Flame brazing control method for copper and aluminum welding and automatic welding machine

A technology of flame brazing and control method, applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc. Improve pass rate, improve welding efficiency, overcome the effect of over-burning or under-burning of aluminum parts or uneven penetration of solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

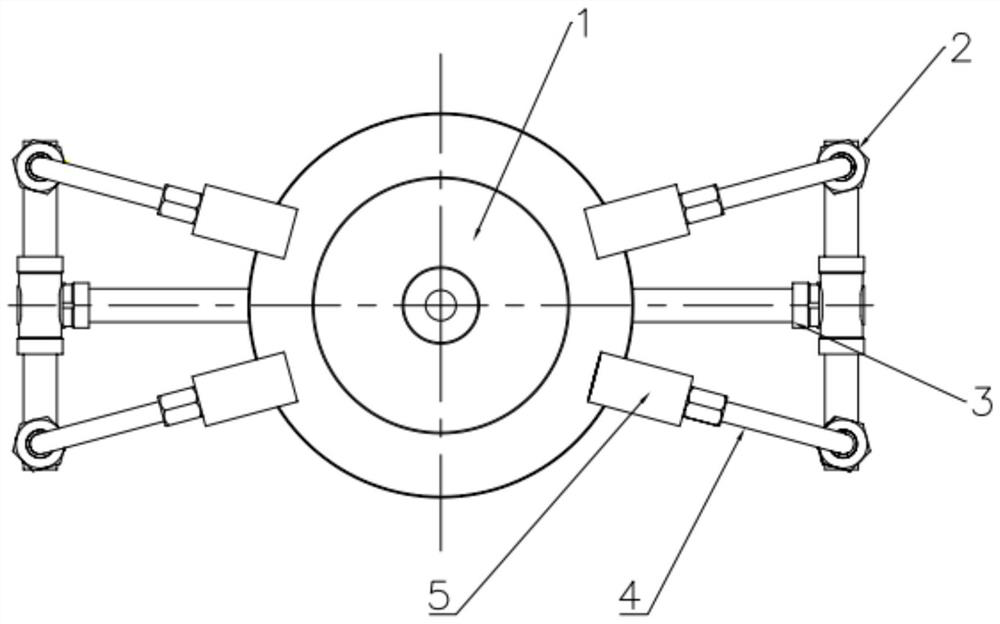

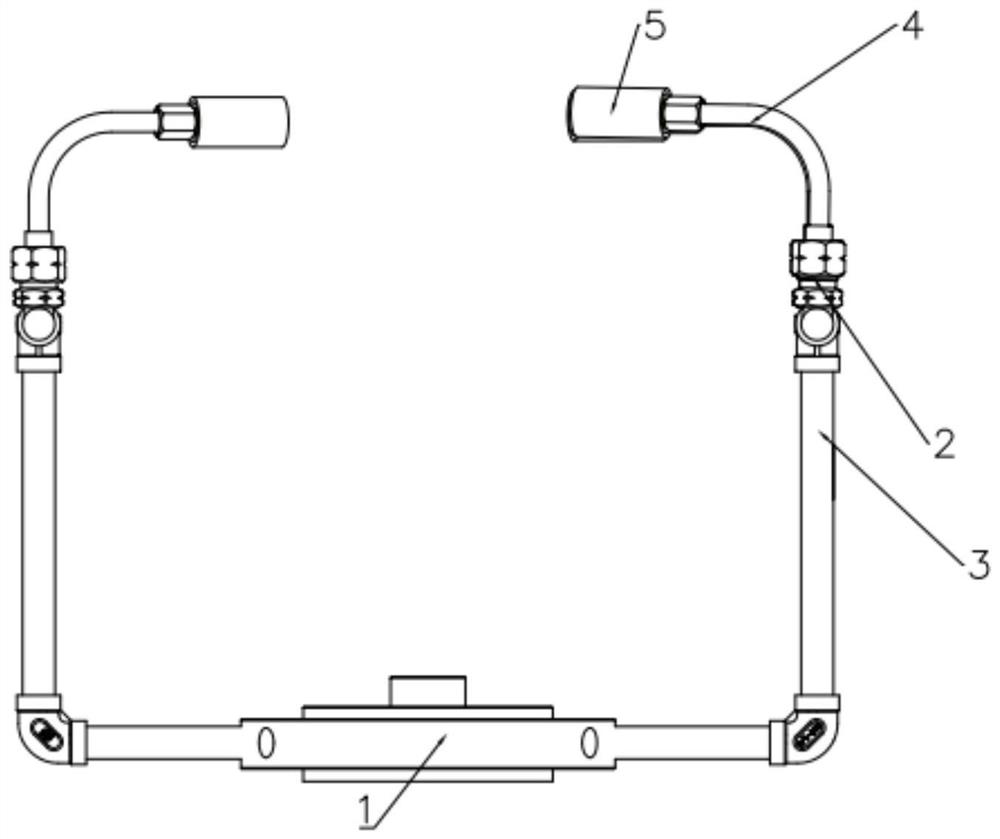

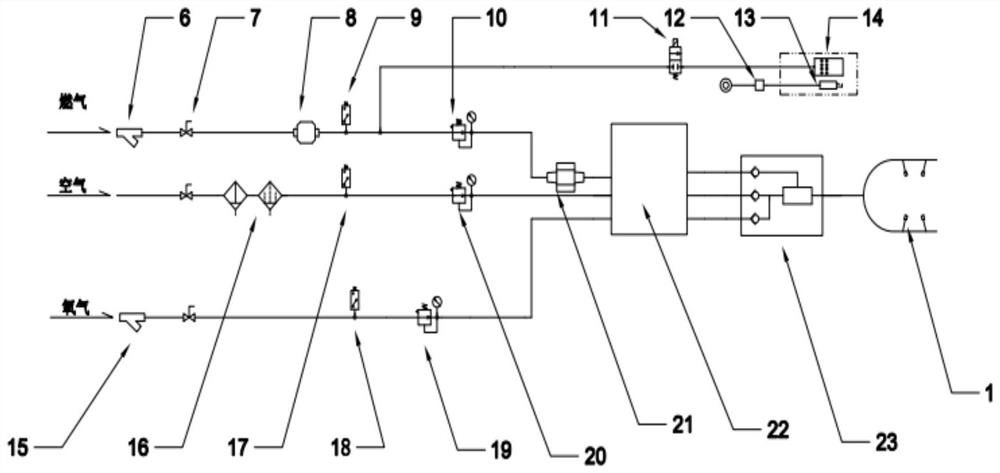

[0037] On the automatic flame brazing machine, the flame of the combustion of natural gas, air and oxygen is used as a heat source, 4 air nozzles, natural gas flow to 7 l / min, and air flow is set to 118L / min, and the oxygen flow is set to 6 L / min. Use an aluminosilicone core welding wire, copper aluminum solder paste. The four air nozzles with suitable spacing were soldered with the aluminum base with the aluminum base with the aluminum base. Preheating copper tube 6 seconds, preheating aluminum base for 14 seconds, free wire welding time for 6 seconds. A total of 26 seconds.

Embodiment 2

[0043] On the automatic flame brazing machine, the flame of natural gas and air and oxygen is mixed into the heat source, and the natural gas flow is set to 3.5 L / min, and the air flow is set to 70 l / min, and the oxygen flow is set to 7 l / min. The pipe diameter 19 mm copper tube is heated to 600 degrees by a 10 mm swing distance from the two air nozzles of 110 mm. Time 11 seconds. Photo of the color change of the copper tube after cooling Figure 4 (b).

Embodiment 3

[0049] On the automatic flame brazing machine, the combustion of the combustion of natural gas, air and oxygen is used as a heat source, 4 air noise, and natural gas flow is set to 7 l / min, and the air flow is set to 140 l / min, and the oxygen flow is 14 L / min. Preheating copper tube 5 seconds, immediately switchable natural gas flow rate of 7 l / min, air flow is 140 l / min, and the oxygen flow is 7 l / min, the preheating aluminum base is 13 seconds, and then immediately switch into natural gas flow rate 7L. / min, air flow 140L / min, mixed gas combustion heating welding area for oxygen flow 5.6 l / min for 5.5 seconds. Use an aluminosilicone core welding wire, copper aluminum solder paste. The tube diameter 19 mm copper tube is brazed with the aluminum tube base with a wobble distance of 10 mm with the same suitable spacing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com