Process for green preparation of molybdenum powder by ammonia gas and hydrogen relay reduction of ammonium molybdate

A green technology of ammonium molybdate, which is applied in the field of green preparation of molybdenum powder by the relay reduction of ammonium molybdate with ammonia and hydrogen, can solve the problem of reducing the efficiency of gas-solid reduction and product yield, and cannot realize the relay of ammonia and hydrogen Reduction process, increasing NH and other issues, to achieve the effects of less adsorption and storage of other impurities, reduced hydrogen consumption, and good surface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

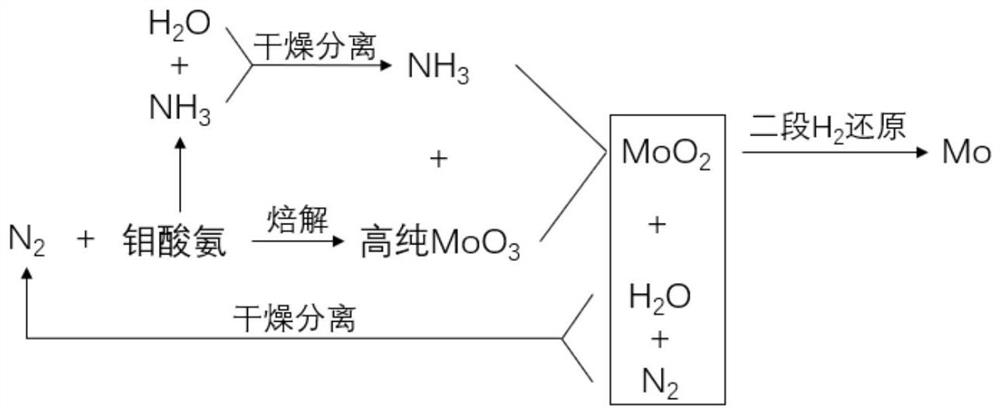

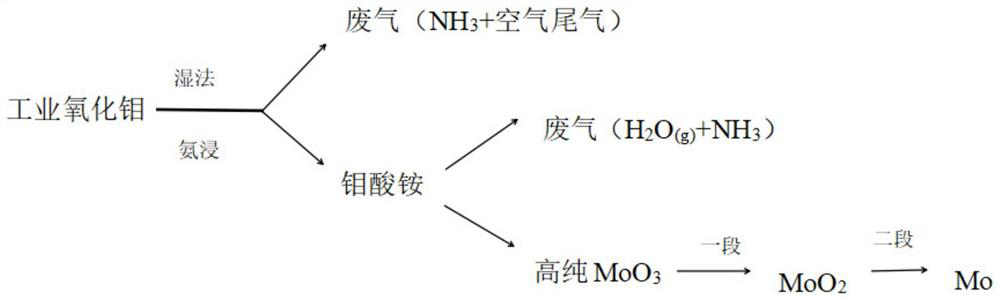

[0052] A green process for preparing molybdenum powder through the relay reduction of ammonium molybdate by ammonia and hydrogen, comprising the following steps:

[0053] (1) Ammonium molybdate is carried out roasting treatment in the atmosphere of nitrogen, the temperature of roasting is 540 ℃, the roasting time is 2.2h, generates molybdenum trioxide, ammonia gas and steam, and the ammonia gas and water vapor that produce Water vapor is dried and separated, ammonia and water vapor are dried and separated, and then the water vapor is removed by bottom blowing air supply to obtain dry ammonia;

[0054] (2) Reducing molybdenum trioxide with dry ammonia to generate molybdenum dioxide, water vapor and nitrogen, the molar ratio of ammonia to molybdenum trioxide is 2:3, and the reduction temperature is 400°C;

[0055] (3) Molybdenum dioxide is reduced with hydrogen, the molar ratio of hydrogen to molybdenum dioxide is 2.5:1, and the temperature is 850°C to obtain molybdenum powder. ...

Embodiment 2

[0057] A green process for preparing molybdenum powder through the relay reduction of ammonium molybdate by ammonia and hydrogen, comprising the following steps:

[0058] (1) Ammonium molybdate is carried out roasting treatment in the atmosphere of nitrogen gas, the temperature of roasting is 545 ℃, and roasting time is 2.1h, generates molybdenum trioxide, ammonia gas and steam, and the ammonia gas and water vapor that produce Water vapor is dried and separated, ammonia and water vapor are dried and separated, and then the water vapor is removed by bottom blowing air supply to obtain dry ammonia;

[0059] (2) Reducing molybdenum trioxide with dry ammonia gas to generate molybdenum dioxide, water vapor and nitrogen, the molar ratio of ammonia gas to molybdenum trioxide is 1:1, and the reduction temperature is 450°C;

[0060] (3) Molybdenum dioxide is reduced with hydrogen, the molar ratio of hydrogen to molybdenum dioxide is 2.4:1, and the temperature is 900°C to obtain molybde...

Embodiment 3

[0062] A green process for preparing molybdenum powder through the relay reduction of ammonium molybdate by ammonia and hydrogen, comprising the following steps:

[0063] (1) Ammonium molybdate is carried out roasting treatment in the atmosphere of nitrogen, the temperature of roasting is 550 ℃, and roasting time is 2h, generates molybdenum trioxide, ammonia gas and steam, and the ammonia gas and water that produce Steam is dried and separated, ammonia and water vapor are dried and separated, and then the water vapor is removed by bottom blowing air supply to obtain dry ammonia;

[0064] (2) Reducing molybdenum trioxide with dry ammonia to generate molybdenum dioxide, water vapor and nitrogen, the molar ratio of ammonia to molybdenum trioxide is 4:3, and the reduction temperature is 525°C;

[0065] (3) Using hydrogen to reduce molybdenum dioxide, the molar ratio of hydrogen to molybdenum dioxide is 2.25:1, and the temperature is 950°C to obtain molybdenum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com