Photovoltaic cell assembly and connection process thereof

A photovoltaic cell and cell technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of hidden cracks or desoldering, high cost, and difficult welding process of IBC cells, so as to reduce the risk of hidden cracks , low cost, and excellent power generation benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

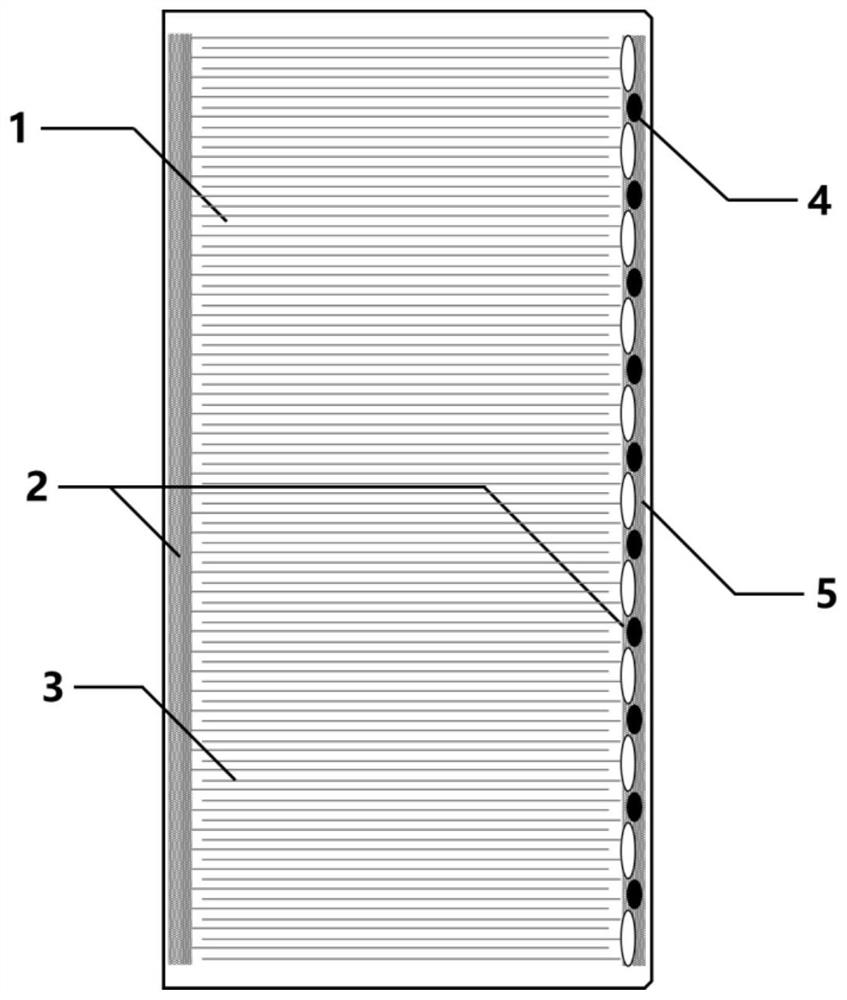

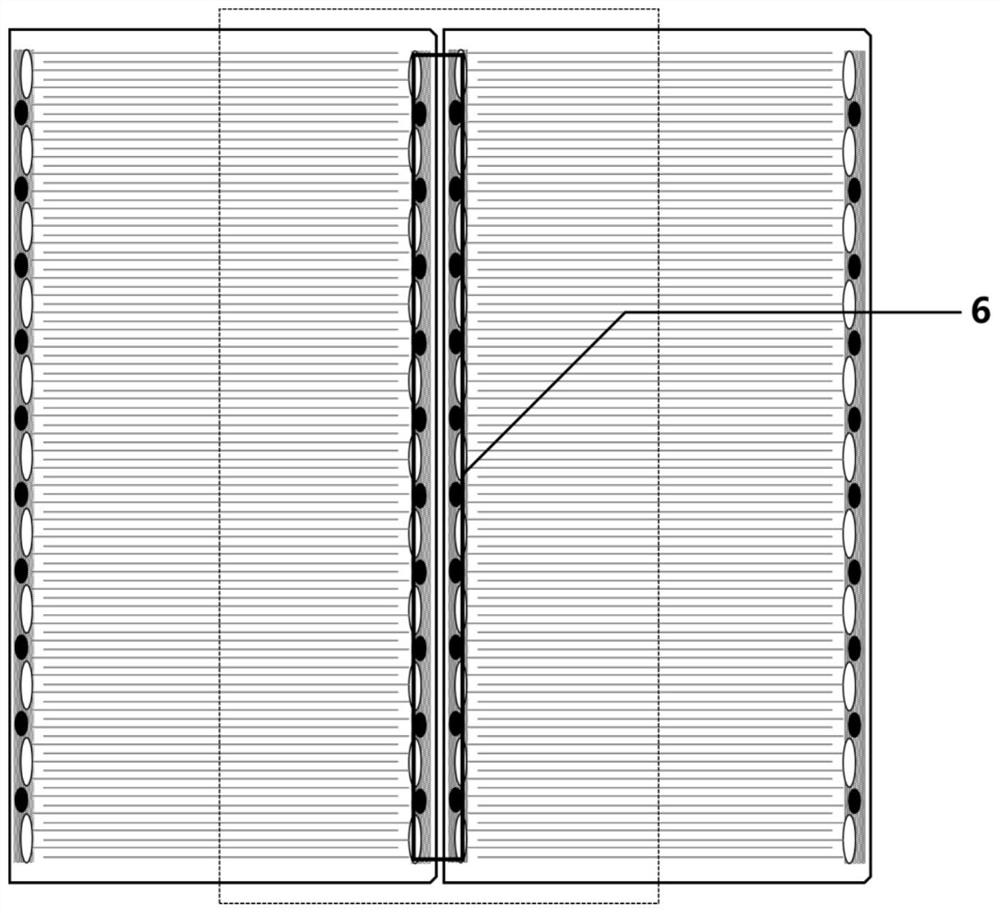

[0048] Such as Figure 1-2 As shown, a photovoltaic cell assembly, the cells 1 in the photovoltaic cell assembly are alternately arranged in parallel according to the positive and negative polarities, and the position between each two adjacent cells is placed along the long side of the cell 1 and welded. Ribbon 6, the spacing between two adjacent battery pieces 1 is -0.3~0.6mm, each welding ribbon 6 is bonded between two adjacent battery pieces 2, the main grid 2 of each battery piece 1 and the welding ribbon 6 Conductive glue 4 is selectively coated in the center of the overlapping area, and organic silica gel 5 is coated in the center of the overlapping area of each battery sheet 1 and the welding ribbon 6 or relatively close to the inner side of the battery sheet 1. The welding ribbon 6 is bonded and fixed to the two adjacent battery sheets 1, thereby realizing the connection between the two adjacent battery sheets 1, and the conductive adhesive 4 and the organic silica g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com