Garnet type solid electrolyte capable of effectively inhibiting lithium dendrites and preparation method of garnet type solid electrolyte

A solid electrolyte and garnet-type technology, which is applied in the manufacture of electrolyte batteries, electrolytes, and non-aqueous electrolyte batteries, etc., can solve problems such as the inability to effectively inhibit the growth of lithium dendrites, intensify the propagation of lithium dendrites, and expand cracks, so as to improve internal Defects, reduced electronic conductivity, and growth-inhibiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

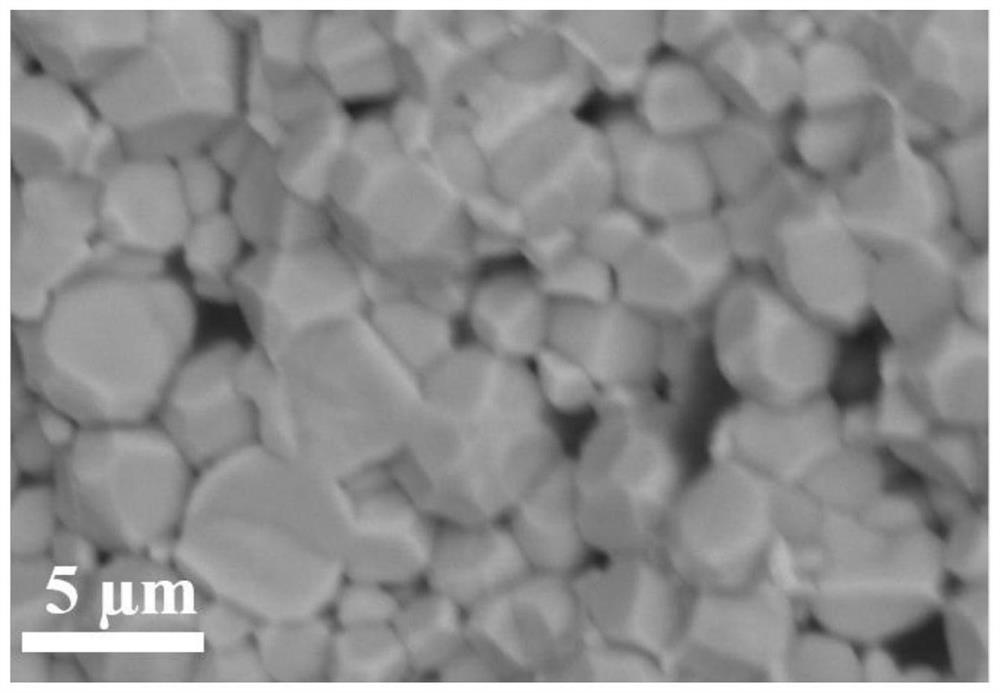

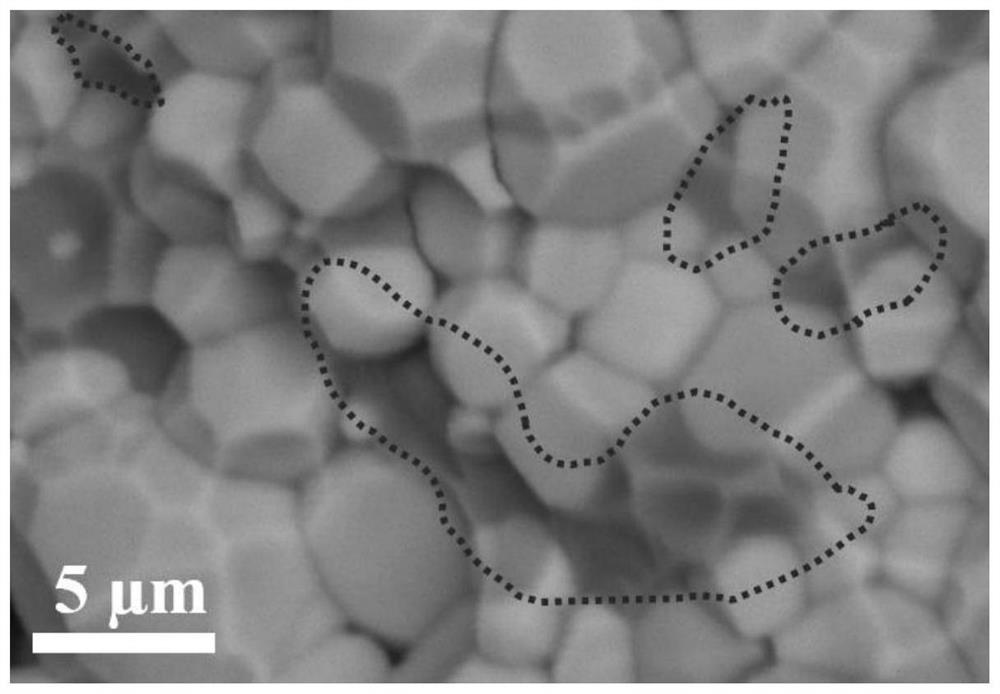

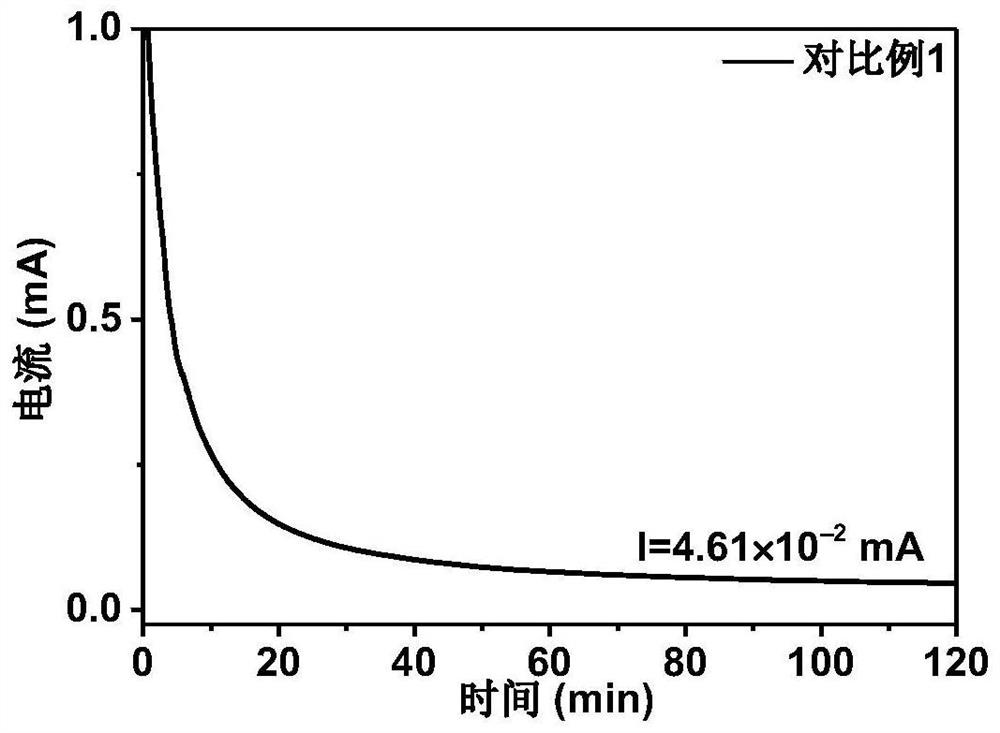

[0034] A method for preparing a garnet-type solid electrolyte that effectively suppresses lithium dendrites, the solid electrolyte has low electronic conductivity at room temperature, comprising the following steps:

[0035] (1) According to the chemical formula Li 7 La 3 Zr 1.5 Ta 0.5 o 12 -xM (LLZTO-xM), the powder of lithium source, lanthanum source, zirconium source and tantalum source is ball milled to obtain raw powder; lithium source needs to be added in excess; the excess quality is 10-10% of the lithium source mass calculated according to the chemical formula 15%; preferably, 2.5%≤x≤15%.

[0036] (2) The raw powder is pre-fired at 750-900°C for 8-10 hours to obtain the initial-fired powder; after this step is pre-fired at a low temperature of 750-900°C, the chemical reaction of the raw powder changes from tetragonal phase to cubic phase.

[0037](3) Weigh a certain mass of initially fired powder, and add a low electronic conductivity material M with a mass fracti...

Embodiment 1

[0051] According to Li 7 La 3 Zr 1.5 Ta 0.5 o 12 -xLiNbO 3 (x=5%) stoichiometric ratio weighs 0.15mol La 2 o 3 , 0.7mol LiOH·H 2 O, 0.15mol ZrO 2 and 0.025mol Ta 2 o 5 , in order to compensate for the volatilization of Li element in the crystal structure at high temperature, the raw material (La 2 o 3 , LiOH·H 2 O, ZrO 2 with Ta 2 o 5 ) in LiOH·H 2 The O excess is 10% by mass based on the stoichiometric ratio. The raw materials were mixed and ball milled in an isopropanol ball milling medium at a speed of 450 r / min for 20 hours, and then dried in an oven at 80° C. for 24 hours to obtain a powder. The obtained powder is ground to uniformity with a mortar, and the masterbatch can be obtained after calcining at 900°C for 9 hours. Take a certain mass of mother powder and a mass fraction of 5% LiNbO 3 , put in a mortar, grind evenly, in a mold with a diameter of 15mm, place the mold on the workbench of the tablet machine, apply a pressure of 400MPa and keep the p...

Embodiment 2

[0053] According to Li 7 La 3 Zr 1.5 Ta 0.5 o 12 -10% LiTaO 3 The stoichiometric ratio weighs 0.15mol La 2 o 3 , 0.7molLiOH·H 2 O, 0.15mol ZrO 2 and 0.025mol Ta 2 o 5 , in order to compensate for the volatilization of Li element in the crystal structure at high temperature, the LiOH·H in the raw material 2 The O excess is 15% by mass based on the stoichiometric ratio. The raw materials were mixed and ball milled in an isopropanol ball milling medium at a speed of 400 r / min for 20 h, and then dried in an oven at 80° C. for 24 h to obtain a powder. The obtained powder is ground to uniformity with a mortar, and the masterbatch can be obtained after calcining at 900°C for 8.5h. Take a certain mass of mother powder and mass fraction of 10% LiTaO 3 , put it in a mortar, grind evenly, in a mold with a diameter of 15mm, place the mold on the table of the tablet machine, apply a pressure of 450MPa and hold the pressure for 5min, then demould and take out the complete green...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com