Welding process for one-time brazing forming of parts with different heat capacities

A welding process and component technology, applied in the field of welding process, can solve the problems of flow, incomplete penetration of solder, melting, etc., to achieve the effect of simple production operation and beautiful welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

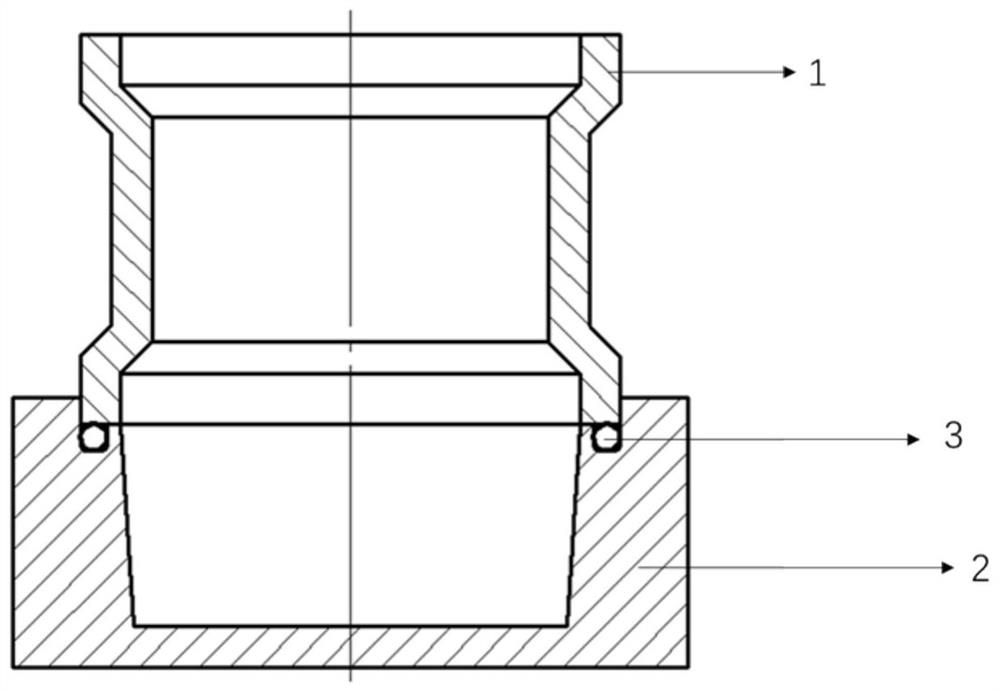

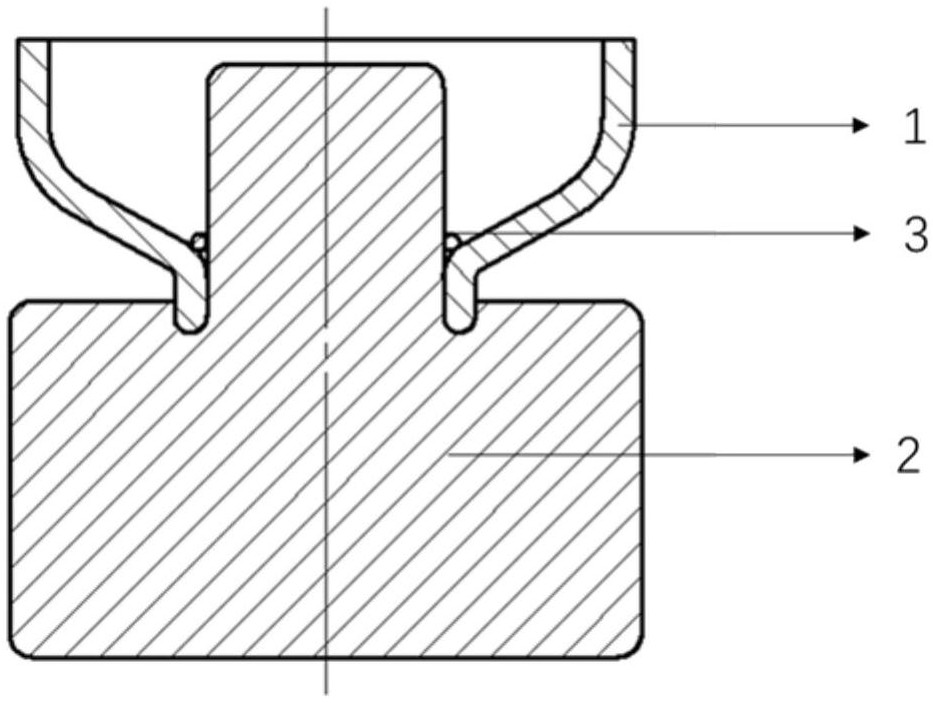

[0044] A welding process for one-time brazing of parts with different heat capacities, comprising the following steps:

[0045] S1. Surface treatment:

[0046] The welding parts of the thin-walled part 1 and the high heat capacity metal substrate 2 are sequentially polished, pickled and cleaned with metallographic sandpaper to remove surface oil, oxidation and residual metal powder particles; use metallographic sandpaper to remove silver-based solder 3 The oxide layer, and then ultrasonic cleaning, the ultrasonic frequency is 300kHz, the ultrasonic power is 800w, and the ultrasonic cleaning time is 10mim;

[0047] Among them, the material of the thin-walled part 1 is Kovar 4J29; the thin-walled part 1 is a thin-walled tube with a diameter of 50mm;

[0048] The material of the high heat capacity metal substrate 2 is oxygen-free copper TU00;

[0049] The silver-based solder 3 is AgCu28 series welding wire, the composition and content of the silver-based solder 3 are: Cu 26wt%,...

Embodiment 2

[0068] A welding process for one-time brazing of parts with different heat capacities, comprising the following steps:

[0069] S1. Surface treatment:

[0070] The welding parts of the thin-walled part 1 and the high heat capacity metal substrate 2 are sequentially polished, pickled and cleaned with metallographic sandpaper to remove surface oil, oxidation and residual metal powder particles; use metallographic sandpaper to remove silver-based solder 3 The oxide layer, and then ultrasonic cleaning, the ultrasonic frequency is 400kHz, the ultrasonic power is 1500w, and the ultrasonic cleaning time is 25mim;

[0071] Wherein, the material of the thin-walled part 1 is stainless steel; the thin-walled part 1 is a thin-walled tube with a diameter of 100mm;

[0072] The material of the high heat capacity metal base 2 is oxygen-free copper TU0;

[0073] The silver-based solder 3 is AgCu28 series welding wire, and the composition and content of the silver-based solder 3 are: Cu 27wt...

Embodiment 3

[0092] A welding process for one-time brazing of parts with different heat capacities, comprising the following steps:

[0093] S1. Surface treatment:

[0094] The welded parts of the thin-walled part 1 and the high-heat-capacity metal substrate 2 are sequentially polished with metallographic sandpaper, pickled and cleaned to remove surface oil, oxidation and residual metal powder particles, and the thin-walled part 1 is nickel-plated, plated The thickness of the nickel layer is 8 μm; the oxide layer on the silver-based solder 3 is removed with metallographic sandpaper, and then ultrasonic cleaning is performed, the ultrasonic frequency is 200kHz, the ultrasonic power is 400w, and the ultrasonic cleaning time is 5mim;

[0095] Among them, the material of the thin-walled part 1 is Kovar 4J29; the thin-walled part 1 is a thin-walled tube with a diameter of 20 mm;

[0096] The material of the high heat capacity metal substrate 2 is oxygen-free copper TU00;

[0097] The silver-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com