High-performance magnesite brick for glass kiln and preparation method of high-performance magnesite brick

A high-performance, glass kiln technology, applied in the field of refractory materials, can solve the problems of adverse environmental impact, deterioration of magnesia raw material quality, inevitable sulfur oxides, etc., to achieve good alkali erosion resistance, excellent creep performance, reduce Effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

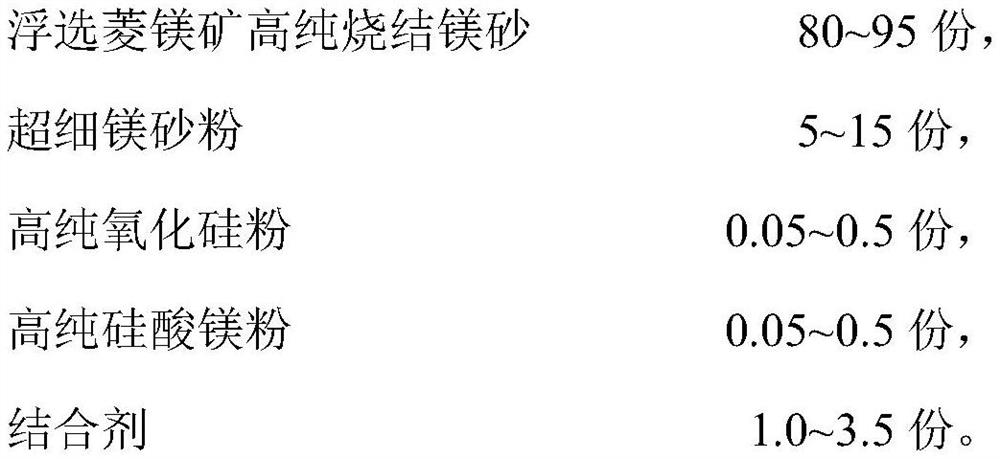

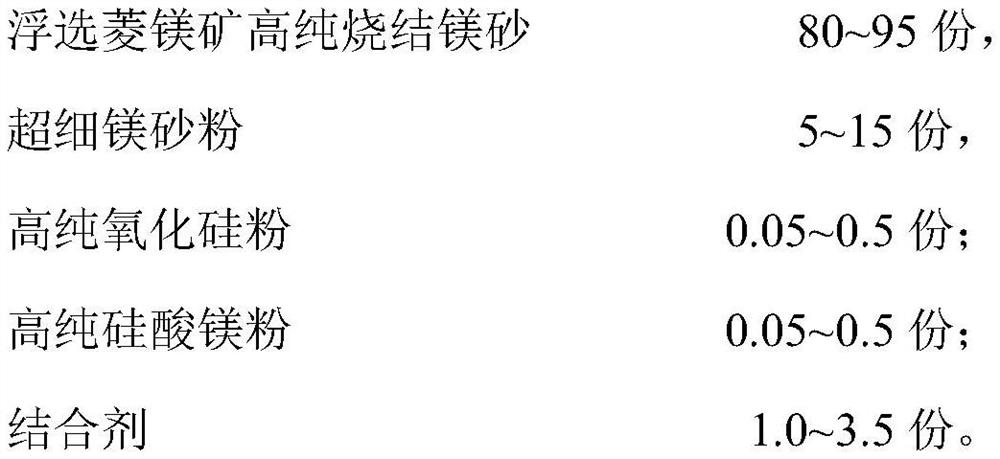

[0028] This embodiment provides a kind of high-performance magnesia brick for glass kiln, and its raw material is composed of: 180kg flotation magnesite high-purity sintered magnesia (40kg 0.096~0.999mm granular magnesia, 100kg 1~3.5mm granular magnesia, 40kg of fine powder magnesia below 0.074mm), 20kg of ultra-fine magnesia powder (MgO content higher than 97.0wt%) with a particle size of 15 μm or less, 0.6 kg of high-purity silica powder with a particle size of 25 μm or less (purity higher than 97.0 wt%), 0.3kg particle diameter is the high-purity magnesium silicate powder (purity is higher than 97.0wt%) below 45 μm, 6kg industrial dextrin and water are mixed into binding agent (concentration is 50wt%). The ultra-fine magnesia powder is obtained by secondary cyclone separation with a pendulum mill.

[0029] This embodiment also provides the preparation method of the high-performance magnesia bricks for the glass kiln, specifically:

[0030] (1) Superfine magnesia powder, hi...

Embodiment 2

[0039] This embodiment provides a kind of high-performance magnesia brick for glass kiln, and its raw material is composed of: 165kg flotation magnesite high-purity sintered magnesia (50kg 0.096~0.999mm granular magnesia, 85kg 1~3.5mm granular magnesia, 30kg of fine powder magnesia below 0.074mm), 15kg of ultra-fine magnesia powder (MgO content higher than 97.0wt%) with a particle size of 15 μm or less, 0.5 kg of high-purity silica powder with a particle size of 25 μm or less (purity higher than 97.0 wt%), 0.3kg particle diameter is the high-purity magnesium silicate powder (purity is higher than 97.0wt%) below 45 μ m, and the industrial dextrin of 5.5kg is mixed with water to form binding agent (mass concentration is 50wt%). The ultra-fine magnesia powder is obtained by secondary cyclone separation with a pendulum mill.

[0040] This embodiment also provides the preparation method of the high-performance magnesia bricks for the glass kiln, specifically:

[0041] (1) Ultrafin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com