Transducer based on 2-2 type piezoelectric composite material covering matching layer and preparation method thereof

A piezoelectric composite material and composite material technology are applied in the field of transducers based on 2-2 type piezoelectric composite materials covering matching layers and their preparation, and can solve problems such as difficult sensitivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

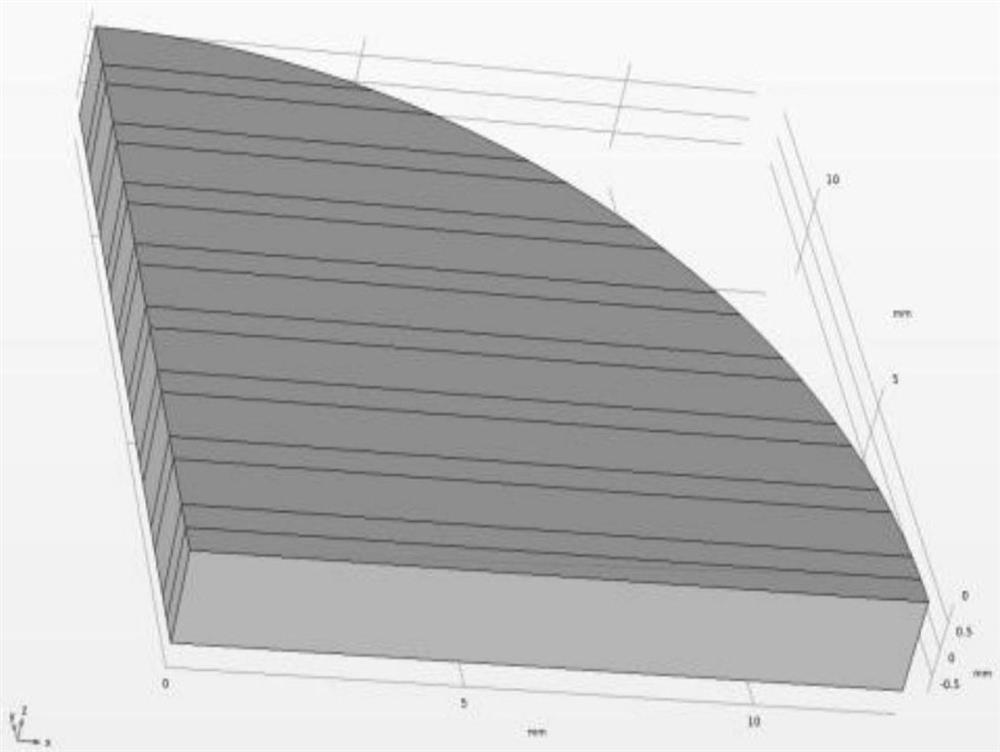

[0023] refer to figure 2 , image 3 As shown, the present invention widens the bandwidth of the high-frequency transducer, selects different polymer phase widths for the piezoelectric material sensitive element, and makes the transducer by covering the surface of the piezoelectric composite material with a matching layer to achieve the maximum frequency bandwidth expand.

[0024] This embodiment provides a method for preparing a transducer based on a 2-2 type piezoelectric composite covering a matching layer, including

[0025] Step S1: cutting the piezoelectric phase, pouring an epoxy polymer phase on the surface of the cut piezoelectric phase and polishing it, then plating electrodes, and welding leads on the electrodes to form a 2-2 type composite material;

[0026] Step S2: Pouring a matching layer on the radiating surface of the 2-2 composite material, and pasting an acoustic backing on the non-radiating surface of the 2-2 composite material to obtain a vibrator; in th...

Embodiment 2

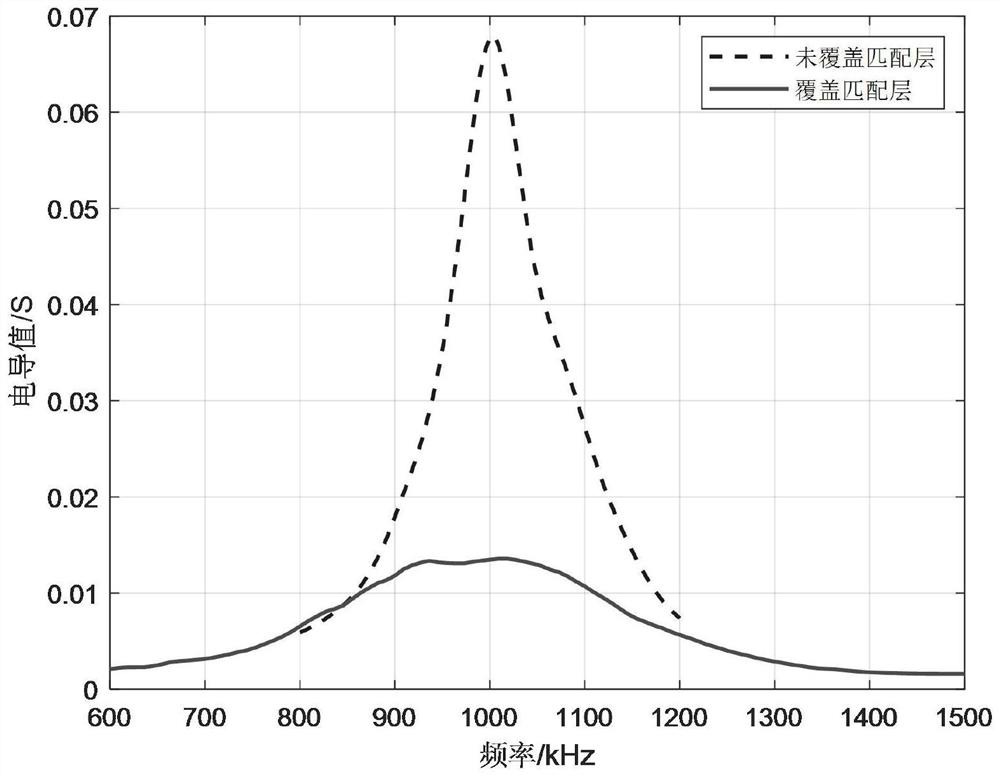

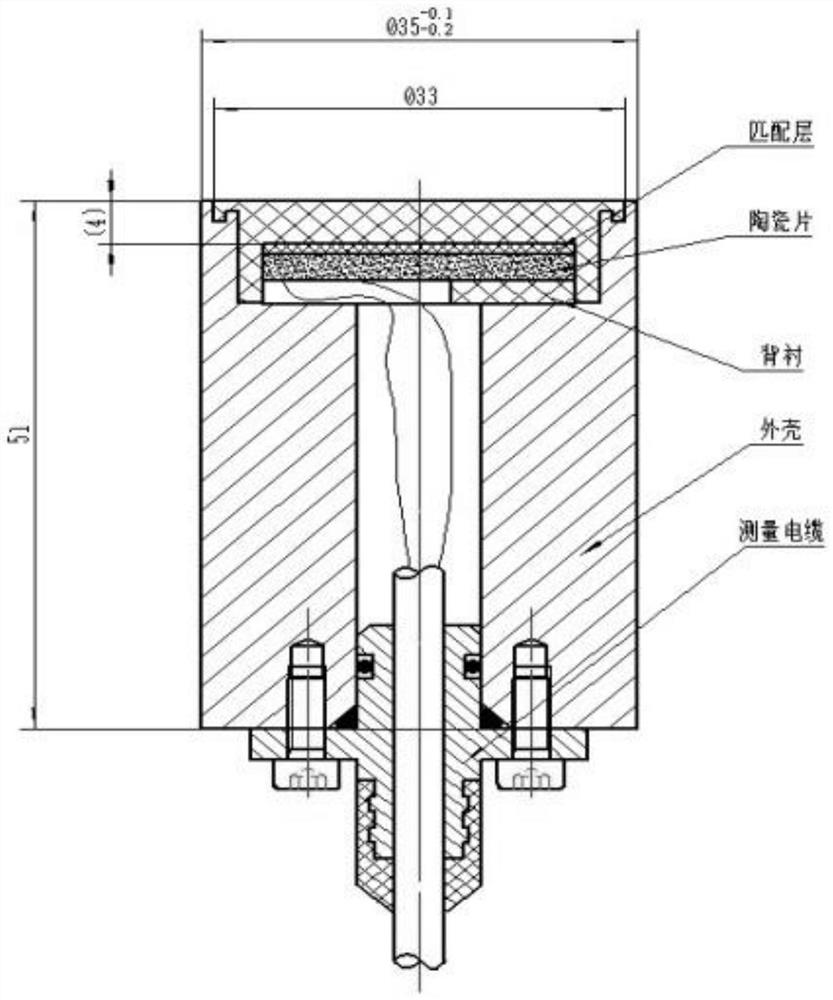

[0029] A vibrator with a resonant frequency close to 1MHz and a matching layer is made into a transducer. First, 25mm*2.5mm glass beads are pasted on the non-radiating surface of the vibrator as a backing, and fixed in a cylindrical metal shell with double-sided adhesive. The diameter of the metal shell is 34mm, the outer height is 50mm, and the inner height is 10mm, ensuring that the thickness of the polyurethane sound-permeable layer poured on the radiating surface is close to 4mm; the effect of the covering matching layer on the bandwidth of the transducer is studied by testing the conductance in water, sending voltage response and sensitivity response curve influences. figure 1 , Figure 4 , Figure 5 The result curve shows that when the thickness of the matching layer is selected as 0.61mm (ie 1 / 4 wavelength), the transducer's transmission voltage response -3dB achieves good coupling, its bandwidth can reach 400kHz, and the fluctuation of the transmission voltage respons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com