Preparation method of quartz ceramic rotary body

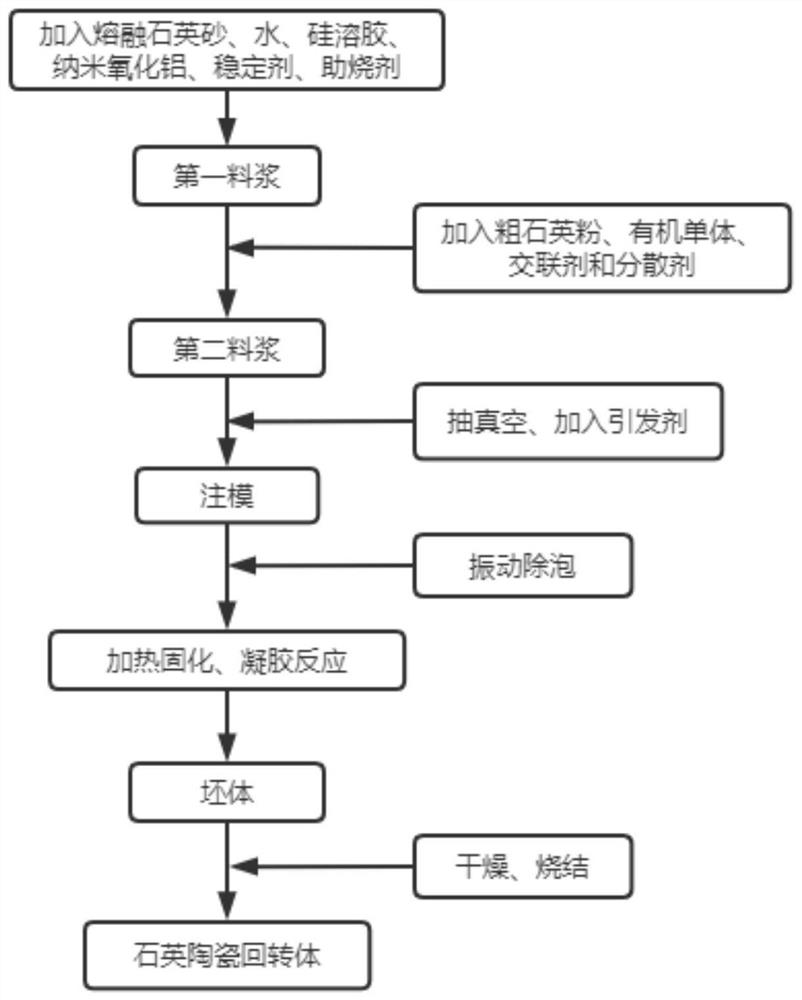

A quartz ceramic and rotary body technology is applied in the field of preparation of quartz ceramic rotary bodies, which can solve the problems of cracks, affecting product quality and service life, and large shrinkage of the green body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for preparing a quartz ceramic revolving body, comprising the following steps:

[0046] (1) Preparation of slurry

[0047] First mixing: Mix 36 parts of 50-mesh fused silica sand, 22 parts of pure water, 20 parts of silica sol, 7 parts of nano-alumina, 0.5 part of sintering aid, and 0.25 part of stabilizer, and then ball mill. As an optional solution, the material of the grinding balls is alumina balls, and the weight ratio of the alumina balls to the first slurry is (1-1.5):1. Preferably in this embodiment, the weight ratio of the alumina balls to the first slurry is 1:1. Alternatively, the sintering aid may be alkali metal lactate or alkali metal oxalate, and the stabilizer may be lactic acid or oxalic acid. Preferably in this embodiment, the sintering aid is sodium oxalate, and the stabilizer is oxalic acid. After ball milling for 30 hours, 68 parts of 50-mesh fused silica sand were added again, and ball milling was continued for ...

Embodiment 2

[0054] This embodiment provides a method for preparing a quartz ceramic revolving body, comprising the following steps:

[0055] (1) Preparation of slurry

[0056] First mixing: Mix 27 parts of 100-mesh fused silica sand, 18 parts of pure water, 12 parts of silica sol, 4 parts of nano-alumina, 0.2 part of sintering aid, and 0.1 part of stabilizer, and then ball mill. As an optional solution, the material of the grinding balls is alumina balls, and the weight ratio of the alumina balls to the first slurry is (1-1.5):1. Preferably in this embodiment, the weight ratio of alumina balls to the first slurry is 1.25:1. Alternatively, the sintering aid may be alkali metal lactate or alkali metal oxalate, and the stabilizer may be lactic acid or oxalic acid. Preferably in this embodiment, the sintering aid is sodium oxalate, and the stabilizer is oxalic acid. After ball milling for 20 hours, add 55 parts of 100-mesh fused silica sand again, and continue ball milling for 30 hours to ...

Embodiment 3

[0063] This embodiment provides a method for preparing a quartz ceramic revolving body, comprising the following steps:

[0064] (1) Preparation of slurry

[0065] First mixing: Mix 17 parts of 10-mesh fused silica sand, 15 parts of pure water, 5 parts of silica sol, 2 parts of nano-alumina, 0.01 part of sintering aid, and 0.02 part of stabilizer, and then ball mill. As an optional solution, the material of the grinding balls is alumina balls, and the weight ratio of the alumina balls to the first slurry is (1-1.5):1. Preferably in this embodiment, the weight ratio of the alumina balls to the first slurry is 1.5:1. Alternatively, the sintering aid may be alkali metal lactate or alkali metal oxalate, and the stabilizer may be lactic acid or oxalic acid. Preferably in this embodiment, the sintering aid is sodium oxalate, and the stabilizer is oxalic acid. After ball milling for 5 hours, add 42 parts of 10-mesh fused silica sand again, and continue ball milling for 8 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com