Isocyanate microcapsule and preparation method thereof

A kind of isocyanate, microcapsule technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

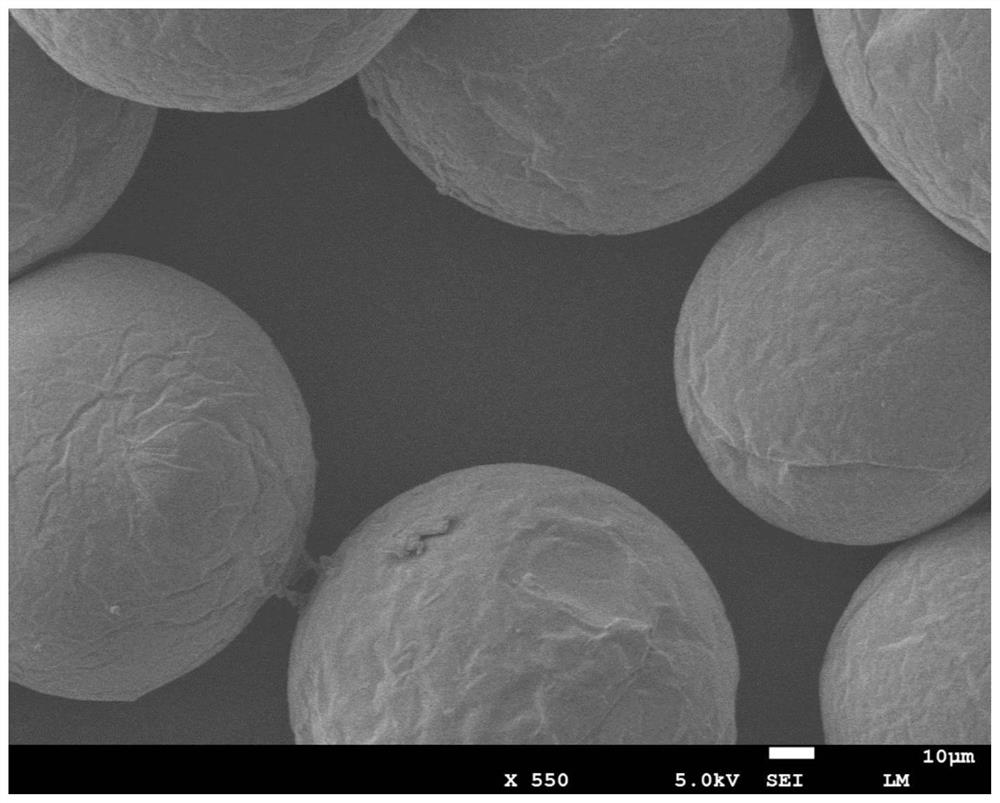

Image

Examples

Embodiment 1

[0037] A kind of isocyanate microcapsule, it is characterized in that, with isocyanate as microcore, with low melting point organic matter as capsule wall coating described microcore, described isocyanate microcapsule comprises the raw material component of following mass percentage:

[0038] 67% dispersion medium, 12% low-melting organic matter, 2% emulsifier, 18% isocyanate, 1% acid stabilizer.

[0039] Wherein, the dispersion medium is water; the low-melting point organic matter is stearic acid; the emulsifier is sodium carboxymethyl cellulose; the isocyanate is polymethylene polyphenyl polyisocyanate (PAPI); the acid stabilizer is hydrochloric acid.

[0040] The concrete preparation method of isocyanate microcapsule is as follows:

[0041] (1) Stearic acid is heated to melt at 72°C, then polymethylene polyphenyl polyisocyanate is added and mixed uniformly to obtain a dispersed phase;

[0042] (2) Mix sodium carboxymethylcellulose, hydrochloric acid, and water evenly, and ...

Embodiment 2

[0047] A kind of isocyanate microcapsule, it is characterized in that, with isocyanate as microcore, with low melting point organic matter as capsule wall coating described microcore, described isocyanate microcapsule comprises the raw material component of following mass percentage:

[0048] 60% dispersion medium, 12% low melting point organic matter, 2% emulsifier, 25% isocyanate, 1% acid stabilizer.

[0049] Among them, the dispersion medium is simethicone; the low-melting organic matter is solid wax; the emulsifier is sodium lauryl sulfate; the isocyanate is toluene-2,4-diisocyanate; the acid stabilizer is formic acid.

[0050] The concrete preparation method of isocyanate microcapsule is as follows:

[0051] (1) Heat the solid wax at 70°C to melt, then add toluene-2,4-diisocyanate and mix evenly to obtain a dispersed phase;

[0052] (2) Mix sodium lauryl sulfate, formic acid, and simethicone evenly, and heat to 70°C to obtain a continuous phase;

[0053] (3) Add the above...

Embodiment 3

[0056] A kind of isocyanate microcapsule, it is characterized in that, with isocyanate as microcore, with low melting point organic matter as capsule wall coating described microcore, described isocyanate microcapsule comprises the raw material component of following mass percentage:

[0057] 60% dispersion medium, 12% low melting point organic matter, 2% emulsifier, 25% isocyanate, 1% acid stabilizer.

[0058] Among them, the dispersion medium is liquid paraffin; the low melting point organic matter is stearyl alcohol; the emulsifier is castor oil polyoxyethylene ether; the isocyanate is polymethylene polyphenyl polyisocyanate; and the acid stabilizer is phosphoric acid.

[0059] The concrete preparation method of isocyanate microcapsule is as follows:

[0060] (1) Heating stearyl alcohol at 60°C to melt, then adding polymethylene polyphenyl polyisocyanate and mixing evenly to obtain a dispersed phase;

[0061] (2) Mix polymethylene polyphenyl polyisocyanate, phosphoric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com