Positive photosensitive polyimide resin, resin composition and preparation method and application thereof

A polyimide resin, positive photosensitive technology, used in optomechanical equipment, photosensitive materials for optomechanical equipment, optics, etc., can solve the problem of low adhesion of positive photosensitive polyimide resin, difficult IC The actual use requirements of the chip, etc., to achieve the effects of low dielectric constant, high graphic resolution, steepness, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Embodiment 1, preparation hydroxyl-containing polyimide resin, composition and polyimide film

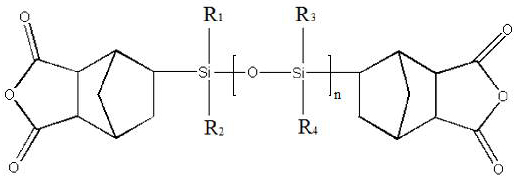

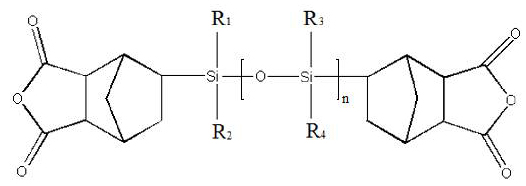

[0099] In a 500ml three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 220g N-methylpyrrolidone (NMP) and 21.50g 1,3 diamino-4,6 dihydroxybenzene in sequence, and stir at room temperature Dissolved to form a homogeneous hydroxyl-containing diamine solution. Then, weigh 18.56g of TDNA, 18.61g of 4,4'-oxydiphthalic anhydride and 1.48g of phthalic anhydride, add it into the hydroxyl-containing diamine solution under stirring, and continue stirring for 4 hours; then, add 30g of toluene to the above In the reaction solution, heat to reflux temperature (120-200° C.), react for 12 hours to distill off part of the toluene and take out the generated water. After the reaction, the reaction solution was poured into 5L of deionized water to precipitate a solid, which was then filtered and vacuum-dried to obtain a hydro...

Embodiment 2

[0102] Embodiment 2, preparation hydroxyl-containing polyimide resin, composition and polyimide film

[0103] In a 500ml three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 220g NMP and 36.57g 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane successively, stir and dissolve at room temperature A diamine solution is formed. Then, 18.56g TDNA, 18.61g 4,4'-oxydiphthalic anhydride and 0.76g phthalic anhydride were added to the diamine solution, and the stirring was continued for 4h; then, 30g toluene was added to the above reaction solution and heated to reflux temperature (120 -200°C), reacted for 12h to distill off part of the toluene and take out the generated water. After the reaction, the reaction solution was poured into 5L of deionized water to precipitate a solid, which was then filtered and vacuum-dried to obtain a hydroxyl-containing polyimide resin A2 with a weight-average molecular weight Mw of 2210...

Embodiment 3

[0106] Embodiment 3, preparation hydroxyl-containing polyimide resin, composition and polyimide film

[0107] In a 500ml three-necked round-bottom flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 220g NMP and 21.51g 1,3-diamino-4,6-dihydroxybenzene in sequence, stir and dissolve at room temperature to form a diamine solution . Then add 23.47g DMDPNA, 18.61g 4,4'-oxydiphthalic anhydride to the diamine solution, then add 0.83g phthalic anhydride, and continue stirring for 4h; then, add 30g toluene to the above reaction solution and heat to reflux Temperature (120-200°C), react for 12h to distill off part of the toluene and take out the generated water. After the reaction, the reaction solution was poured into 5L deionized water to precipitate a solid, which was then filtered and vacuum-dried to obtain a polyimide resin A3 with a weight-average molecular weight Mw of 21500 as measured by GPC.

[0108] In a Class 1000 clean room equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com