Preparation and 3D printing application of vegetable protein-based W/O/W fat

A vegetable protein, 3D printing technology, applied in the direction of edible oil/fat, edible oil/fat phase, edible oil/fat components, etc., can solve the problems of restricting the development of food 3D printing, difficult printing, poor printing performance, etc., to achieve Good plasticity, reduced fat content, simple and fast preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] A method for preparing double-emulsified W / O / W fats that can be used for 3D printing based on nanoscale pea protein, comprising the steps of:

[0094] (1) Using phosphate buffer as a solvent, prepare a pea protein isolate solution with a mass concentration of 10%, stir it at 300rpm for 2 hours, adjust the pH value to 6.7 and place it in a refrigerator at 4°C for 12 hours to obtain a pea protein isolate solution ;

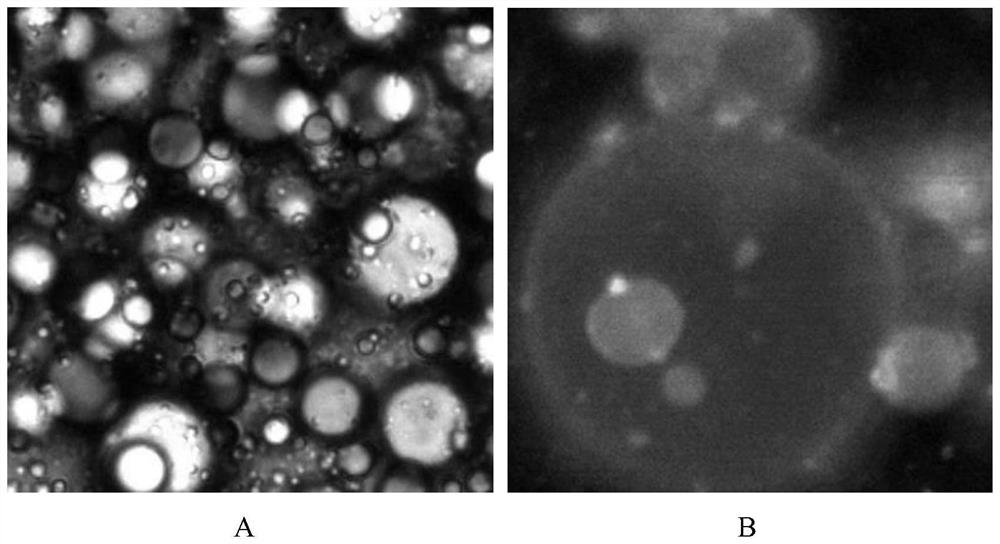

[0095] (2) The hydrated pea protein isolate solution obtained in step (1) is subjected to high-speed shearing (10000rpm treatment for 2 minutes) and high-pressure homogenization (100Mpa treatment for 3 minutes) to obtain a nanoscale pea protein isolate dispersion;

[0096] (3) heating the nanoscale protein isolate dispersion in step (2) in a water bath at 80°C for 20 minutes, then cooling to 40°C to obtain a modified pea protein isolate dispersion;

[0097] (4) Add 15U / g transglutaminase TGase to the pea protein isolate dispersion in step (3), adjust the pH ...

Embodiment 2

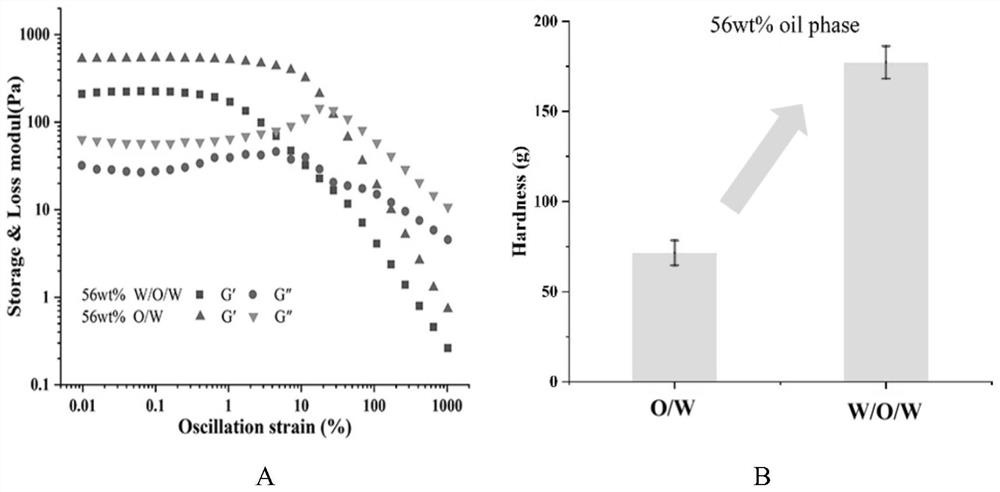

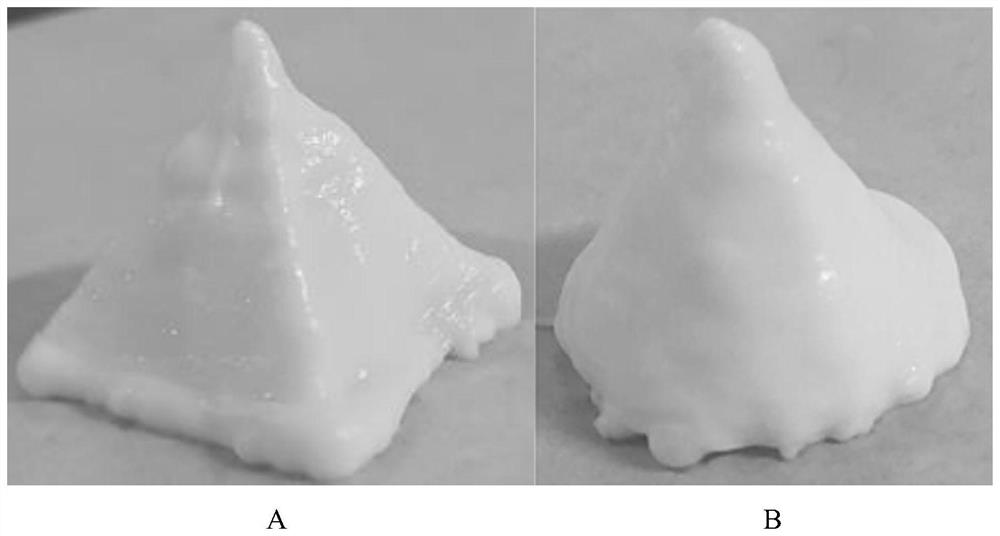

[0114] The double emulsified W / O / W fat of embodiment 1 is used for 3D printing, comprises the steps:

[0115] (1) Fill the double emulsion W / O / W system with an oil phase ratio of 56% obtained in Example 1 into a 3D printing needle with a capacity of 100mL to ensure that the system in the needle is uniform and not dispersed;

[0116] (2) Adjust the temperature in the printing chamber to 25°C, and select a 3D printing nozzle with a diameter of 0.4mm for filling, and set the program to adjust the X, Y, and Z axes of the 3D printer to zero;

[0117] (3) Use the 3ds Max digital model software to design the printing model, generate corresponding layers of three-dimensional slices through the cura slicing software, and obtain the slicing model, and use the programming G code to calculate the path of each slice and finally input it to the printing device;

[0118] (4) Set various parameters in the 3D printing process, as follows: the thickness of the printing layer is 0.2mm, the thick...

Embodiment 3

[0126] A method for preparing 3D printing chocolate based on pea protein double emulsification W / O / W fat-like substitute cocoa butter prepared in embodiment 1, comprising the steps:

[0127] (1) 17.5 g of the W / O / W fat emulsion obtained in Example 1 and 17.5 g of solid cocoa butter were fully stirred and dissolved in a water bath at 70° C. to obtain a 50% emulsion gel-substituted cocoa butter solution for subsequent use;

[0128] (2) The solution obtained in step (1) is mixed with 44.5g powdered sugar, 20g defatted cocoa powder and 0.5g soybean lecithin, all ingredients are placed in a ball mill and mixed, and continuously refined at 600prm for 3h to obtain low-fat Aqueous chocolate mass;

[0129] (3) Fill the system obtained in step (2) into a 3D printing needle tube with a capacity of 100mL to ensure that the system in the needle tube is uniform and not dispersed;

[0130] (4) Adjust the temperature in the printing chamber to 30°C, and select a 3D printing nozzle with a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com