Reinforcing steel bar surface oxide skin densification treatment method and reinforcing steel bar surface oxide skin densification corrosion-resistant film

A technology of surface oxidation and treatment method, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as poor anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The embodiment of the present application provides a method for densification treatment of steel bar surface scale, which specifically includes:

[0066] 1. Tetraethyl silicate (TEOS), 3-epoxypropyloxypropyltrimethoxysilane (GPTMS), dehydrated alcohol and cerium nitrate solution were stirred at a constant temperature magnetic stirrer at 800r / min for 80min, using The acid-base regulator adjusts the pH value of the corrosion-resistant solution to 11 to obtain a corrosion-resistant solution; wherein, the mass ratio of TEOS:GPTMS is 1:0.29; Ce 3+ The mass ratio to Si is 1:0.11.

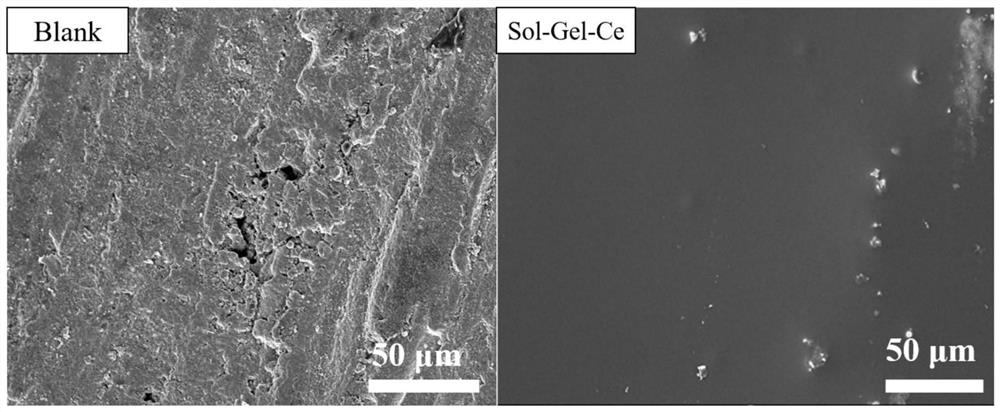

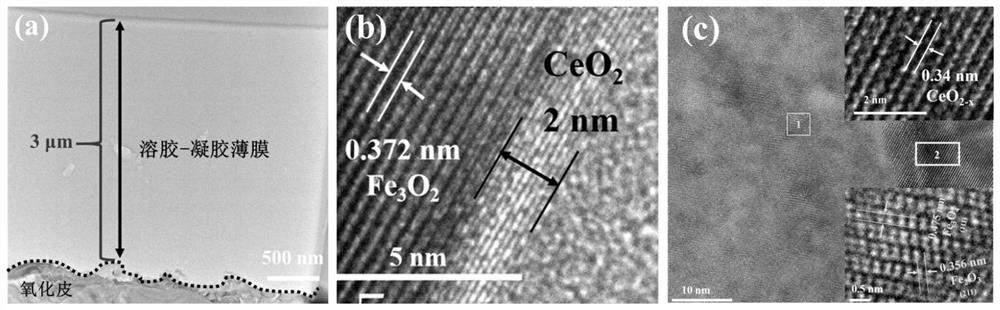

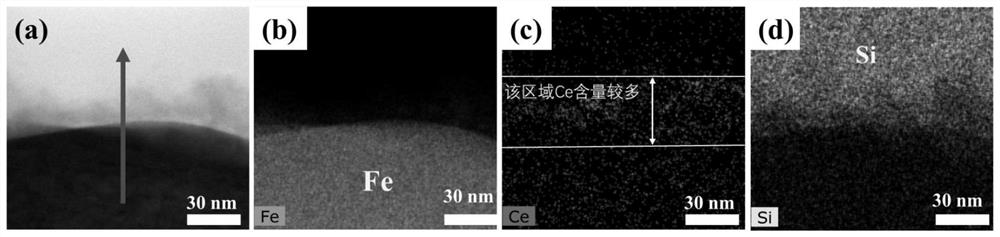

[0067] 2. Immerse the steel bar with oxide skin into the doped Ce prepared above at room temperature 3+ ionic corrosion-resistant solution, then take out the steel bar, put the steel bar in an oven and dry it at 200°C for 4 hours, and form a densified corrosion-resistant film on the surface of the steel bar with oxide skin, and obtain the treated steel bar, marked as Sol -Gel-Ce.

[0068] 3. Det...

Embodiment 2

[0077] The embodiment of the present application provides a method for densification treatment of steel bar surface scale, which specifically includes:

[0078] 1. Tetraethyl silicate (TEOS), 3-epoxypropyloxypropyltrimethoxysilane (GPTMS), dehydrated alcohol and cerium nitrate solution were stirred at a constant temperature magnetic stirrer at 800r / min for 80min, using The acid-base regulator adjusts the pH value of the corrosion-resistant solution to 11 to obtain a corrosion-resistant solution; wherein, the mass ratio of TEOS:GPTMS is 1:0.29; Ce 3+ The mass ratio to Si is 1:0.11.

[0079] 2. Immerse the steel bar with oxide skin into the doped Ce prepared above at room temperature 3+ Ionic corrosion-resistant solution, then take out the steel bar, put the steel bar in an oven and dry it at 200°C for 4 hours, and form a densified corrosion-resistant film on the surface of the steel bar with oxide skin to obtain the treated steel bar.

[0080] 3. Measure the morphology of the...

Embodiment 3

[0082] The embodiment of the present application provides a method for densification treatment of steel bar surface scale, which specifically includes:

[0083] 1. Tetraethyl silicate (TEOS), 3-epoxypropyloxypropyltrimethoxysilane (GPTMS), dehydrated alcohol and cerium nitrate solution were stirred at a constant temperature magnetic stirrer at 800r / min for 80min, using The acid-base regulator adjusts the pH value of the corrosion-resistant solution to 11 to obtain a corrosion-resistant solution; wherein, the mass ratio of TEOS:GPTMS is 1:0.29; Ce 3+ The mass ratio to Si is 1:0.11.

[0084] 2. Immerse the steel bar with oxide skin into the doped Ce prepared above at room temperature 3+ Ionic corrosion-resistant solution, then take out the steel bar, put the steel bar in an oven and dry it at 200°C for 4 hours, and form a densified corrosion-resistant film on the surface of the steel bar with oxide skin to obtain the treated steel bar.

[0085] 3. Measure the morphology of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com