Active scaffold for multi-cell printing and nervating bone regeneration as well as preparation method and application of active scaffold

A bone regeneration and multicellular technology, which is applied in manufacturing, prosthesis, additive processing, etc., can solve the problems of poor bone regeneration and neglect of the important role of the nervous system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation of bio-ink: first prepare the concentrated solution of bone marrow mesenchymal stem cells, and then mix it uniformly with the above-mentioned hydrogel slurry to obtain bio-ink A with a cell density of 3,000,000 cells / mL. Similarly, the concentrated solution of Schwann cells was prepared, and then evenly mixed with the above-mentioned hydrogel slurry to obtain bioink B with a cell density of 3,000,000 cells / mL.

[0056] Printing process: Bio-inks A and B were printed using two pneumatic extrusion needles 1 and 2, respectively. First use needle 1 to extrude bio-ink A to print several layers as the lower layer, then use needle 2 to extrude bio-ink B to print several layers as the upper layer, the ratio of the number of upper and lower layers is 5:1-1:5, more preferably 1:1. In addition, the pressure of the two extrusion needles is 20-100 Kpa, the temperature of the extrusion needles is controlled at 18-22°C, and the temperature of the deposition table is contro...

Embodiment 1

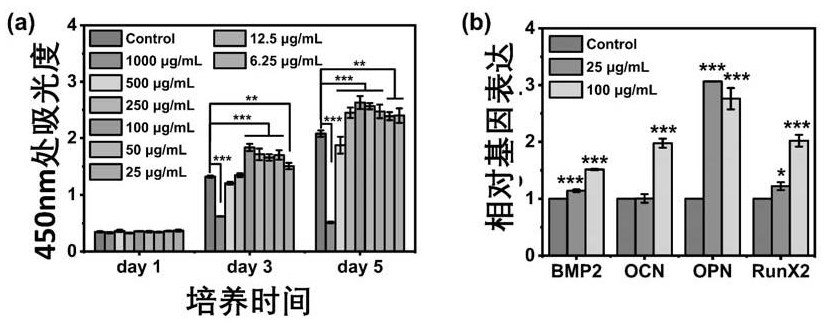

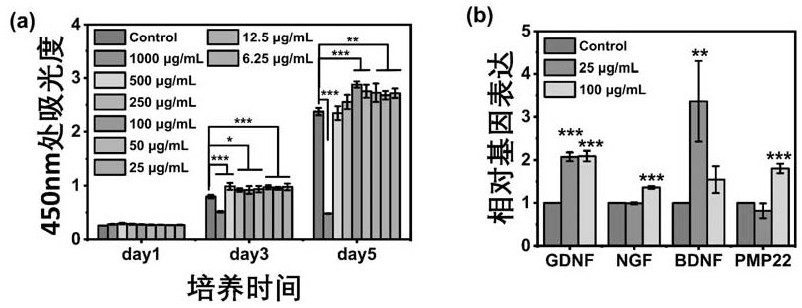

[0060] Effects of calcium silicate nanowires on the proliferation, migration and differentiation of bone marrow mesenchymal stem cells and Schwann cells:

[0061] Firstly, calcium silicate nanowires were prepared by hydrothermal method, and 9.446g of Ca(NO 3 ) 2 4H 2 O and 11.368 g of Na 2 SiO 3 9H 2 O was dissolved in 100 mL of deionized water, and magnetically stirred until completely dissolved. Na 2 SiO 3 9H 2 O solution was poured into Ca(NO 3 ) 2 4H 2 In the O solution, magnetically stir for 1 hour to form a uniformly dispersed white suspension; then put it into a hydrothermal kettle for 24 hours of hydrothermal reaction at 200 ° C, after cooling, filter it with suction and wash it thoroughly, you can get a good shape calcium silicate nanowires.

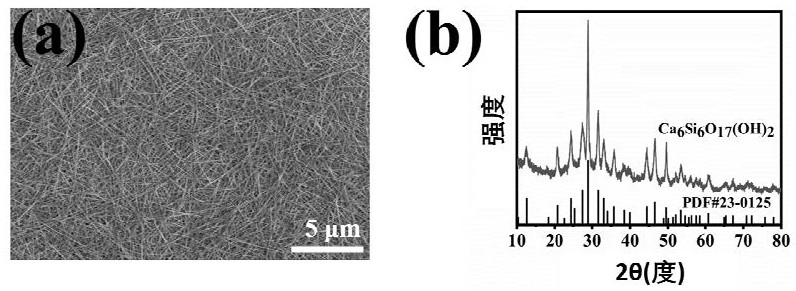

[0062] figure 1 The scanning electron microscope and X-ray diffraction results of the calcium silicate nanowires prepared according to the above method indicate that the calcium silicate nanowire material has been s...

Embodiment 2

[0072] Preparation and characterization of composite hydrogel scaffolds with gradient concentrations of calcium silicate nanowires: firstly, hydrogel slurries containing different calcium silicate nanowire contents were prepared. First weigh 0.025g of LAP photoinitiator and dissolve it in 10mL of deionized water, then add 0.6g of methacrylated gelatin, fully dissolve at 60°C to obtain a 6wt% methacrylated gelatin solution. After drawing 3mL of methacrylylated gelatin solution and mixing evenly with 0.0036g of calcium silicate nanowires, a hydrogel slurry containing 2% calcium silicate nanowires can be obtained; similarly, drawing 3mL of methacrylic After uniformly mixing the acylated gelatin solution with 0.0072 g of calcium silicate nanowires, a hydrogel slurry containing 4% calcium silicate nanowires can be obtained.

[0073] The effect of incorporation of different contents of calcium silicate nanowires on the rheological properties of methacrylated gelatin hydrogels was fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com