Ozone pressurized dissolved air tank and sewage advanced treatment system applied by ozone pressurized dissolved air tank

A pressurized gas-dissolving and advanced treatment technology, which is applied in the field of sewage treatment and water treatment systems, can solve the problems of low utilization rate, achieve the effect of improving the effect, increasing the contact time, and increasing the solubility of ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

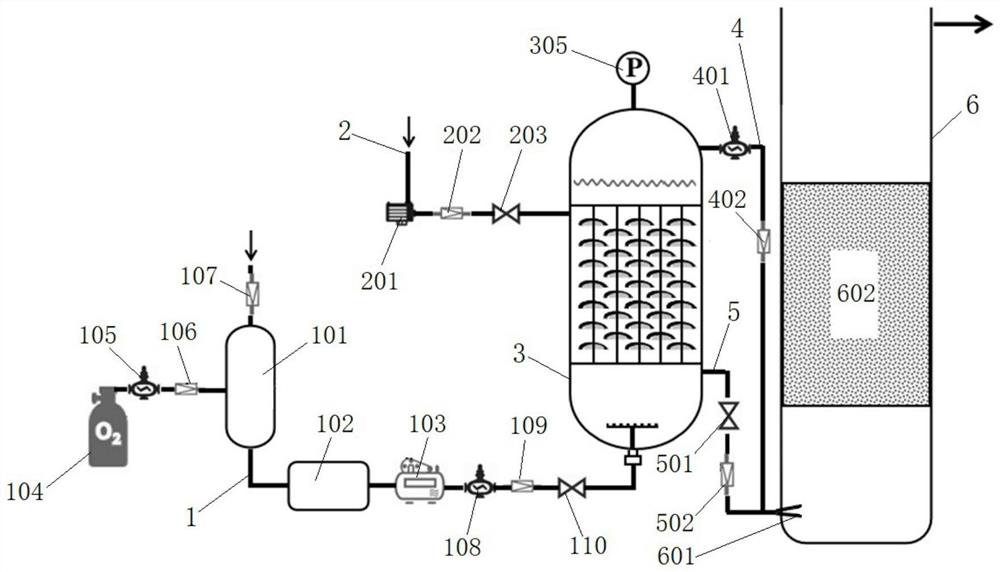

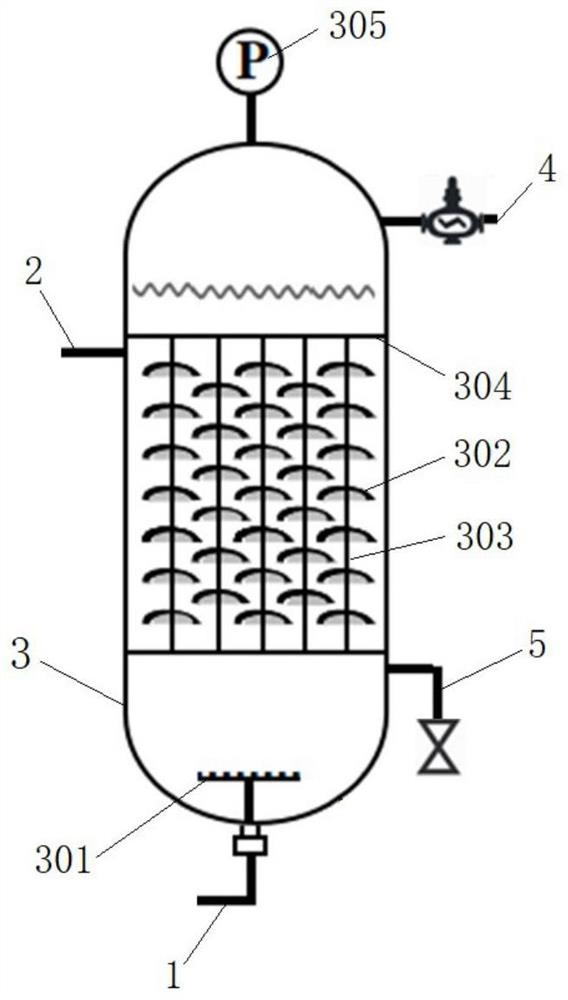

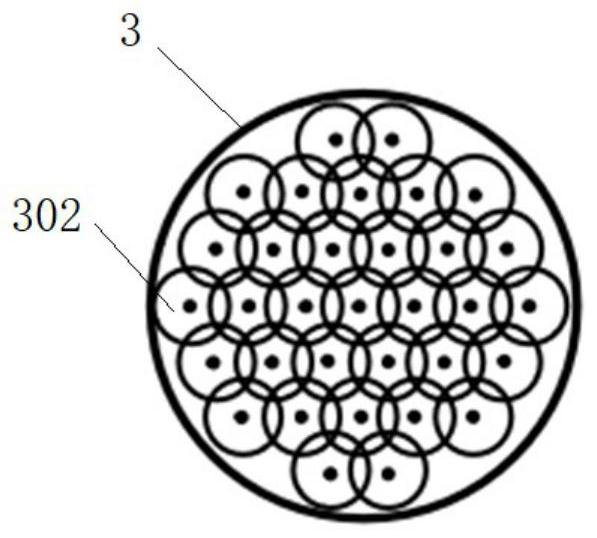

[0038] see figure 1, the sewage advanced treatment system in the illustration is a specific embodiment of the present invention, including an ozone inlet pipeline 1, a sewage water inlet pipeline 2, an ozone pressurized gas-dissolving tank 3, a gas release pipeline 4, and a liquid release pipeline 5 And ozone reaction tower 6, wherein ozone inlet line 1 is used to generate ozone gas and be transported in the ozone pressurized air-dissolving tank 3, it is connected with the air inlet of ozone pressurized air-dissolving tank 3, sewage water inlet pipeline 2 It is used to transport the preliminary treated sewage into the ozone pressurized dissolving tank 3, which is connected to the water inlet of the ozone pressurized dissolving tank 3. The ozone pressurized dissolving tank 3 has a pressure-sealed tank body to improve internal input The dissolution rate of the ozone gas in the sewage, the ozone pressurized gas dissolving tank 3 is connected with the water inlet of the ozone reac...

example 1

[0058] Use the ozone pressurized air-dissolving tank and sewage advanced treatment system in the above examples to treat the effluent of the papermaking wastewater secondary sedimentation tank, the inflow water is 1m3 / h, the temperature is 20°C, air V: oxygen V=1:1, ozone pressurized air-dissolving The pressure inside the tank is maintained at 0.3Mpa, the ozone concentration at the outlet of the ozone generator is 80mg / l, and the gas-water ratio is 30%. The residence time of sewage in the ozone pressurized dissolved air tank is 10min, the residence time of sewage in the ozone reaction tower is 30min, and the packing density of iron shavings is 300g / L. The COD of the raw water is 156mg / l, the COD of the effluent treated by the ozone pressurized air-dissolving tank is 88mg / l, and the COD of the effluent treated by the ozone reaction tower is 47mg / l.

example 2

[0060] Use the ozone pressurized air-dissolving tank and sewage advanced treatment system in the above example to treat the effluent of the pharmaceutical wastewater secondary sedimentation tank, the inflow water is 1m3 / h, the temperature is 20°C, air V: oxygen V=1:1.5, ozone pressurized air-dissolving The pressure inside the tank is maintained at 0.4Mpa, the ozone concentration at the outlet of the ozone generator is 100mg / l, and the gas-water ratio is 30%. The residence time of sewage in the ozone pressurized dissolved air tank is 15 minutes, the residence time of sewage in the ozone reaction tower is 30 minutes, and the packing density of iron shavings is 300g / L. The COD of the raw water is 146mg / l, the COD of the effluent treated by the ozone pressurized air-dissolving tank is 91mg / l, and the COD of the effluent treated by the ozone reaction tower is 53mg / l.

[0061] It can be seen that the COD in the secondary effluent treated by the ozone pressurized air-dissolving tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com