Metal nitrogen-carbon loaded low-platinum ordered alloy composite catalyst and preparation method thereof

An ordered alloy, metal nitrogen technology, applied in the field of proton exchange membrane fuel cell catalysts, can solve the problems of complex steps, poor durability, poor ORR activity, etc., to improve catalytic activity, improve catalytic activity and stability, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

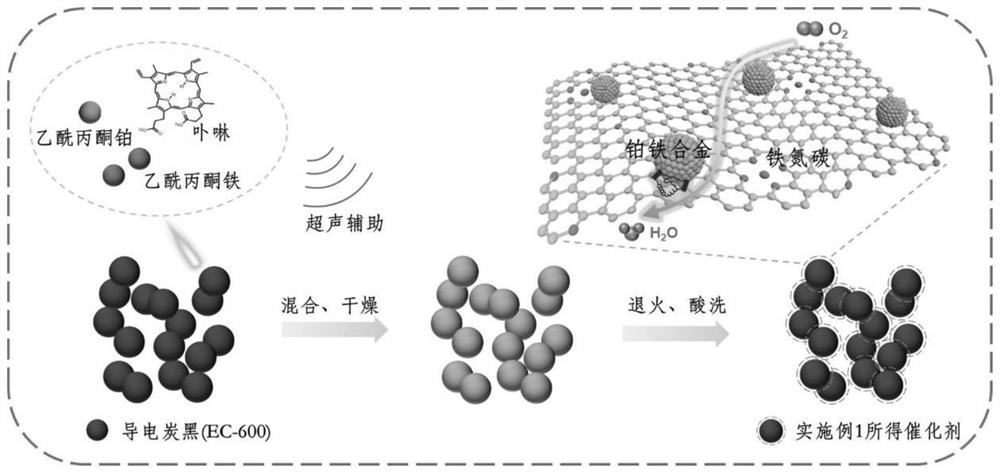

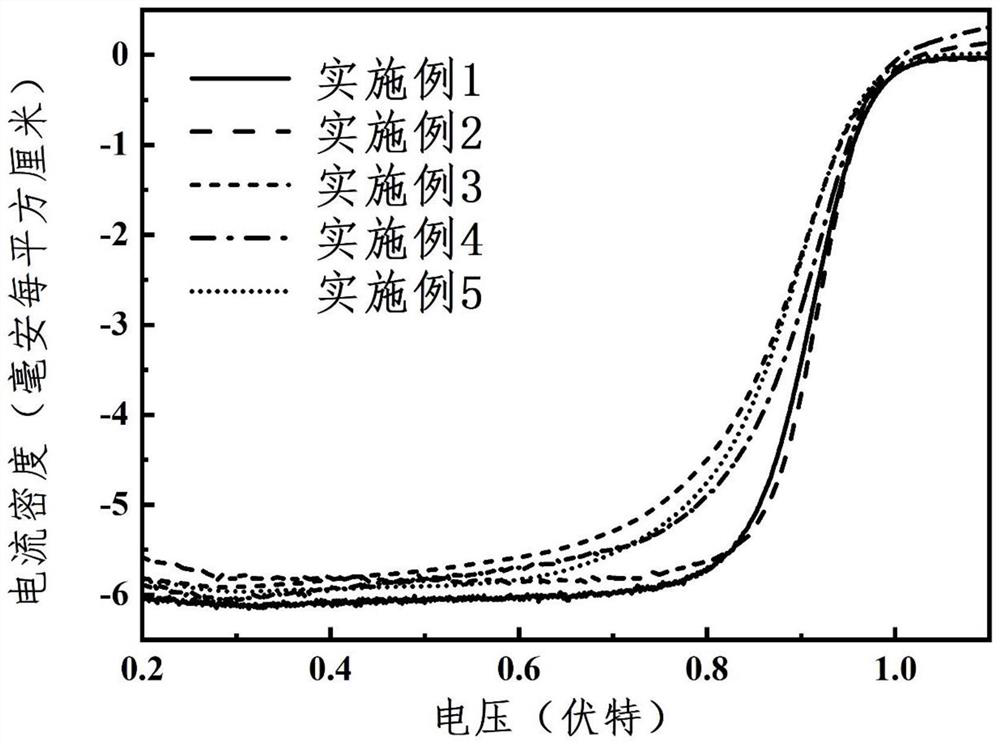

[0033] The PtFe@FeNC composite catalyst of the present invention includes FeNC and a PtFe alloy supported on FeNC, wherein the content of platinum is 2.0%; as figure 1 As shown, the specific preparation steps are as follows:

[0034] (1) Add 4.4 mg of platinum (II) acetylacetonate, 33.5 mg of iron (III) acetylacetonate, and 140 mg of porphyrin to chloroform, and ultrasonically disperse the solution evenly, then add 75 mg of EC-600 conductive carbon black, and ultrasonically obtain a mixture homogeneous solution;

[0035] (2) The above solution is subjected to rotary evaporation treatment, and the solvent is removed, and then dried naturally overnight; the above dried sample is ground into powder, and the temperature is raised to 900°C at a rate of 5°C / min under a nitrogen atmosphere, and the temperature is kept for 2 hours. , naturally cooled to room temperature;

[0036] (3) The above annealed sample was heated in 0.5M H 2 SO 4 After pickling in the solution and suction f...

Embodiment 2

[0038] The PtCo@CoNC composite catalyst of the present invention includes CoNC and a PtCo alloy supported on CoNC, wherein the content of platinum is 5.8%; the specific preparation steps are as follows:

[0039] (1) Add 10 mg of platinum (II) acetylacetonate, 51.4 mg of cobalt (II) acetylacetonate, and 140 mg of porphyrin to chloroform, and ultrasonically disperse the solution evenly, then add 75 mg of EC-600 conductive carbon black, and mix uniformly by ultrasonic The solution;

[0040] (2) The above solution is subjected to rotary evaporation treatment, and the solvent is removed, and then dried naturally overnight; the above dried sample is ground into powder, and the temperature is raised to 900°C at a rate of 5°C / min under a nitrogen atmosphere, and the temperature is kept for 2 hours. , naturally cooled to room temperature;

[0041] (3) The above annealed sample was heated in 0.5M H 2 SO 4 After pickling in the solution and suction filtration, it was naturally dried o...

Embodiment 3

[0043] The PtNi@NiNC composite catalyst of the present invention includes NiNC and a PtNi alloy supported on NiNC, wherein the content of platinum is 8.6%; the specific preparation steps are as follows:

[0044] (1) Add 17.6 mg of platinum (II) acetylacetonate, 51.3 mg of nickel (II) acetylacetonate, and 140 mg of porphyrin to chloroform, and ultrasonically disperse the solution evenly, then add 75 mg of EC-600 conductive carbon black, and ultrasonically obtain a mixture homogeneous solution;

[0045] (2) The above solution is subjected to rotary evaporation treatment, and the solvent is removed, and then dried naturally overnight; the above dried sample is ground into powder, and the temperature is raised to 900°C at a rate of 5°C / min under a nitrogen atmosphere, and the temperature is kept for 2 hours. , naturally cooled to room temperature;

[0046] (3) The above annealed sample was heated in 0.5M H 2 SO 4After pickling in the solution and suction filtration, dry natural...

PUM

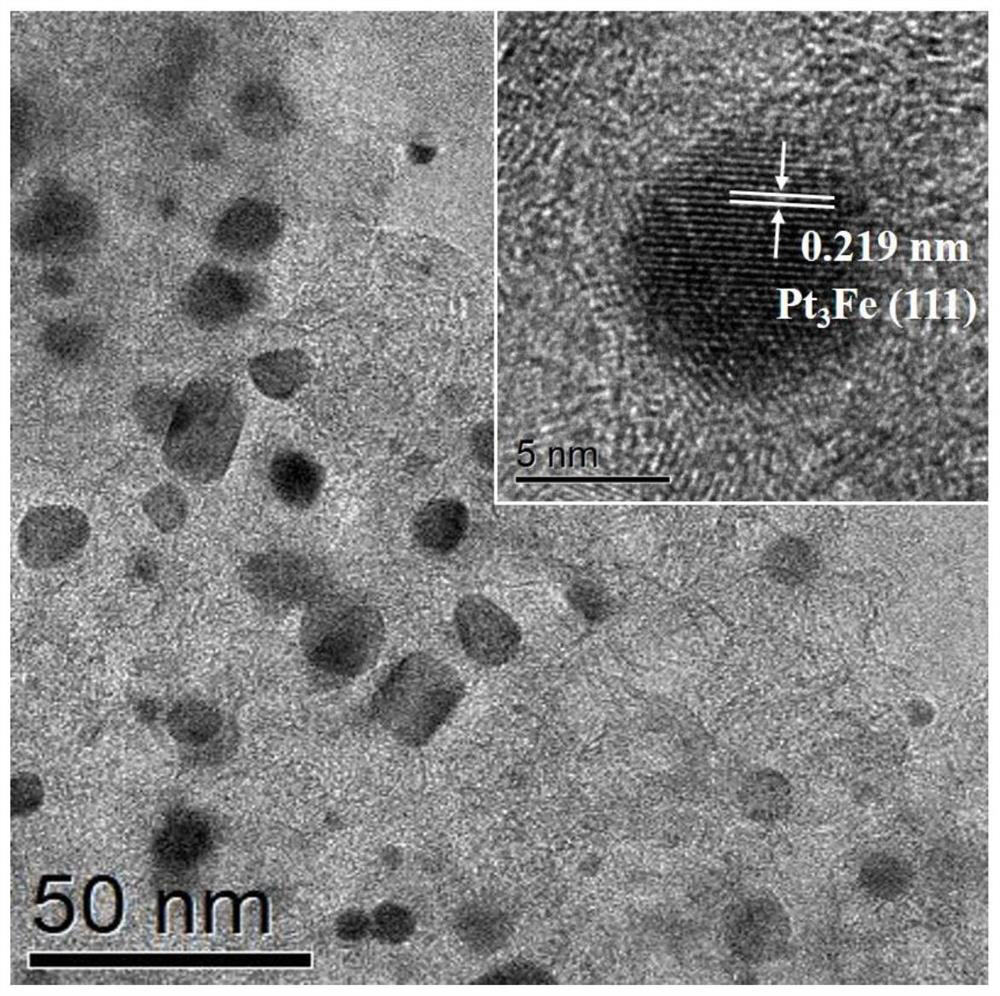

| Property | Measurement | Unit |

|---|---|---|

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com