Application of highland barley cooked powder in improving quality of highland barley bread, highland barley bread and preparation method of highland barley bread

A technology of highland barley flour and highland barley, which is applied to the application of cooked highland barley flour in improving the quality of highland barley bread, and the field of highland barley bread and its preparation. Effects of dough quality, gut protection, low glycemic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention has no special requirements on the source of the highland barley powder, and it can be purchased by those skilled in the art, or can be prepared by oneself. When self-prepared, the preparation method of the highland barley powder preferably includes the following steps: the highland barley powder is sequentially pretreated and crushed to obtain the highland barley powder.

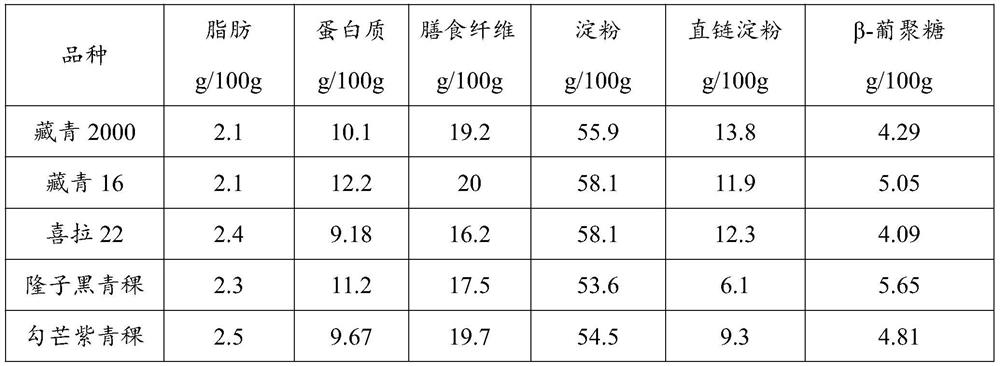

[0039] In the present invention, the highland barley is preferably highland barley with bran, which can increase the dietary fiber and nutrition in highland barley powder; the highland barley variety is preferably Tibetan green 2000. The amylose content of the highland barley variety adopted in the invention is relatively high, which ensures that more resistant starch can be obtained after autoclaving. In the present invention, the pretreatment includes screening, removing impurities, washing and drying. The present invention has no limitation on the methods of screening, impur...

Embodiment 1

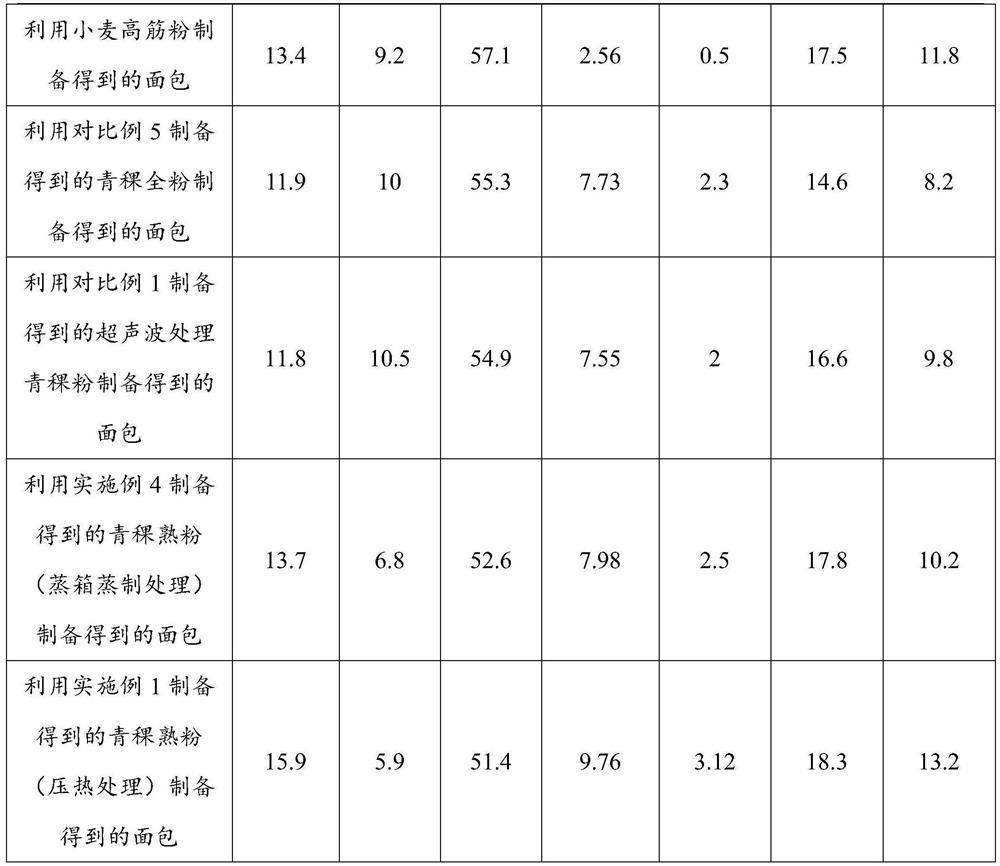

[0086] Highland barley bread formula: 30 parts (30g) of cooked highland barley flour, 270 parts (270g) of high-gluten wheat flour, 3 parts (3g) of yeast, 23 parts (23g) of xylitol, 35 parts (35g) of butter, 45 parts of eggs ( 1 piece, 45g), 2 parts (2g) of bread improver, 1.5 parts (1.5g) of aluminum-free leavening agent, 0.1 part (0.1g) of milk powder, 12 parts (12g) of milk powder, 1 part (1g) of salt , 200 parts (200g) of water.

[0087] The preparation method of cooked highland barley powder:

[0088] Highland barley (Tibetan Green 2000) is screened, impurity removed, washed, dried (with a water content of 12wt.% to 14wt.%), then ground into powder and passed through an 80-mesh sieve to obtain highland barley powder;

[0089] Weigh highland barley flour, water and a thin batter with a starch milk concentration of 25%, put it in a water bath, heat it in a water bath at 65°C for 30 minutes, and then put it in an autoclave at 121°C and a pressure of 0.1 to 0.15Mpa. Gelatini...

Embodiment 2

[0098] Highland barley bread formula: 115 parts (115g) of cooked highland barley flour, 185 parts (185g) of high-gluten wheat flour, 6 parts (6g) of gluten powder, 4 parts (4g) of yeast, 25 parts (25g) of xylitol, 45 parts of butter 45 parts (45g), 45 parts (1 piece, 45g) of eggs, 2.5 parts (2.5g) of bread improver, 3 parts (3.0g) of aluminum-free leavening agent, 0.4 parts (0.4g) of milk powder, 23 parts of milk powder (23g), 1.5 parts (1.5g) of salt, 210 parts (210g) of water.

[0099] The preparation method of cooked highland barley flour and highland barley bread is the same as in Example 1, wherein gluten is mixed with cooked highland barley flour, wheat high-gluten flour, yeast, bread improver, aluminum-free leavening agent, milk flavor powder, and milk powder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com