A kind of method for preparing optical fiber cladding optical filter based on electroless ni-p method

An optical fiber cladding and chemical plating technology, applied in the laser field, can solve the problems of limiting the performance of the cladding light filter, difficult to stabilize the cladding light filtering, and the temperature of the light guide glue is too high, so as to overcome the burning or falling off, the coating Good quality and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

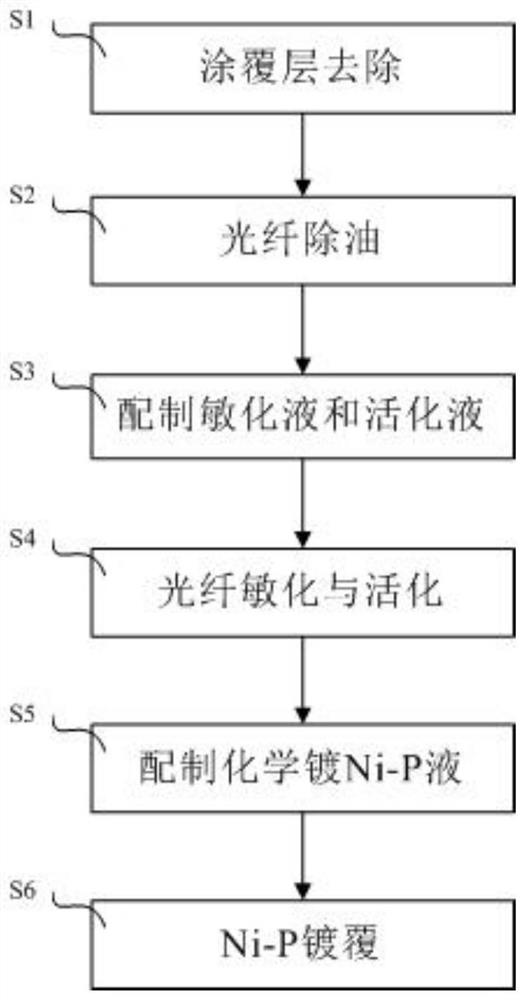

[0042] as per figure 1 The process shown in the preparation of optical fiber cladding optical filter, the specific steps are as follows:

[0043]S1. Take an optical fiber with a length of 2m, soak a 20cm-long section of the middle part of the optical fiber in acetone for 15min, and then wash it with concentrated H 2 SO 4 Soak for 1 minute to remove the coating layer, and then wash it with 95% alcohol for 5 minutes to obtain a section of optical fiber from which the coating layer has been removed;

[0044] S2: Optical fiber degreasing: Remove the coated optical fiber from this section and soak it in 40g / L NaOH solution for 15 minutes to degrease and decontaminate. Finally, wash it once with 95% alcohol and dry it for later use;

[0045] S3. Prepare sensitization solution and activation solution, the composition of sensitization solution is SnCl 2 15g / L, 37% HCl 30ml / L, the activation solution is PdCl 2 0.5g / L, 37% HCl 5ml / L, heat the sensitizing solution to 25°C, and heat...

Embodiment 2

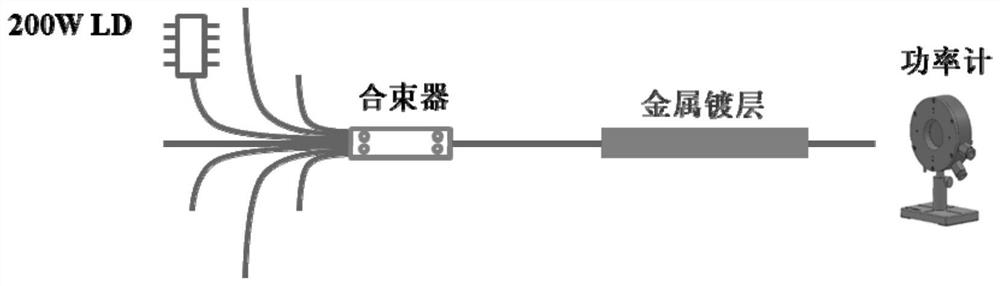

[0053] Embodiment 2 Performance detection of optical fiber cladding optical filter

[0054] The optical fiber with the optical fiber cladding optical filter prepared in embodiment 1 and the 200W LD pumping light source and the 7×1 beam combiner device are as follows image 3 For the connection shown, use a 300W power meter to detect the output power of the laser after being processed by the fiber cladding optical filter. During the test, the laser light generated by the LD is coupled by the beam combiner device, enters the optical fiber with the optical fiber cladding filter, and finally enters the power meter. During the test, the surface temperature of the chemically plated Ni-P part of the optical fiber is monitored by an infrared thermal imager. When the test is selected when the surface temperature is 100°C, the passing power of the chemically plated Ni-P fiber is recorded, and the pumping power of the chemically plated Ni-P fiber is calculated. light transmission rate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com