Air coupling ultrasonic transducer for non-contact detection of insulation defects of switch cabinet

An ultrasonic transducer, air-coupling technology, applied in the field of acoustic transducers, can solve the problems of low efficiency of air-coupled ultrasonic transducers, large differences in acoustic impedance, fast ultrasonic attenuation, etc., to improve sensitivity and frequency bandwidth characteristics , The signal rises quickly, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The embodiment of the present disclosure introduces an air-coupled ultrasonic transducer for non-contact detection of insulation defects of switch cabinets.

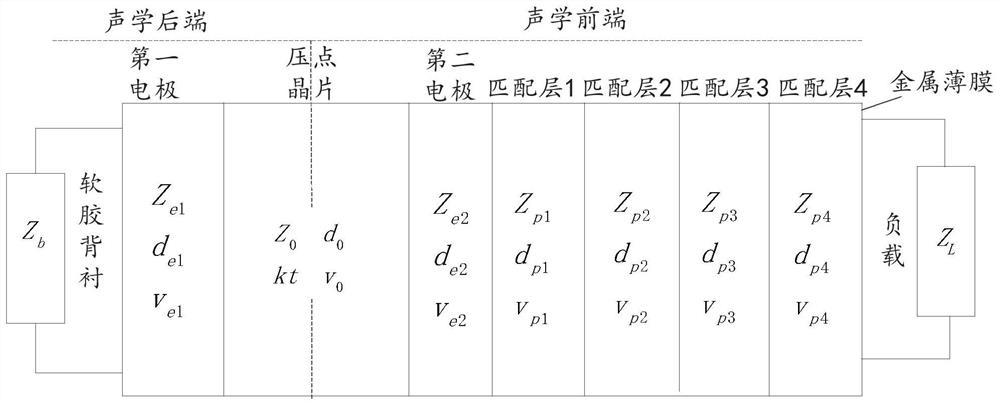

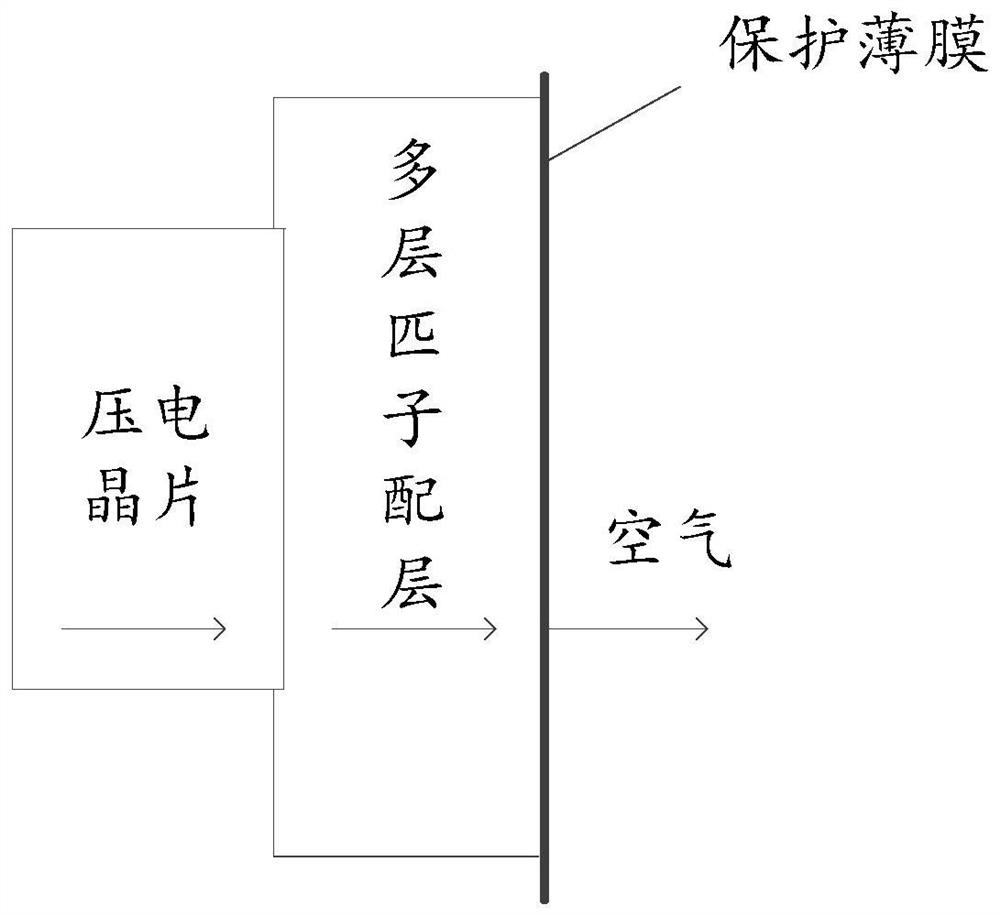

[0032] In order to improve the sensitivity of the air-coupled ultrasonic transducer, this embodiment introduces a new type of air-coupled ultrasonic transducer. In air-coupled ultrasonic transducers, piezoelectric wafers are the core components of the entire transducer. In order to realize the acoustic impedance transition, this embodiment properly designs the number of matching layers, and designs an air coupler with four matching sub-layers.

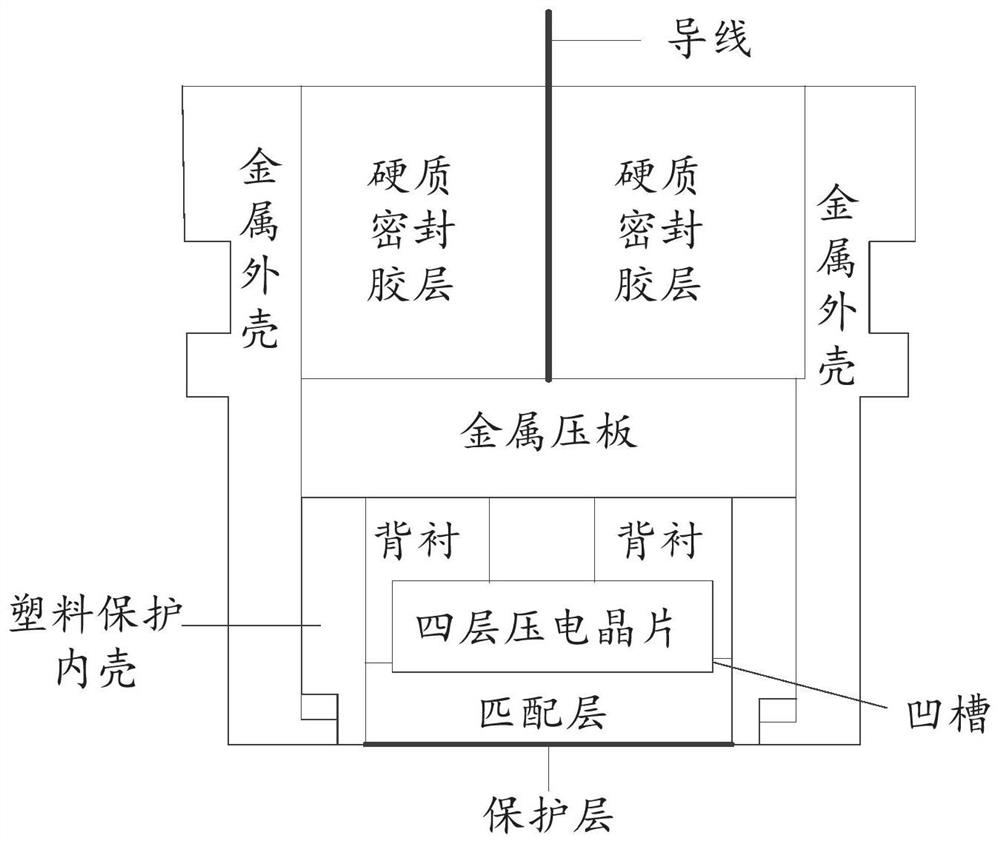

[0033] Such as figure 1 The shown air-coupled ultrasonic transducer (referred to as the transducer for short) for the non-contact detection of insulation defects in switchgear adopts a cylindrical structure, including a coaxial hard sealant layer arranged from the inside to the outside. , metal pressure plate, soft rubber backing, piezoelectric chip and matching layer; t...

Embodiment 2

[0040] This embodiment introduces an air-coupled ultrasonic transducer matching system for non-contact detection of switchgear insulation defects, using the air-coupled ultrasonic transducer introduced in the embodiment for non-contact detection of switchgear insulation defects transducer.

[0041] Such as Figure 4 An air-coupled ultrasonic transducer matching system for non-contact detection of switchgear insulation defects is shown, including a matching circuit, a signal acquisition module and an air-coupled ultrasonic transducer; the ultrasonic signal is transmitted to the air-coupled ultrasonic transducer through the matching circuit In the transducer, the impedance signal of the transducer collected in real time is fed back to the matching circuit through the signal acquisition module.

[0042] The external temperature, load and other factors will have a certain impact on the impedance and frequency characteristics of the transducer, which may cause impedance mismatch. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com