A kind of manufacturing method of 17crnimo6 forging

A manufacturing method and technology for forgings are applied in the field of manufacturing 17CrNiMo6 forgings, which can solve the problems of broken structure and large deformation, improve the tensile properties and elongation, control the depth of the carburized layer, and be beneficial to grain refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

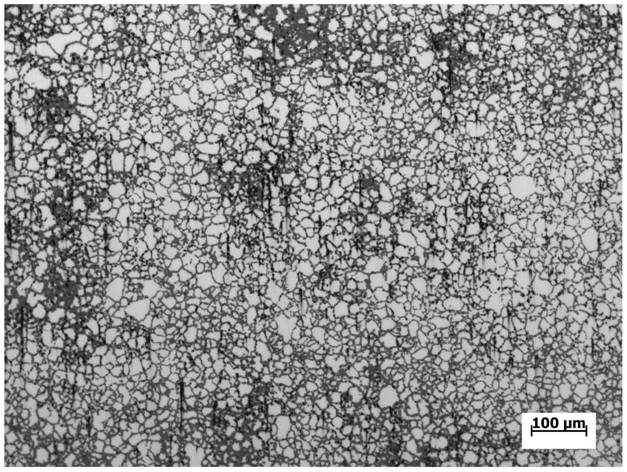

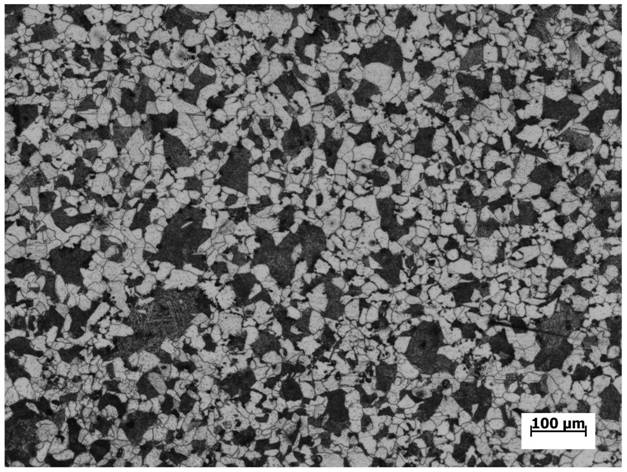

Image

Examples

Embodiment 1

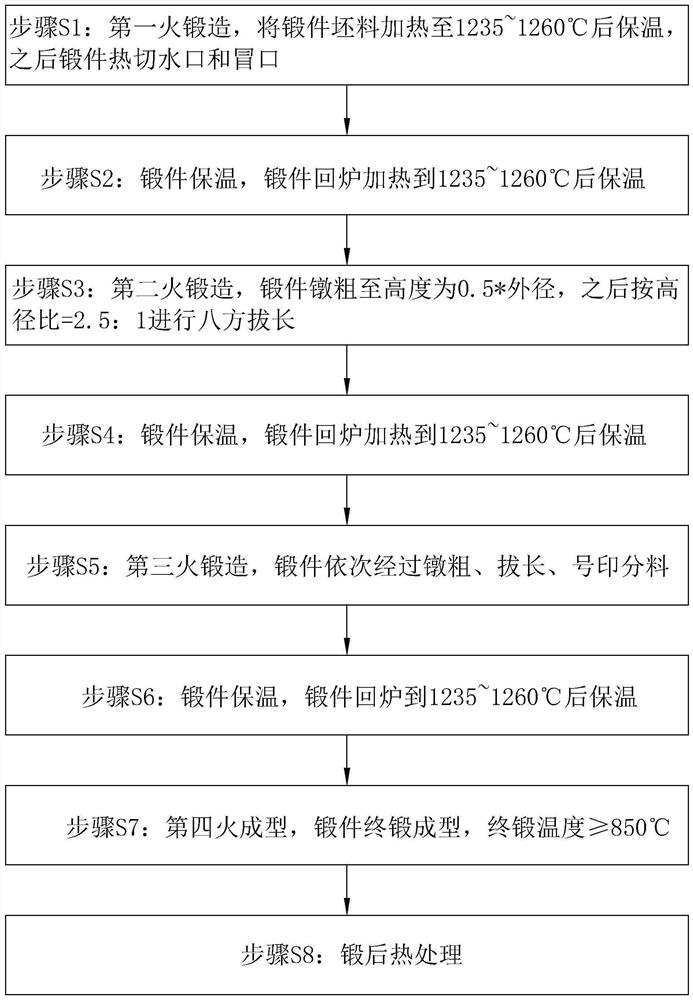

[0034] A manufacturing method of 17CrNiMo6 forging, such as figure 1 shown, including the following steps:

[0035] Before forging, prepare the alloy rough billet, including the composition by mass percentage: C: 0.14-0.19; Si: 0.15-0.35; Mn: 0.40-0.60; P≤0.025; S≤0.025; Cr: 1.50-1.80; Ni : 1.40-1.75; Mo: 0.25-0.35; Cu≤0.12; AI≤0.015; the balance is Fe.

[0036] Step S1: the first fire forging, heating the forging blank to 1250°C and holding it for 4 hours, then the forging is hot-cut to the nozzle and riser, the nozzle removal is not less than 4%, and the riser removal is not less than 14%.

[0037] Step S2: the forgings are kept warm, the forgings are heated to 1250°C after being returned to the furnace, and the heat preservation time is ≥5h.

[0038] Step S3: second fire forging, upsetting the forging to a height of 0.5*outer diameter, after the forging is upsetting to the specified height, the press is maintained for 2-3 minutes, and then the eight-way drawing is carried...

Embodiment 2

[0045] The steps different from Example 1 are:

[0046] Step S1: The first fire forging, heating the forging blank to 1237°C and holding the temperature for 5 hours, then the forging is hot-cut to the nozzle and riser, the nozzle removal is not less than 4%, and the riser removal is not less than 14%.

[0047] Step S2: the forgings are kept warm, and the forgings are heated to 1237°C after being returned to the furnace, and the heat preservation time is ≥5h.

[0048] Step S4: the forgings are kept warm, the forgings are heated to 1237°C after being returned to the furnace, and the heat preservation time is ≥10h.

[0049] Step S6: the forging is kept warm, and the forging is kept at 1237°C after being returned to the furnace, and the heat preservation time is less than or equal to 5h.

[0050]Step S8: post-forging heat treatment, the forgings are cooled to 330°C on the surface of the forgings, then enter the furnace, heat up to 400°C for 4 hours, continue to heat up to 650°C f...

Embodiment 3

[0052] The steps different from Example 1 are:

[0053] Step S1: The first fire forging, heating the forging blank to 1260°C and holding it for 5 hours, then hot cutting the nozzle and riser of the forging, the nozzle removal is not less than 4%, and the riser removal is not less than 14%.

[0054] Step S2: the forgings are kept warm, the forgings are heated to 1260° C. and then kept warm for a holding time of ≥5h.

[0055] Step S4: the forgings are kept warm, the forgings are heated to 1260°C after being returned to the furnace, and the heat preservation time is ≥10h.

[0056] Step S6: the forging is kept warm, the forging is kept at 1260°C after being returned to the furnace, and the heat preservation time is less than or equal to 5h.

[0057] Step S8: post-forging heat treatment, the forgings are cooled to 340°C on the surface of the forgings, then enter the furnace, heat up to 420°C for 5 hours, continue to heat up to 670°C for 6 hours, continue to heat up to 970°C for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com