Motor matrix cascade control circuit

A cascade control and power supply circuit technology, applied in the direction of motor generator control, AC motor control, control system, etc., can solve the problems of no isolation protection, waste of resources, high cost, etc., to improve circuit safety, realize voltage reduction and Noise reduction, increased stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

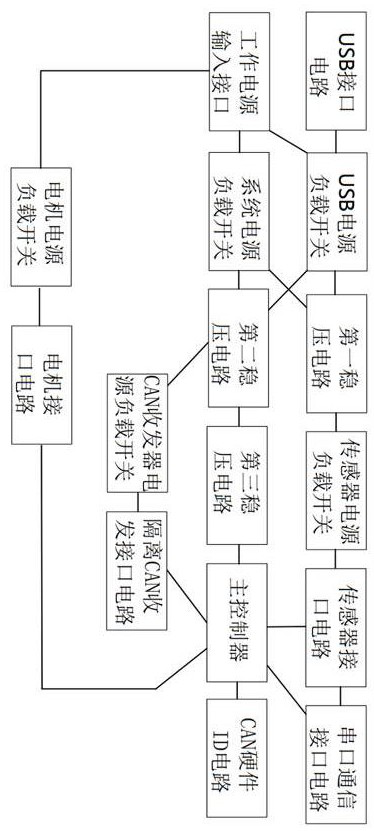

[0034] Such as Figure 1-Figure 5 As shown, this embodiment provides a motor matrix cascaded control circuit, including a power supply circuit and a controller circuit, and the power supply circuit is connected to the controller circuit;

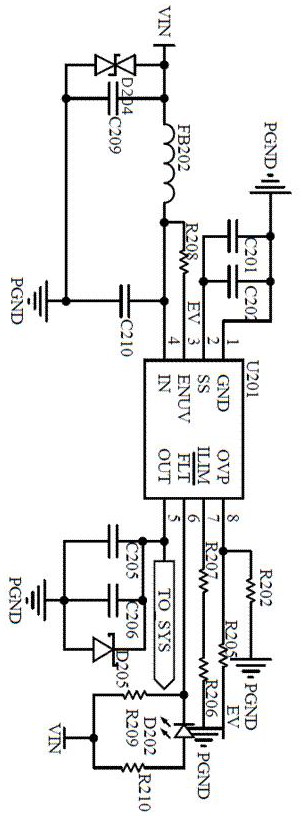

[0035] The power circuit includes a working power input interface, a system power load switch, a motor power load switch, a sensor power load switch, a CAN transceiver power load switch, a first voltage stabilizing circuit, a second voltage stabilizing circuit and a third voltage stabilizing circuit; The working power input interface is respectively connected to the first end of the system power load switch and the first end of the motor power load switch, and the second end of the system power load switch is respectively connected to the first voltage stabilizing circuit The first end of the first voltage stabilizing circuit is connected to the first end of the second voltage stabilizing circuit, the second end of the first voltage stabiliz...

Embodiment approach

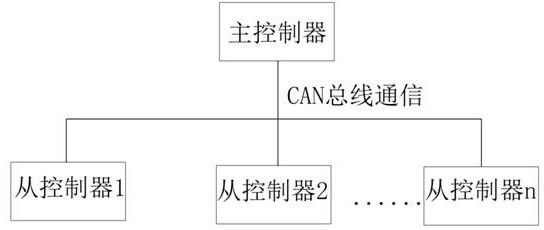

[0058] In a specific implementation, the isolated CAN transceiver interface circuit includes two CAN interface circuits, one of which is a backup circuit for connecting more slave controllers, and each CAN interface circuit includes a dual-way PNP transistor. For driving the CAN signal LED indicator light, wherein, the first collector C1 of the dual-path PNP transistor is connected to the eighth resistor R307 and the second light-emitting diode D305 in turn, and then connected to the system ground SGND, and the first collector of the dual-path PNP transistor is connected to the system ground SGND. A base B1 is connected to the eighth resistor R305 and connected to the CAN1_TX pin of the main controller, and the first emitter E1 of the dual PNP transistor is connected to the 3.3VCAN pin of the main controller. The second collector C2 of the dual PNP transistor is connected to the ninth resistor R304 and the third light-emitting diode in turn, and then connected to the system gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com