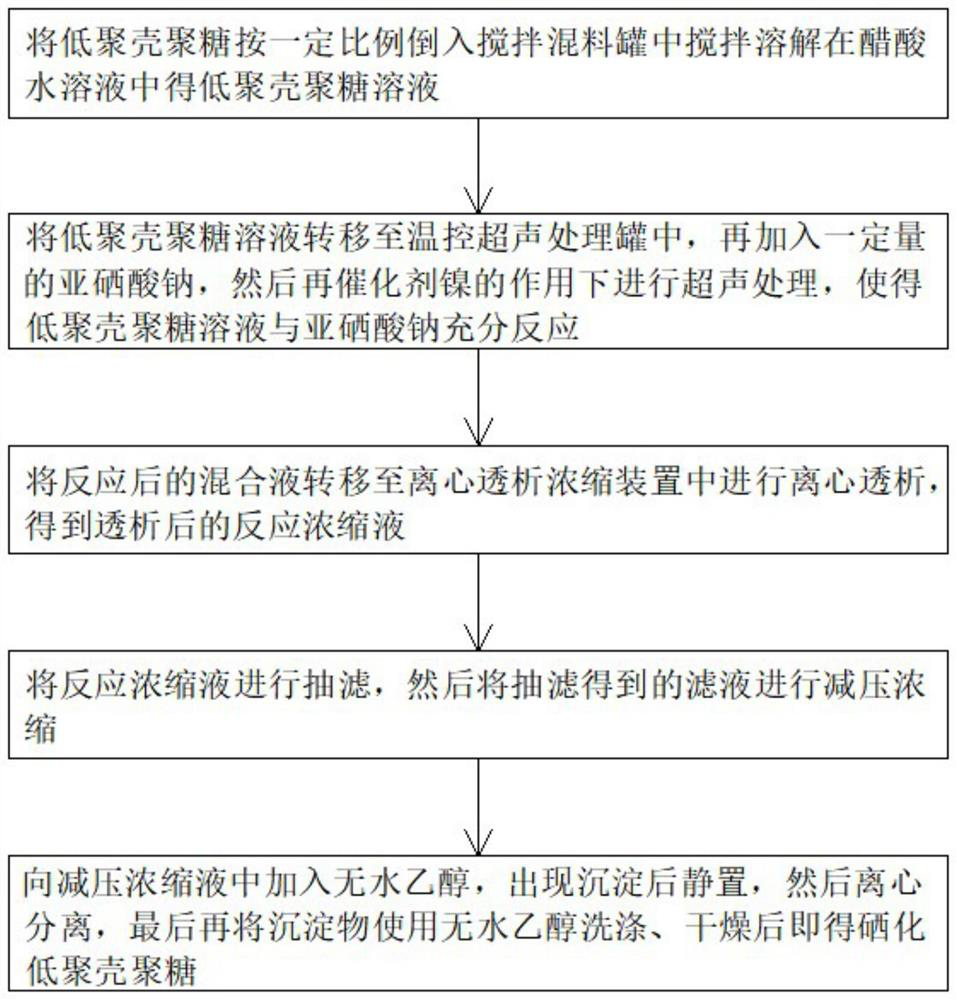

[0049] Embodiment 1 discloses a kind of preparation technology of selenized chitosan oligosaccharide, comprising the steps:

[0050] 1) Put the chitosan oligosaccharide into the stirring mixing tank according to a certain proportion and stir and dissolve it in the aqueous acetic acid solution to obtain the chitosan oligosaccharide solution; wherein the mass ratio of the chitosan oligosaccharide and the aqueous acetic acid solution is 2:15, and the acetic acid The pH of the aqueous solution is 4.

[0051] 2) transfer the chitosan oligosaccharide solution to a temperature-controlled ultrasonic treatment tank, then add a certain amount of sodium selenite, and then carry out ultrasonic treatment under the action of catalyst nickel, so that the chitosan oligosaccharide solution and selenous acid Sodium fully reacted; the mass ratio of sodium selenite to chitosan oligosaccharide solution was 3:16, ultrasonic treatment was performed for 35 minutes, and the temperature during ultrason...

Embodiment 2

[0056] Embodiment 2 discloses a kind of preparation technology of selenized chitosan oligosaccharide, comprising the steps:

[0057] 1) Put the chitosan oligosaccharide into the stirring mixing tank according to a certain proportion and stir and dissolve it in the aqueous acetic acid solution to obtain the chitosan oligosaccharide solution; wherein the mass ratio of the chitosan oligosaccharide and the aqueous acetic acid solution is 1:7, and the acetic acid The pH of the aqueous solution is 3.8.

[0058] 2) transfer the chitosan oligosaccharide solution to a temperature-controlled ultrasonic treatment tank, then add a certain amount of sodium selenite, and then carry out ultrasonic treatment under the action of catalyst nickel, so that the chitosan oligosaccharide solution and selenous acid The sodium fully reacted; the mass ratio of sodium selenite to chitosan oligosaccharide solution was 1:5, ultrasonic treatment was performed for 40 minutes, and the temperature during ultr...

Embodiment 3

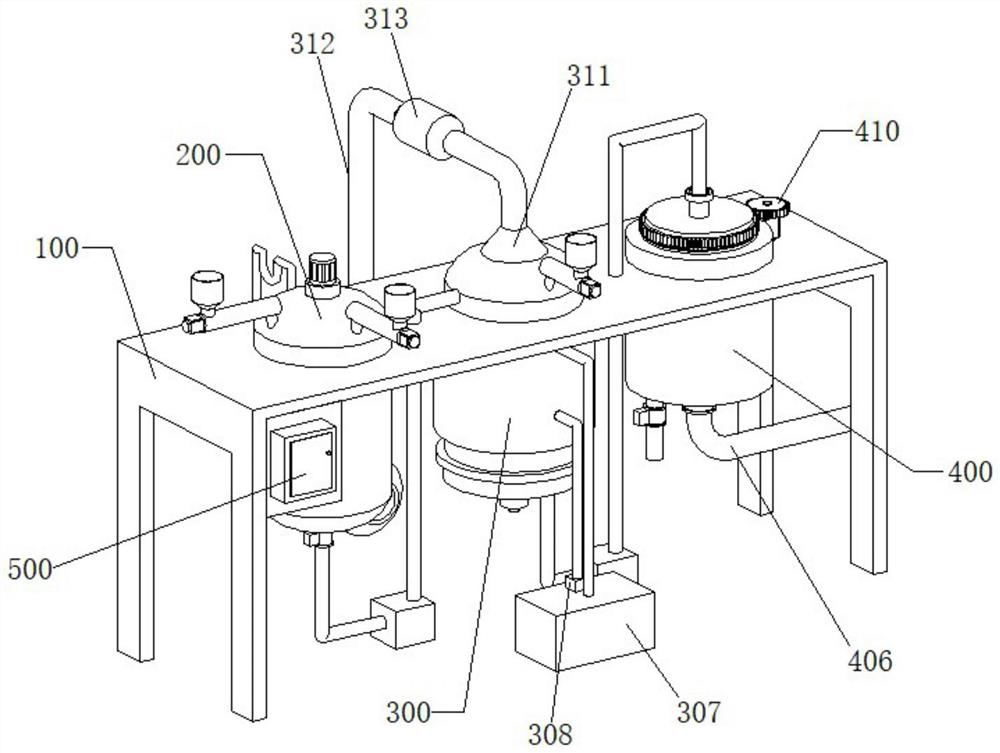

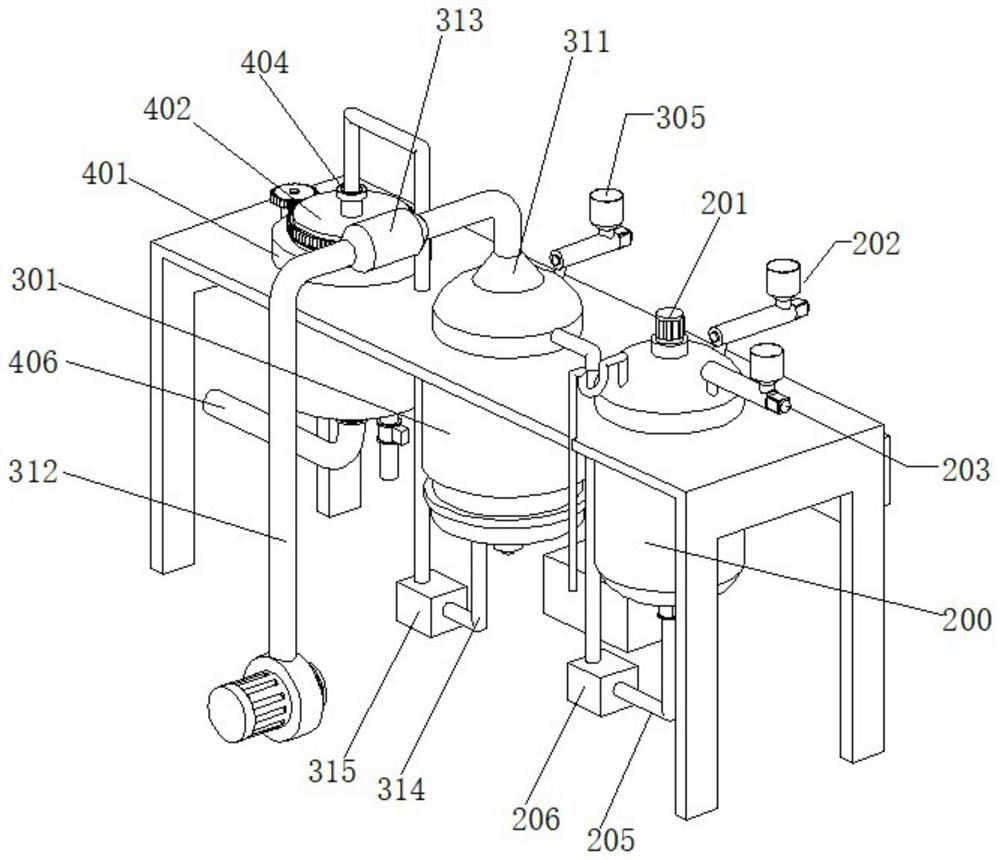

[0064] This embodiment 3 discloses a device used in the preparation process of selenized chitosan oligosaccharides in embodiment 1 and embodiment 2, with reference to the attached figure 2 And attached image 3 , the main part of the device includes a frame 100, a stirring and mixing tank 200, a temperature-controlled ultrasonic treatment tank 300, a centrifugal dialysis concentration device 400 and a control box 500, a stirring and mixing tank 200, a temperature-controlled ultrasonic treatment tank 300, a centrifugal dialysis concentration The device 400 is fixedly arranged on the upper end of the frame 100 in sequence from left to right.

[0065] Reference attached Figure 4 , the upper end of stirring mixing tank 200 is provided with stirring driving device 201, and the output shaft lower end of stirring driving device 201 is connected with the stirring frame (not shown in the figure) that is arranged on stirring mixing tank 200 inner cavity, and stirring mixing tank The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com