Ammonia gas plant deodorant and preparation method and application thereof

A deodorant and plant technology, applied in the field of ammonia plant deodorant and its preparation, can solve the problems of large consumption of chemical agents, complex culture conditions, frequent replacement, etc., achieve excellent photocatalytic activity, efficiently remove ammonia, The effect of reducing ammonia pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

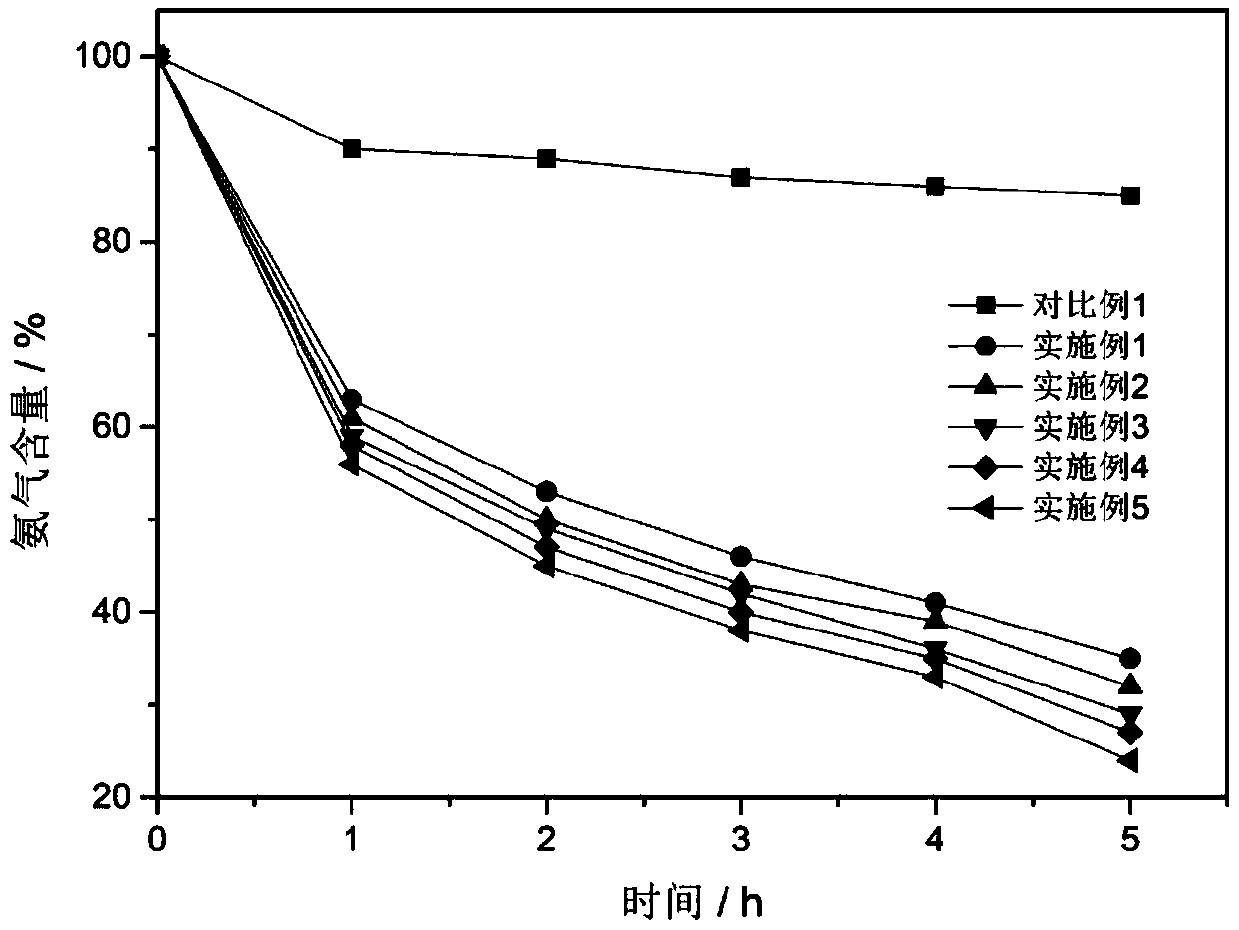

Examples

Embodiment 1

[0030] A preparation method of ammonia plant deodorant, comprising the following steps:

[0031] S1. Add 15kg of plant extracts to 50kg of water, stir thoroughly for 30 minutes and set aside; wherein, the plant extracts include 7.5kg of lemon eucalyptus oil and 7.5kg of Burnet eucalyptus extract;

[0032] S2. Ultrasonic disperse 5 kg of cuprous oxide in 20 kg of absolute ethanol, then add 15 kg of tetrabutyl titanate, and then add 5 kg of ethanol solution with a mass concentration of 80%, centrifuge the product after fully reacting, and wash with alcohol , dried in vacuum at 150°C for 4 hours to obtain a solid powder;

[0033] S3. Grind the solid powder evenly and add it to the solution in S1, then add 5 kg of peraluminate, and stir thoroughly for 4 hours to prepare a plant deodorant. The peraluminate here is the general term for calcium aluminate minerals, which is CaO-Al 2 o 3 Minerals produced by the system include dodecaaluminate heptaaluminate and monocalcium hexaalumi...

Embodiment 2

[0038] A preparation method of ammonia plant deodorant, comprising the following steps:

[0039] S1. Add 20 kg of plant extracts to 55 kg of water, stir thoroughly for 40 minutes and set aside; wherein, the plant extracts include 10 kg of Burnet elm extract and 10 kg of Lagerstroemia crape myrtle extract;

[0040] S2. Ultrasonic disperse 7 kg of cuprous oxide in 25 kg of absolute ethanol, then add 20 kg of metatitanic acid, and then add 5 kg of ethanol solution with a mass concentration of 80%, centrifuge the product after sufficient reaction, wash with alcohol, and Vacuum drying at 160°C for 5 hours to obtain a solid powder;

[0041] S3. Grind the solid powder evenly and add it to the solution in S1, then add 7kg of peraluminate, and stir thoroughly for 5 hours to prepare a plant deodorant. In this embodiment, the peraluminate is monocalcium hexaaluminate.

[0042] Wherein, the preparation method of burnet extract or crape myrtle extract is:

[0043] A1. Grind Burnet or La...

Embodiment 3

[0046] A preparation method of ammonia plant deodorant, comprising the following steps:

[0047] S1. Add 20kg of plant extracts to 60kg of water, stir thoroughly for 50 minutes and set aside; wherein, the plant extracts include 10kg of crape myrtle extract and 10kg of rose extract;

[0048] S2, 10kg of cuprous oxide is ultrasonically dispersed in 25kg of dehydrated alcohol, then 20kg of titanium trichloride / titanium tetrachloride mixed solution is added, and then 5kg of mass concentration is added to be 80% ethanol solution, fully reacted The product was separated by centrifugation, washed with alcohol, and dried in vacuum at 170°C for 6 hours to obtain a solid powder; wherein, the concentrations of the titanium trichloride solution and the titanium tetrachloride solution were both 0.5mol / L, and the titanium trichloride solution and the tetrachloride solution were The mass ratio of titanium dioxide solution is 1:3.

[0049] S3. Grind the solid powder evenly and add it to the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com