Barium titanate nano array and preparation method thereof

A nano-array and barium titanate technology, applied in the field of materials, can solve the problems that are not suitable for the increasingly miniaturized characteristics of electronic devices, and achieve the effect of improving the photoelectric response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

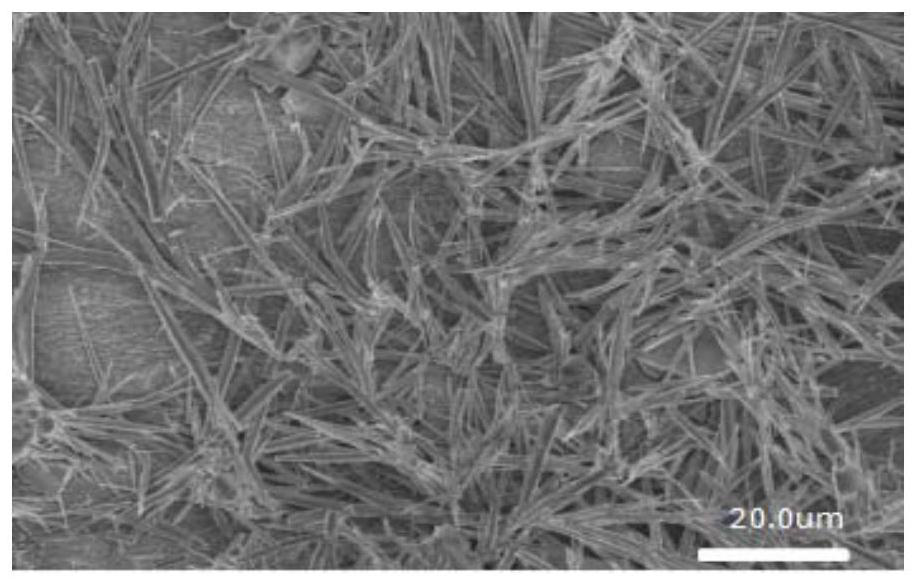

[0026] The invention provides a method for preparing a barium titanate nanoarray, comprising:

[0027] A) Titanium dioxide foil and sodium hydroxide are subjected to hydrothermal reaction to obtain an intermediate product;

[0028] B) Mix the intermediate product with barium hydroxide and react to obtain barium titanate nano-arrays.

[0029] The preparation method of the barium titanate nano-array provided by the present invention first prepares the titanium dioxide foil.

[0030] The preparation method of the titanium dioxide foil of the present invention is specifically: the titanium foil is ultrasonically cleaned with absolute ethanol, acetone and deionized water in sequence, and then reacted to obtain the titanium dioxide foil.

[0031] Firstly, a titanium foil with a size of 1.5-2.0cm*3.0-3.5cm is selected.

[0032] Then use anhydrous ethanol, acetone and deionized water in order to clean them in ultrasonic for 10-20 minutes respectively to obtain a clean foil.

[0033...

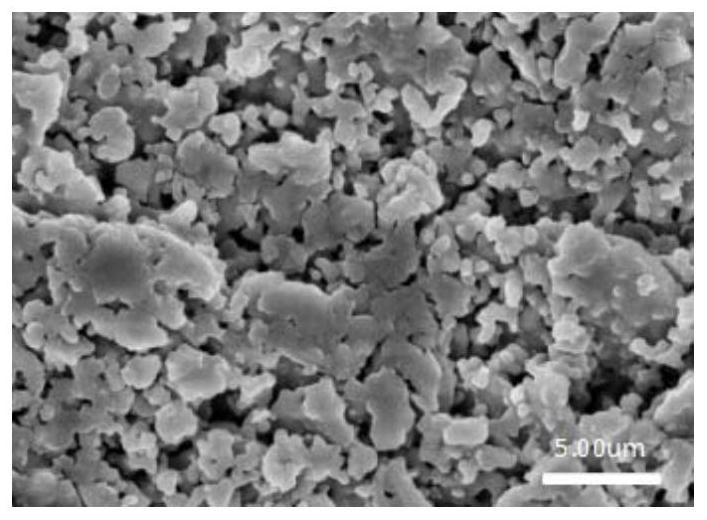

Embodiment 1

[0053]Put the titanium dioxide foil into the inner lining of polytetrafluoroethylene, add 12mol / L sodium hydroxide solution, put it into the reaction kettle for packaging, put the reaction kettle into the drying oven, and react at 210°C for 4 to 12 hours respectively , to obtain products under different concentrations of sodium hydroxide and different reaction times, and use ultrasonic to clean the obtained samples with deionized water and absolute ethanol, and then perform the second step of hydrothermal. Put the sample into the inner liner of polytetrafluoroethylene, add saturated barium hydroxide solution, put it into the reaction kettle and seal it, then put the reaction kettle into the drying oven, react at 210 ° C for 12 hours, and the obtained sample is deionized Ultrasonic cleaning with water and absolute ethanol can grow barium titanate nano-arrays on the titanium dioxide base.

[0054] The result is as Image 6 as shown, Image 6 It is a graph showing the photoelec...

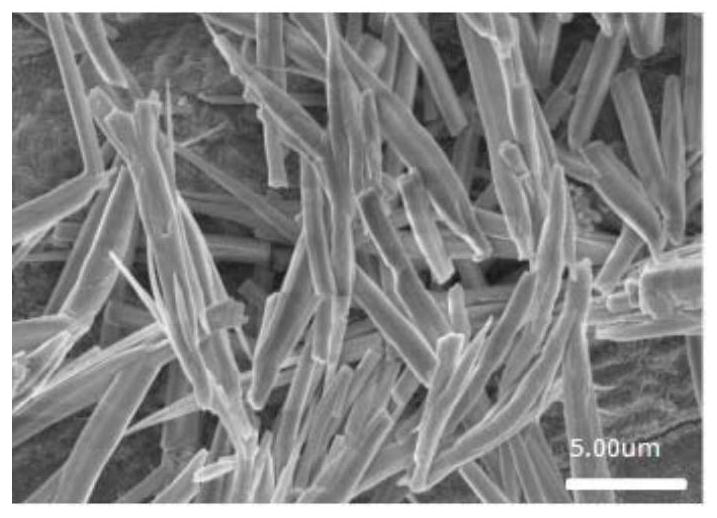

Embodiment 2

[0058] Put the titanium dioxide foil into the inner lining of polytetrafluoroethylene, add 11mol / L sodium hydroxide solution, put it into the reaction kettle for packaging, put the reaction kettle into the drying oven, and react at 210°C for 4 to 12 hours respectively , to obtain products under different concentrations of sodium hydroxide and different reaction times, and use ultrasonic to clean the obtained samples with deionized water and absolute ethanol, and then perform the second step of hydrothermal. Put the sample into the lining of polytetrafluoroethylene, add saturated barium chloride solution, put it into the reaction kettle and seal it, then put the reaction kettle into the drying oven, react at 200°C for 14h, and the obtained sample is deionized Ultrasonic cleaning with water and absolute ethanol can grow barium titanate nano-arrays on the titanium dioxide base.

[0059] The result is as Figure 5 as shown, Figure 5 It is a photoelectric performance result grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com