Preparation method of titanium dioxide aerogel

A technology of titanium dioxide and airgel, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of high cost, unsuitable for mass production, complexity, etc., and achieve simple, feasible and widely practical preparation process The effect of application value and industrial production prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

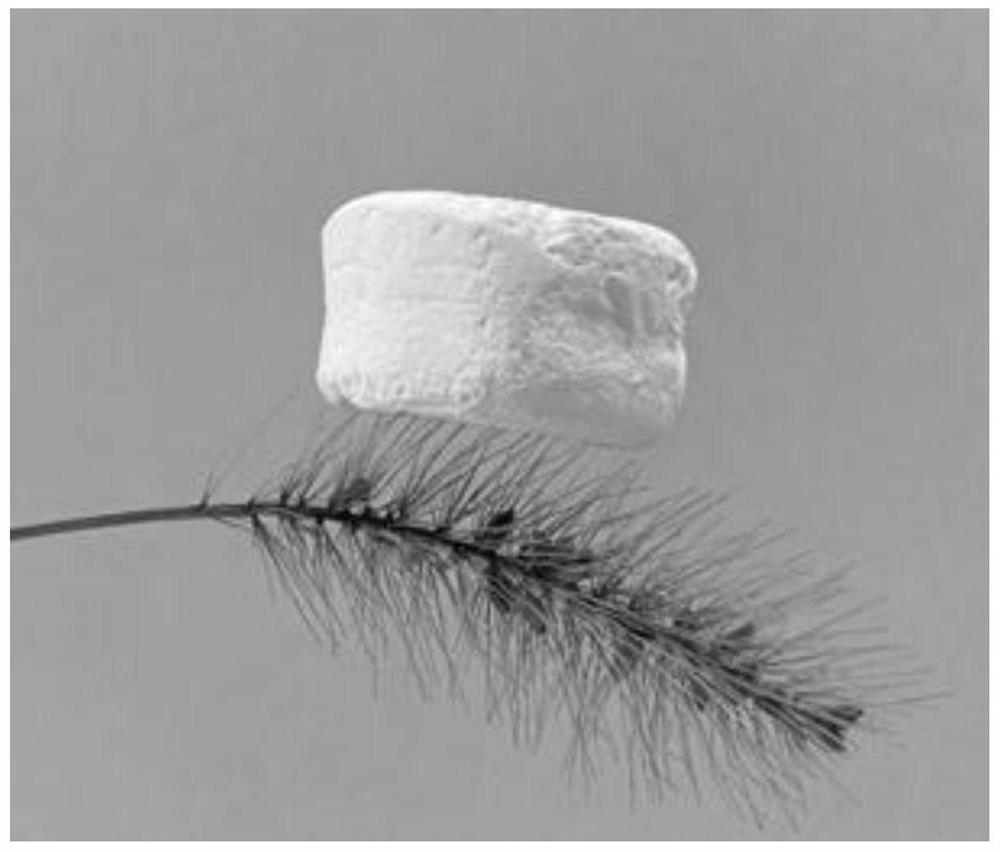

Image

Examples

preparation example Construction

[0021] The preparation method of titanium dioxide airgel of the present invention, comprises the steps:

[0022] Step 1. A certain amount of titanium dioxide powder is used as raw material, placed in a certain volume and a certain concentration of NaOH aqueous solution, and ultrasonically treated for a certain period of time, followed by hydrothermal synthesis at a certain temperature, and then the obtained white block product is used to remove Wash several times with ionized water, then soak in a certain concentration of low surface energy organic reagent (such as: acetone, methanol, ethanol, etc.) Glue precursor;

[0023] Step 2, placing the titanium dioxide airgel precursor in a muffle furnace for heat treatment at a certain temperature for a certain period of time to obtain the titanium dioxide airgel.

[0024] The quality of titanium dioxide powder described in step 1 is 2~3g; The volume of described NaOH aqueous solution is 100mL; Concentration is 5~10mol / L; The time of...

Embodiment 1

[0028] Weigh a certain amount of NaOH at room temperature, dissolve it in a certain amount of deionized water, and prepare a 10mol / L NaOH aqueous solution; then place 2g of titanium dioxide powder in the above-mentioned 100mL NaOH aqueous solution, ultrasonically treat it for 20min, and then transfer the mixture to water Heat the reaction kettle; then place it in an oven at 200°C for 24 hours; after the reaction kettle is naturally cooled, wash the white block product with deionized water for 5 times; then place it in an aqueous ethanol solution with a volume fraction of 100%. 24 hours; drying in an oven at 200°C for 2 hours to obtain a titanium dioxide airgel precursor. The titania airgel precursor was placed in the central position of the muffle furnace, and in the air atmosphere, the reaction time was 1h at a constant temperature of 600°C (the heating rate from room temperature to the set temperature was 10°C / min), and the titania gas was prepared. gel. The obtained titani...

Embodiment 2

[0030] Weigh a certain amount of NaOH at room temperature, dissolve it in a certain amount of deionized water, and prepare an 8mol / L NaOH aqueous solution; then place 3g of titanium dioxide powder in the above-mentioned 100mL NaOH aqueous solution, sonicate for 10min, and then transfer the mixture to water Heat the reaction kettle; then place it in an oven at 180°C for 24 hours; after the reaction kettle is naturally cooled, wash the white block product with deionized water for 4 times; then place it in an aqueous solution of acetone with a volume fraction of 60%. 24 hours; drying in an oven at 180°C for 1 hour to obtain a titanium dioxide airgel precursor. The titanium dioxide airgel precursor was placed in the central position of the muffle furnace, and in the air atmosphere, the reaction time was 2h at a constant temperature of 600°C (the heating rate from room temperature to the set temperature was 5°C / min), and the titanium dioxide airgel was prepared. gel. The obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com