Heating body for ultra-high temperature field platform and preparation method and application of heating body

A heating body, ultra-high temperature technology, applied in chemical instruments and methods, electric heating devices, heating element materials, etc., can solve the problems of inability to achieve temperature field construction, insignificant Joule heating effect, low resistivity of graphene, etc., and achieve Joule heating effect. Rapid, broad application prospects, precise and controllable temperature field effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

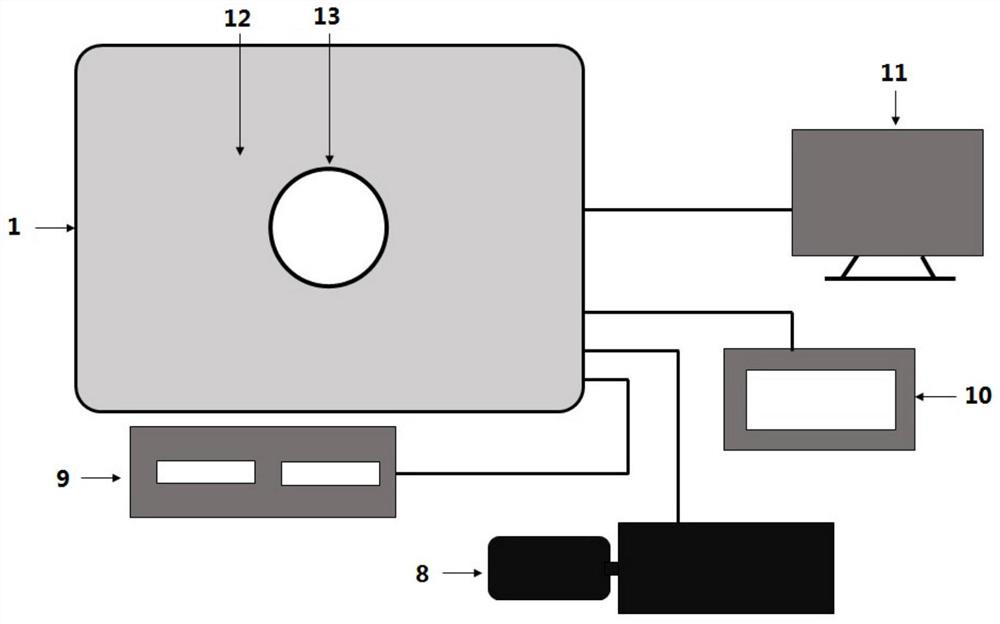

[0043] A heating element for an ultra-high temperature temperature field platform, the heating element is a pre-reduced graphene oxide film, wherein the pre-reduced graphene oxide film is prepared by heat-treating graphene oxide nanosheets.

[0044] In this embodiment, the length of the pre-reduced graphene oxide film is 5 mm, the width is 0.5 mm, and the thickness is 10 μm.

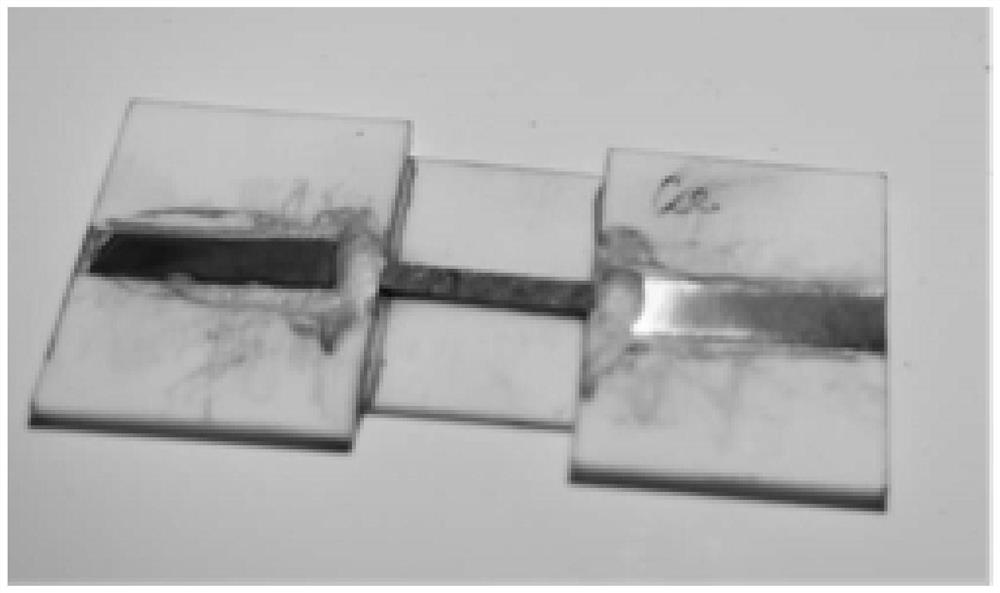

[0045] In this embodiment, a high-temperature-resistant carrier material is also included, and the pre-reduced graphene oxide film is fixed on the high-temperature-resistant carrier material, wherein the high-temperature-resistant carrier material is an alumina ceramic material.

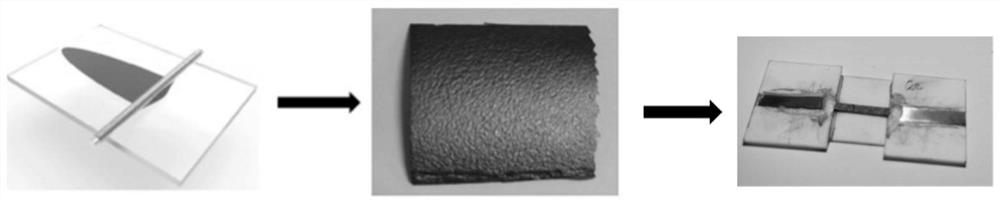

[0046] A method for preparing a heating element for an ultra-high temperature temperature field platform in the above-mentioned present embodiment, such as figure 1 shown, including the following steps:

[0047] (1) Mix graphene oxide nanosheets with a sheet diameter of 40 μm to 50 μm with water to prepare an aqueous solution ...

Embodiment 2

[0079] A heating element for an ultra-high temperature temperature field platform, which is basically the same as in Example 1, except that in Example 2, the length of the pre-reduced graphene oxide film is 5 mm, the width is 0.5 mm, and the thickness is 25 μm.

[0080] A method for preparing a heating element for an ultra-high temperature temperature field platform is basically the same as that of Example 1, the only difference being that in Example 2, the distance between the scraper and the substrate is 3mm. In this embodiment, it can be scraped several times until the target thickness is reached.

[0081] The heating element in Example 2 was used as a heat source to construct an ultra-high temperature temperature field platform.

Embodiment 3

[0083] A heating element for an ultra-high temperature temperature field platform, which is basically the same as in Example 1, except that in Example 3, the length of the pre-reduced graphene oxide film is 5 mm, the width is 0.5 mm, and the thickness is 100 μm.

[0084] A method for preparing a heating element for an ultra-high temperature temperature field platform is basically the same as that of Example 1, the only difference being that in Example 3, the distance between the scraper and the substrate is 4mm. In this embodiment, it can be scraped several times until the target thickness is reached.

[0085] The heating element in Example 3 was used as a heat source to construct an ultra-high temperature temperature field platform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com