Eutectic high-entropy alloy and preparation method thereof

A high-entropy alloy and alloy technology, applied in the field of metal materials, can solve the problems of difficulty in obtaining large-size alloy ingots with uniform composition, restrictions on the industrial application and development of alloys, and the lack of castability of single-phase HEA, achieving a strong combination , good thermal stability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail now in conjunction with accompanying drawing.

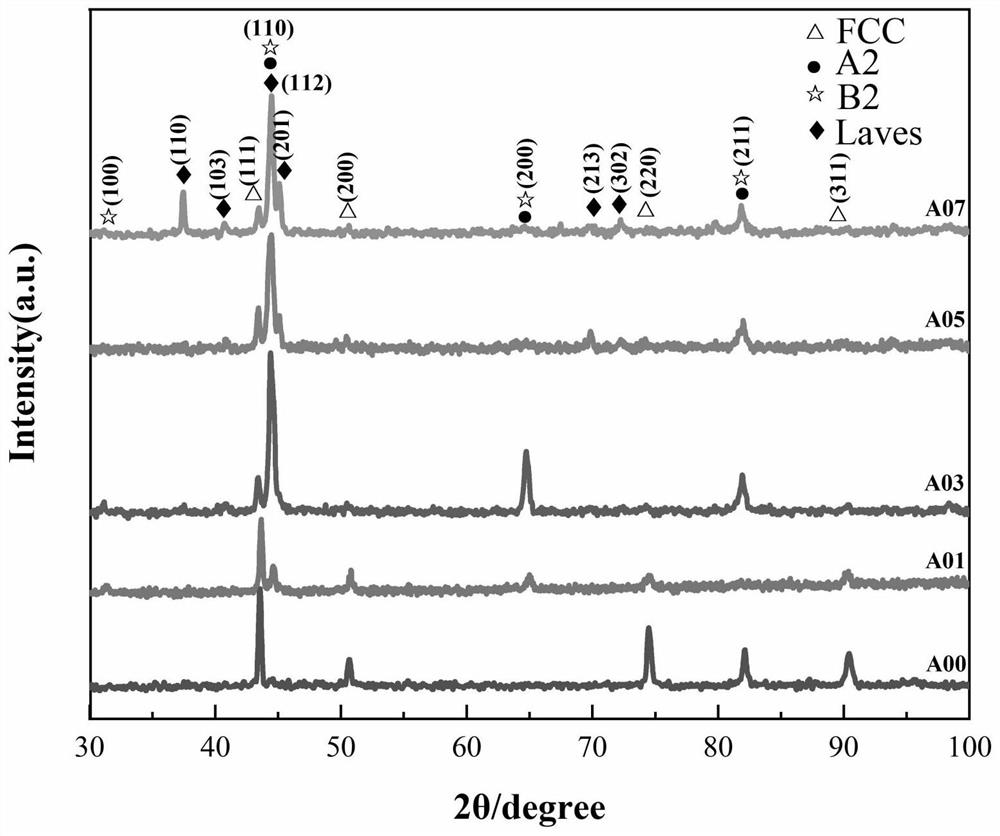

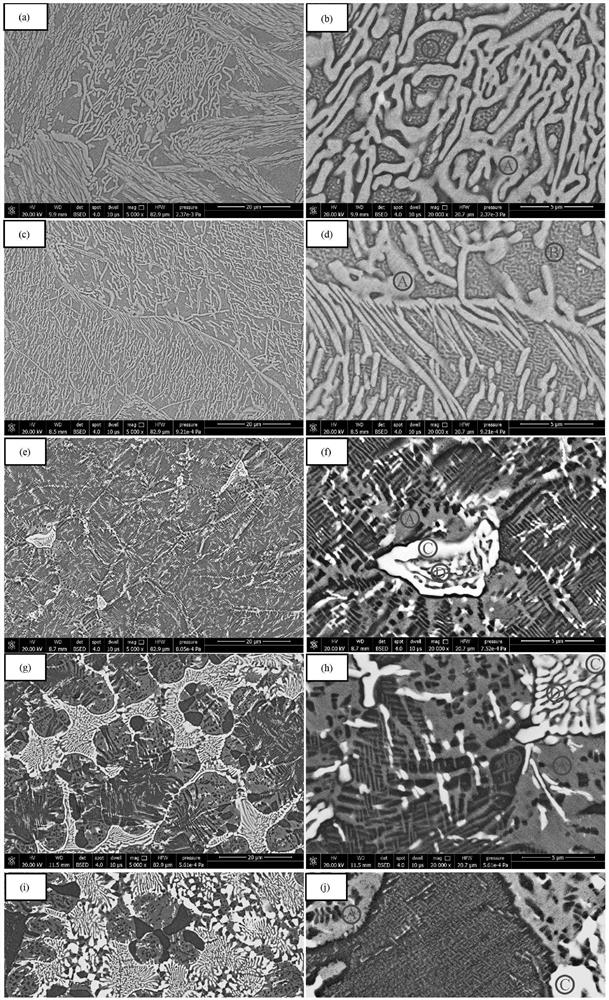

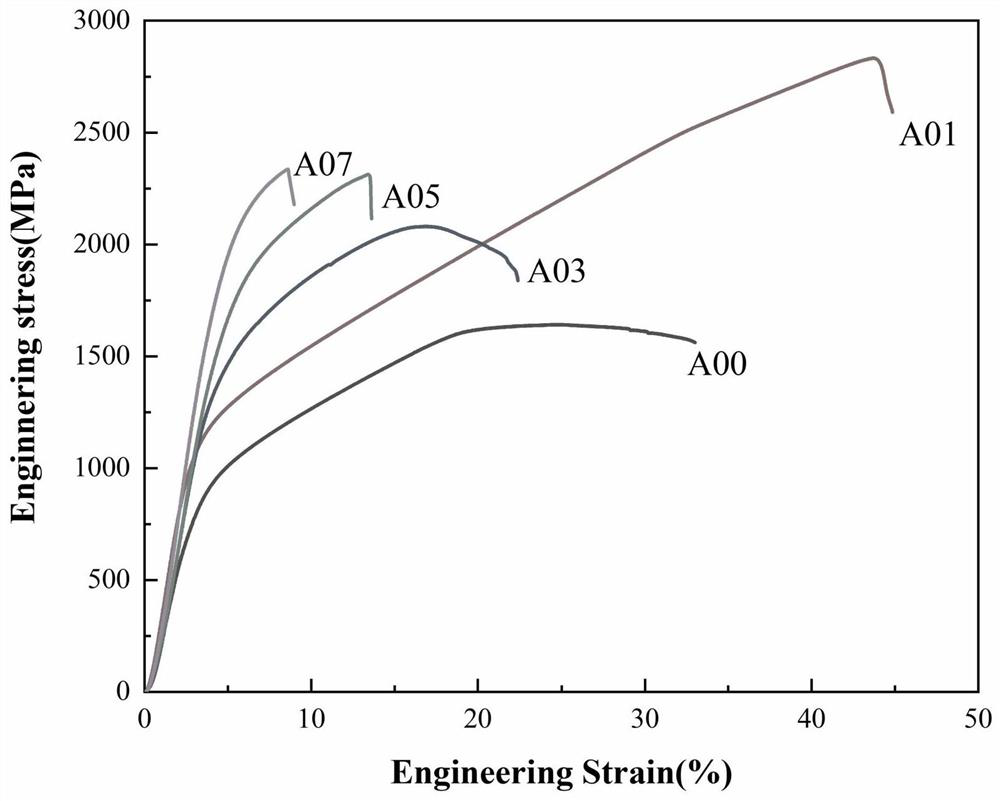

[0030] an AlCrFe 2 Ni 2 (MoNb) x Eutectic high-entropy alloy, the mole percentage of each element is Al:Cr:Fe:Ni:Mo:Nb=1:1:2:2:x:x, x=0,0.1,0.3,0.5,0.7).

[0031] Its preparation method includes:

[0032] Step 1. Preparation of raw materials: According to the composition ratio of the eutectic high-entropy alloy, metal Al, metal Cr, metal Fe, metal Ni, metal Mo and metal Nb are weighed as raw materials, and the molar percentage of each element is converted to Al:Cr: Fe: Ni: Mo: Nb=1: 1: 2: 2: x: x, x=0, 0.1, 0.3, 0.5, 0.7, respectively make 5 samples whose quality is 30g, so that the present invention adopts The raw materials are high-purity metal Al, metal Cr, metal Fe, metal Ni, metal Mo and metal Nb, the purity of which is greater than 99.9%. The oxide skin on the surface of the raw material is removed, and the industrial ethanol is used for ultrasonic cleaning and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com