Cutting process method of quartz wafer

A quartz wafer and cutting process technology, which is applied in the field of prefabricating microcracks on the surface of quartz wafers to cut quartz wafers, can solve problems such as edge effects and asymmetric cutting track offsets, and achieves solutions to edge effects and asymmetric cutting tracks. The effect of offset, improving work efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

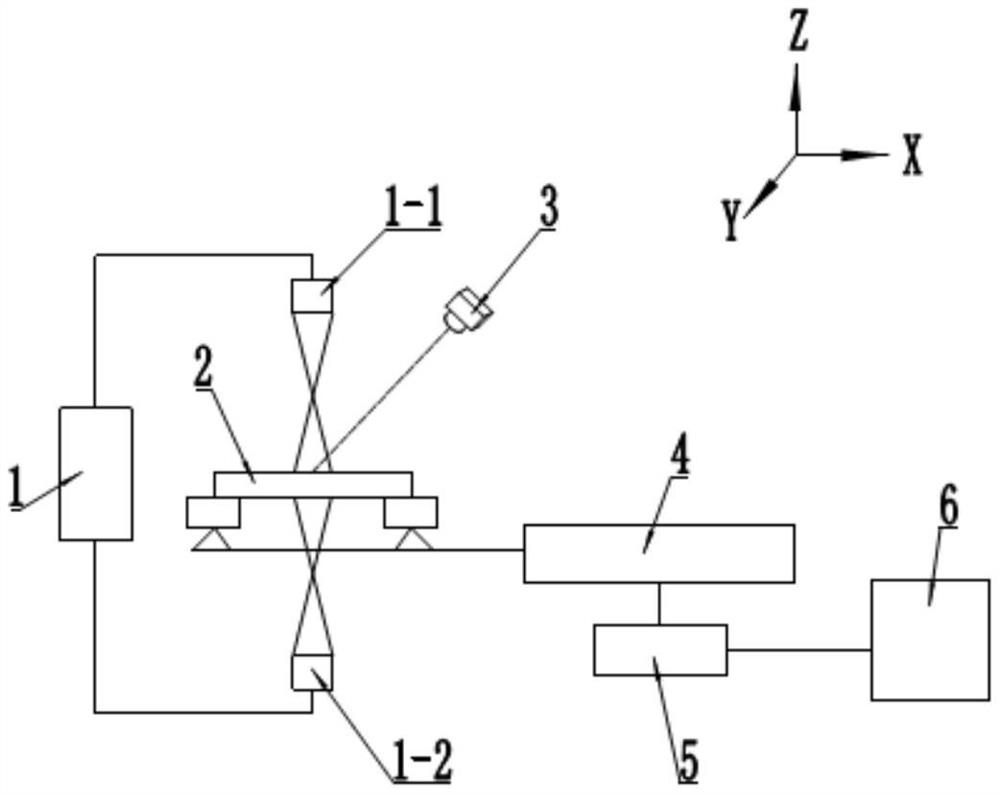

[0019] The invention provides a quartz wafer cutting process method, which first uses an ultra-thin diamond grinding wheel to prefabricate microcracks on the surface of the quartz wafer, then pretreats the surface of the quartz wafer through a mixed solution, and then under the guidance of the prefabricated microcrack track, The stress change caused by the local thermal expansion generated by the laser is used to expand the prefabricated crack to realize the cutting of the quartz wafer. The specific operation steps are as follows:

[0020] a. Use an ultra-thin diamond grinding wheel with a thickness of 13 μm to prefabricate microcracks with a width of 16 μm and a depth of 73 μm on the surface of the quartz wafer to meet the requirements for the slit width of the silicon wafer dicing;

[0021] B, carry out pretreatment to quartz wafer surface with acidic mixed solution, described acidic mixed solution component and weight ratio are HF: HNO3: H 2 O=1:2:30, through the corrosion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com