Plant bionic high-concentration-salt-resistant solar evaporator device and preparation method and application thereof

A plant bionic and solar energy technology, which is applied in the field of plant bionic anti-high salt solar evaporation devices and its preparation, can solve the problems of affecting light absorption and water vapor escape, high cost of photothermal conversion materials, and obstacles to large-scale production and application. Achieve high light-to-heat conversion efficiency, good light absorption performance, and speed up the escape of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

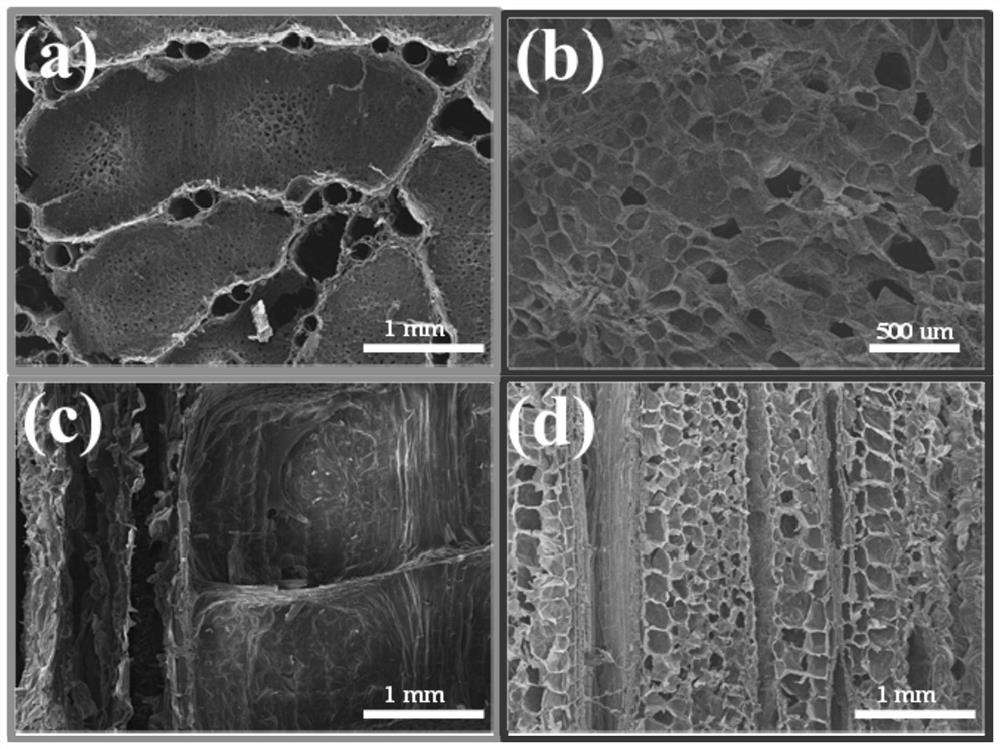

[0037] Embodiment 1: a kind of preparation method of plant bionic anti-high concentration salt solar evaporation device, it comprises the following steps:

[0038] S1. Pre-treatment: select the stalks of reeds, cut them into large pieces along the longitudinal growth direction, freeze them at -25°C for 45 hours, put them into a freeze dryer for 70 hours after freezing, and obtain the stalks;

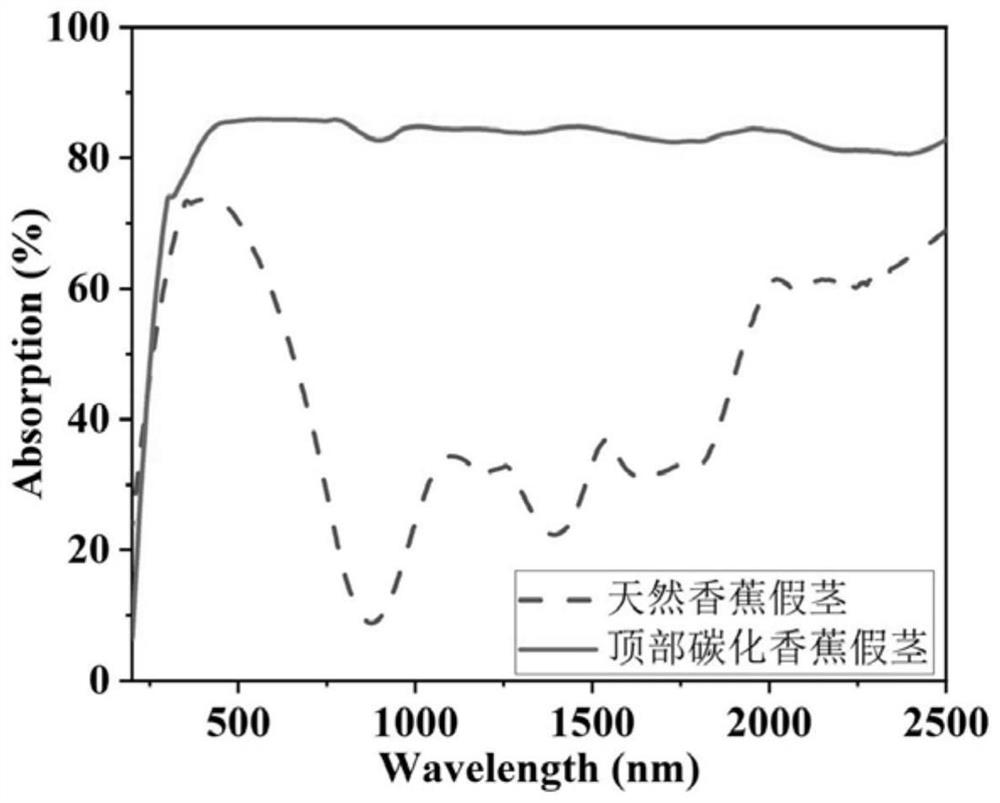

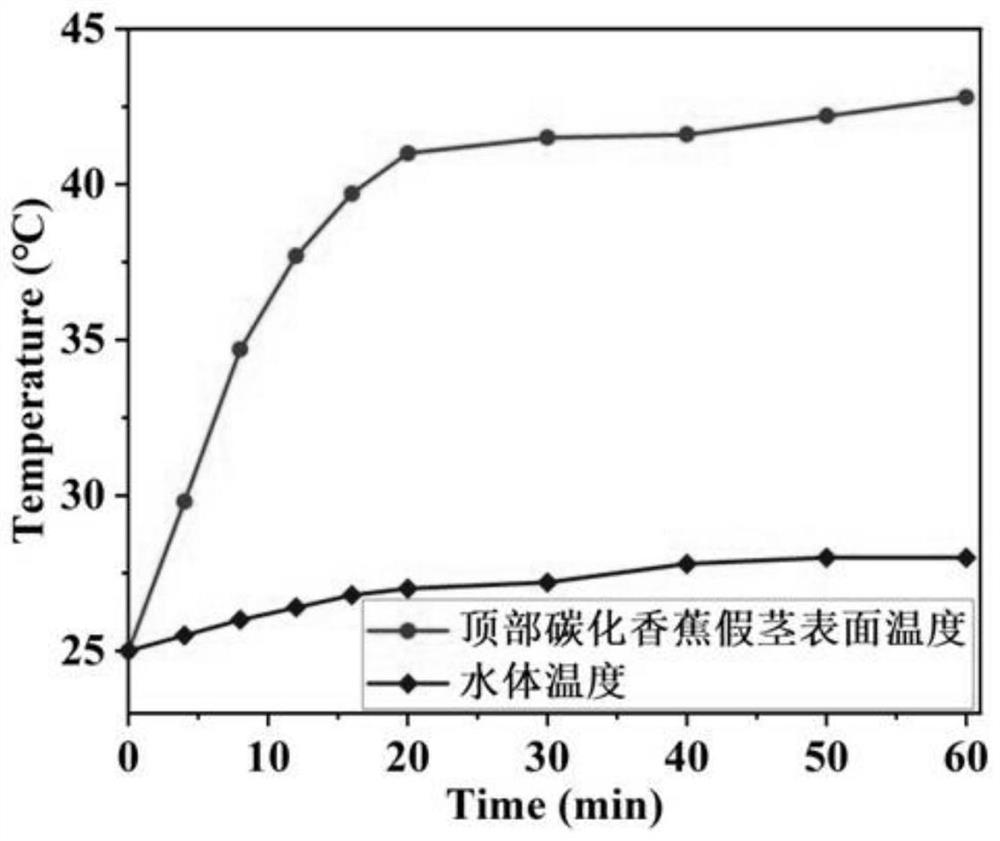

[0039] S2. Stem design: First, bundle the reed stalks so that the top surface area is 3.14cm 2 , a cylinder with a height of 1cm; secondly, punch 8 small holes with a diameter of 0.5mm on the outermost reed stalks to form artificial small holes, and then use the flame of an alcohol lamp to carbonize the top of the pseudostem for 3 minutes to form 1mm thickness of carbon black layer; finally, the cotton thread passes through the artificial small hole to bridge with the salt water of different solution heights and different concentrations on both sides.

Embodiment 2

[0040] Embodiment 2: a kind of preparation method of plant bionic anti-high concentration salt solar evaporation device, it comprises the following steps:

[0041] S1. Pretreatment: select the stalks of plant ramie, cut them into large pieces along the longitudinal growth direction, freeze them at -15°C for 52 hours, put them into a freeze dryer for 80 hours after freezing, and obtain the stalks;

[0042] S2. Stem design: First, bundle the ramie stalks so that the top surface area is 3.14cm 2 , a cylinder with a height of 1cm; secondly, punch 8 small holes with a diameter of 0.5mm on the outermost ramie stalks to form artificial small holes, and then use the flame of an alcohol lamp to carbonize the top of the pseudostem for 4 minutes to form 2mm thickness of carbon black layer; finally, the cotton thread passes through the artificial small hole to bridge with the salt water of different solution heights and different concentrations on both sides.

Embodiment 3

[0043]Embodiment 3: a kind of preparation method of plant bionic anti-high concentration salt solar evaporation device, it comprises the following steps:

[0044] S1. Pre-treatment: select flax stalks, cut them into large pieces along the longitudinal growth direction, freeze them at -18°C for 48 hours, put them in a freeze dryer for 75 hours after freezing, and obtain the stalks;

[0045] S2. Stem design: First, bundle the flax stalks so that the top surface area is 3.14cm 2 , a cylinder with a height of 1cm; secondly, punch 8 small holes with a diameter of 0.5mm on the outermost flax stalks to form artificial small holes, and then use the flame of an alcohol lamp to carbonize the top of the pseudostem for 2 minutes to form 1.5 A carbon black layer with a thickness of mm; finally, a cotton thread is passed through an artificial small hole to bridge with saline with different solution heights and different concentrations on both sides.

[0046] The beneficial effect of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com