Method for preparing high-purity vanadium pentoxide by reducing and hydrolyzing sodium vanadium solution

A technology of vanadium pentoxide and sodiumization, which is applied in the field of preparation of high-purity vanadium pentoxide by reduction hydrolysis of sodium vanadium solution, can solve the problems of poor impurity removal effect, low operating cost, and small environmental pollution, and meet the requirements of the equipment environment Friendly, strong adaptability of raw materials, improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

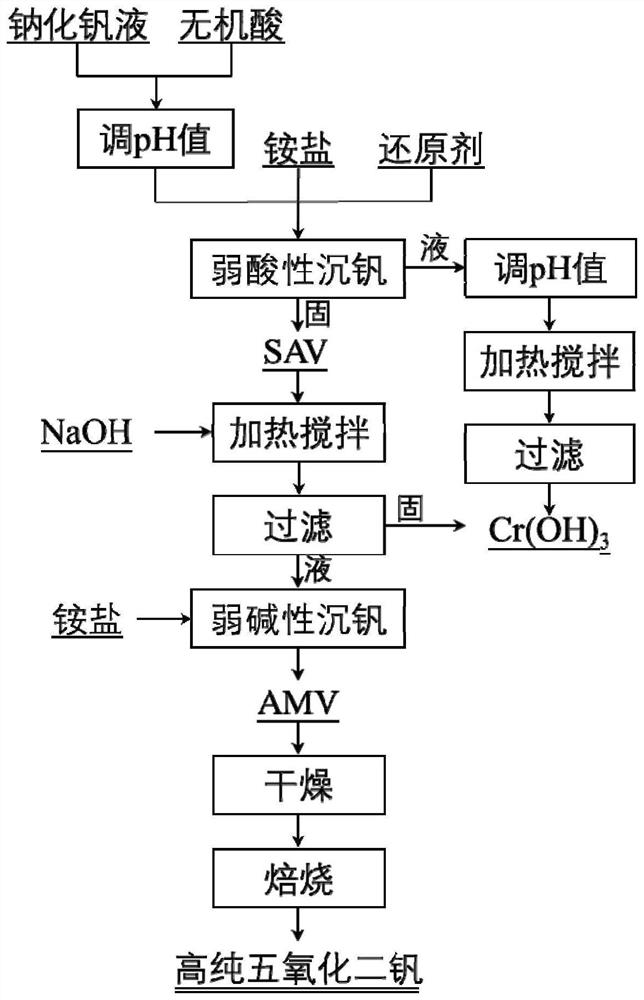

Method used

Image

Examples

Embodiment 1

[0045] This example is used to illustrate the method for preparing high-purity vanadium pentoxide by reduction hydrolysis of sodium vanadium solution according to the present invention.

[0046] (1) Measure 500ml of sodium vanadium solution, add sulfuric acid dropwise to adjust the pH to neutral, add 5.85g oxalic acid dihydrate, then add sulfuric acid dropwise to control the pH to 1.5, and stir at 100°C for 0.5h. After the reaction is finished, filter, beat and wash the filter cake with deionized water twice, filter and dry to obtain a hydrolyzate.

[0047] (2) Dissolve the dried hydrolyzate in sodium hydroxide solution, control the end point pH value to 10.5, stir and react at 100°C for 3h, filter to obtain dark green filter cake and 485ml colorless vanadium solution, TV is 42.06g / L .

[0048] (3) Add 51.2 g of ammonium sulfate to the colorless vanadium solution, stir and react for 0.5 h, filter, wash and dry after the reaction to obtain a white solid.

[0049] (4) Roast th...

Embodiment 2

[0051] This example is used to illustrate the method for preparing high-purity vanadium pentoxide by reduction hydrolysis of sodium vanadium solution according to the present invention.

[0052] (1) Measure 500ml of sodium vanadium solution, add sulfuric acid dropwise to adjust the pH to neutral, add 81ml of vanadyl sulfate solution with a concentration of 2.85mol / L, then add sulfuric acid dropwise to control the pH to 2.0, and stir at 95°C Reaction 2h. After the reaction is finished, filter, beat and wash the filter cake with deionized water twice, filter and dry to obtain a hydrolyzate.

[0053] (2) Dissolve the dried hydrolyzate in sodium hydroxide solution, control the end point pH value to 11.5, stir and react at 95°C for 9h, filter to obtain dark green filter cake and 565ml colorless vanadium solution, TV is 37.54g / L .

[0054] (3) Add 40.83 g of ammonium carbonate to the colorless vanadium solution, stir and react for 1 h, filter, wash and dry after the reaction to ob...

Embodiment 3

[0057] This example is used to illustrate the method for preparing high-purity vanadium pentoxide by reduction hydrolysis of sodium vanadium solution according to the present invention.

[0058] (1) Measure 500ml of sodium vanadium solution, add sulfuric acid dropwise to adjust the pH to neutral, add 12.9g of sodium metabisulfite, then add sulfuric acid dropwise to control the pH to 2.5, and stir at 98°C for 1 hour. After the reaction is finished, filter, beat and wash the filter cake with deionized water twice, filter and dry to obtain a hydrolyzate.

[0059] (2) Dissolve the dried hydrolyzate in sodium hydroxide solution, control the end point pH value to 11, stir and react at 98°C for 6 hours, filter to obtain dark green filter cake and 487ml colorless vanadium solution, TV is 43.86g / L .

[0060] (3) Add 60.49 g of ammonium chloride to the colorless vanadium solution, stir and react for 2 hours, filter, wash and dry after the reaction to obtain a white solid.

[0061] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com