Heat-resistant UV viscosity-reducing adhesive tape

A heat-resistant, adhesive tape technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of residual adhesive pollution on the surface of the adherend, large peeling force, difficult peeling, etc., to improve operation Efficiency, improvement of residual glue, and easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

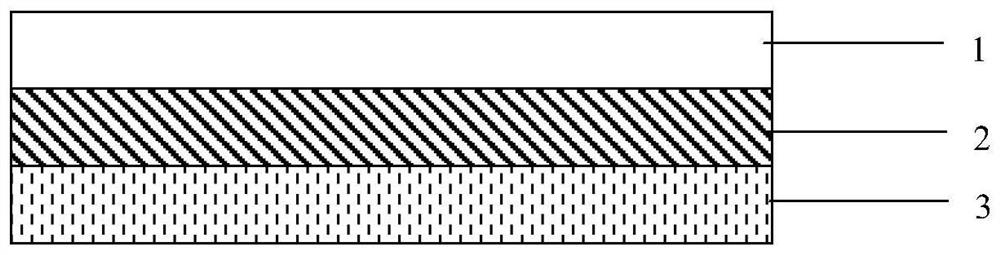

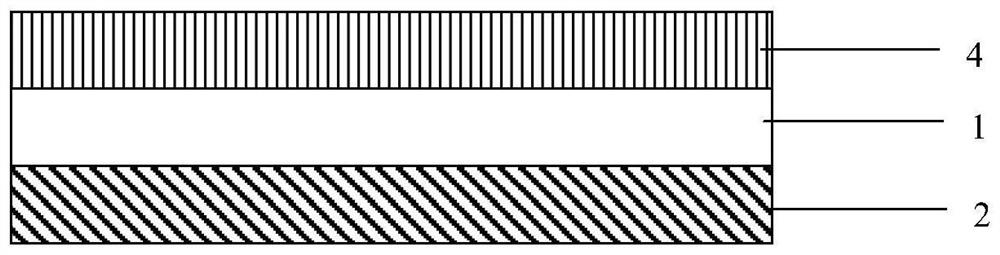

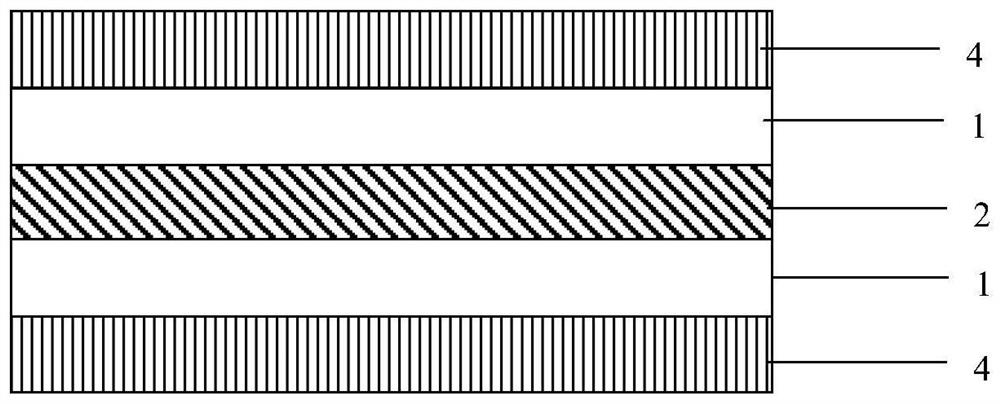

[0052] Use acrylate monomers such as butyl acrylate and acrylic acid. After mixing the monomer components, the polymerization temperature is 60°C. Under the action of the initiator AIBN, the soluble part is obtained by free radical copolymerization in ethyl acetate. The weight-average molecular weight of the acrylic base polymer is 800,000, and the specific formula composition is shown in Table 1; 5 parts by weight, 1 part by weight of curing agent, wherein the photocurable resin is a modified epoxy acrylic resin, and the photoinitiator is specifically 0.9 part by weight of photoinitiator 184, 0.6 part by weight of photoinitiator 127, and the amino resin is Melamine formaldehyde resin, the curing agent is an isocyanate fixing agent (reaction product of trimethylolpropane and toluene diisocyanate, trade name "CORONATE L", abbreviated C / L), and the Young's modulus is 80000Pa under 100 ℃. Adhesive substance; use PO base material to make adhesive tape with adhesive layer 1 thickne...

Embodiment 2

[0057] Using 2-ethylhexyl acrylate, acrylic acid and other acrylate monomers, after mixing the monomer components, the polymerization temperature is 60°C, and the radical copolymerization is carried out in ethyl acetate under the action of the initiator AIBN After obtaining the acrylic base polymer with a weight average molecular weight of 800,000 containing the soluble part, the specific formula composition is shown in Table 1; Parts by weight, 5 parts by weight of amino resin, 1 part by weight of curing agent, wherein, the photocurable resin is modified epoxy acrylic resin, and the photoinitiator is specifically respectively 0.9 parts by weight of photoinitiator 184 and 0.6 part by weight of photoinitiator 127 Weight, amino resin is melamine formaldehyde resin, curing agent is isocyanate fixing agent (reaction product of trimethylolpropane and toluene diisocyanate, trade name "CORONATE L", abbreviated C / L), and Young's Adhesive substance with a modulus of 50000Pa; a tape wit...

Embodiment 3

[0059] Using acrylate-based monomers such as 2-ethylhexyl acrylate and acrylamide, after mixing the monomer components, the polymerization temperature is 60°C, under the action of the initiator AIBN, through free radical copolymerization in ethyl acetate Polymerization obtains the acrylic base polymer with a weight-average molecular weight of 750,000 containing the soluble part, and the specific formula composition is shown in Table 1; Parts by weight, 5 parts by weight of amino resin, 1 part by weight of curing agent, wherein, the photocurable resin is modified epoxy acrylic resin, and the photoinitiator is specifically respectively 0.9 parts by weight of photoinitiator 184 and 0.6 part by weight of photoinitiator 127 Weight, amino resin is melamine formaldehyde resin, curing agent is isocyanate fixing agent (reaction product of trimethylolpropane and toluene diisocyanate, trade name "CORONATE L", abbreviated C / L), and Young's Adhesive substance with a modulus of 50000Pa; a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com