Manganese slag percolation wastewater treatment system

A wastewater treatment system and wastewater technology, which are applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as waste of resources and poor treatment effect, and achieve reduction in recycling and utilization. cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

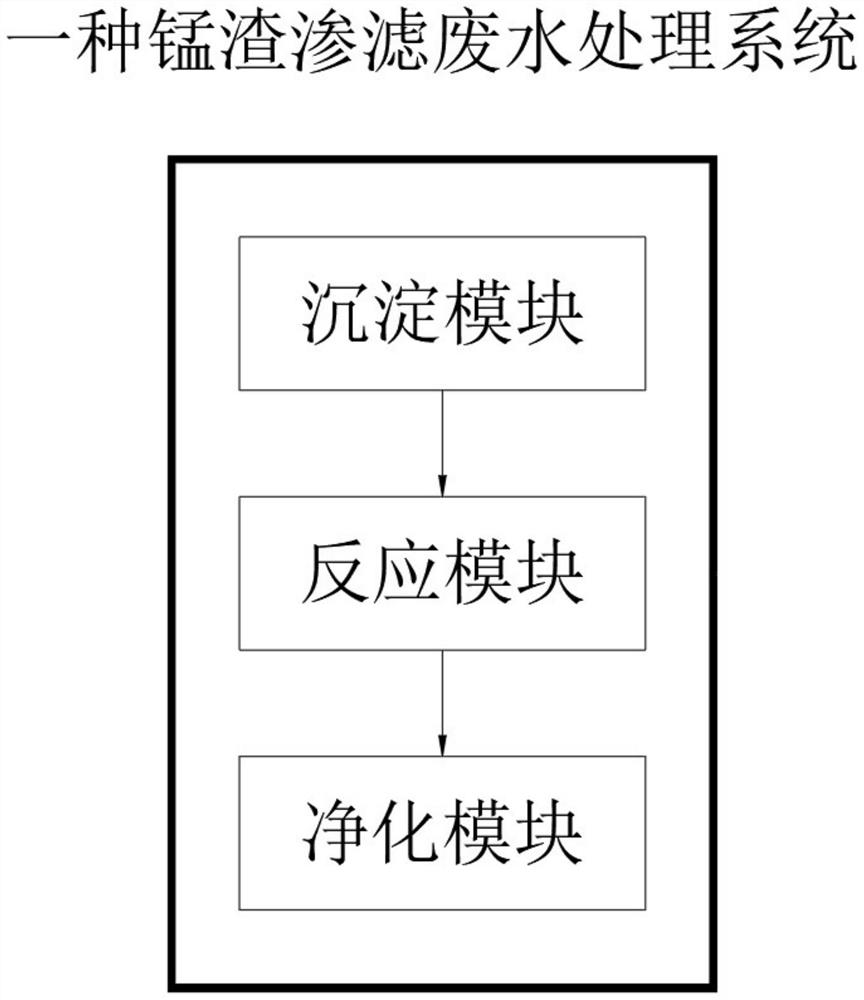

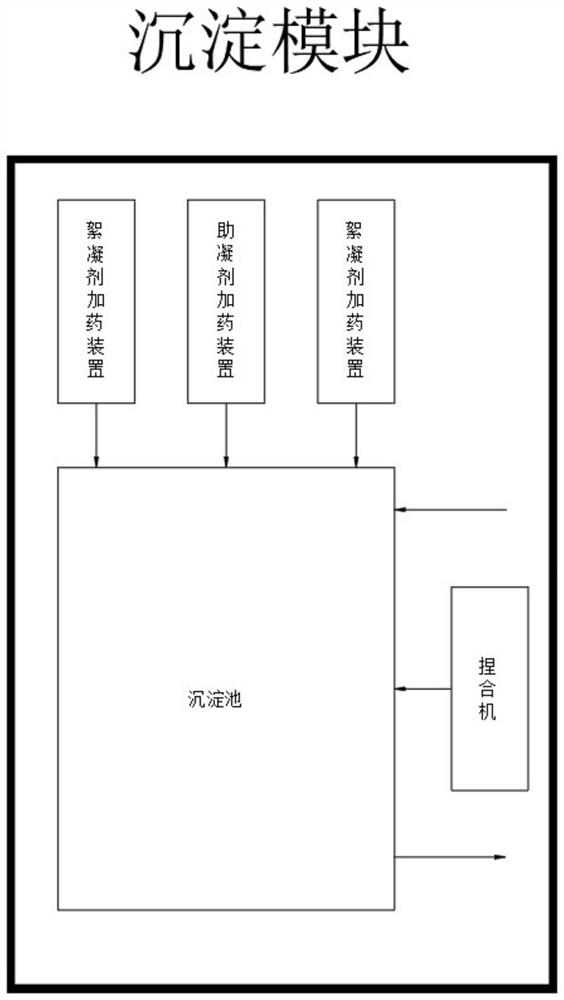

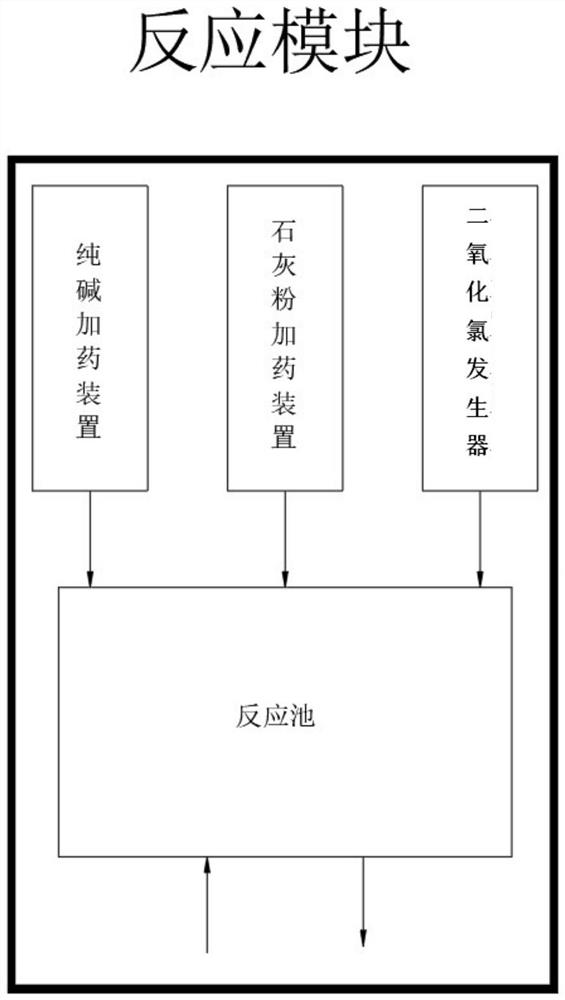

[0038] The present invention provides a technical solution: a high-efficiency graphene film identification system based on surface friction, see figure 1 , 2 , 3 and 4, including a precipitation module, a reaction module and a purification module, the precipitation module includes a sedimentation tank, a coagulant dosing device, a kneader and two flocculant dosing devices, and the reaction module includes Soda ash dosing device, lime powder dosing device, chlorine dioxide generator and reaction pool. medicine device.

[0039] Further, the precipitation module includes the following steps:

[0040] Step 1, adding waste water into the sedimentation tank, adding inorganic flocculant, organic flocculant and coagulant aid to the sedimentation tank through a coagulant dosing device and two flocculant dosing devices;

[0041] Step 2: Mix the waste water, flocculant and coagulant aid through the two paddles of the kneader to speed up the separation and connection of impurities in t...

Embodiment 2

[0056] The present invention provides a technical solution: a high-efficiency graphene film identification system based on surface friction, see figure 1 , 2 , 3 and 4, including a precipitation module, a reaction module and a purification module, the precipitation module includes a sedimentation tank, a coagulant dosing device, a kneader and two flocculant dosing devices, and the reaction module includes Soda ash dosing device, lime powder dosing device, chlorine dioxide generator and reaction pool. medicine device.

[0057] Further, the precipitation module includes the following steps:

[0058] Step 1, adding waste water into the sedimentation tank, adding inorganic flocculant, organic flocculant and coagulant aid to the sedimentation tank through a coagulant dosing device and two flocculant dosing devices;

[0059] Step 2: Mix the waste water, flocculant and coagulant aid through the two paddles of the kneader to speed up the separation and connection of impurities in t...

Embodiment 3

[0074] The present invention provides a technical solution: a high-efficiency graphene film identification system based on surface friction, see figure 1 , 2 , 3 and 4, including a precipitation module, a reaction module and a purification module, the precipitation module includes a sedimentation tank, a coagulant dosing device, a kneader and two flocculant dosing devices, and the reaction module includes Soda ash dosing device, lime powder dosing device, chlorine dioxide generator and reaction pool. medicine device.

[0075] Further, the precipitation module includes the following steps:

[0076] Step 1, adding waste water into the sedimentation tank, adding inorganic flocculant, organic flocculant and coagulant aid to the sedimentation tank through a coagulant dosing device and two flocculant dosing devices;

[0077] Step 2: Mix the waste water, flocculant and coagulant aid through the two paddles of the kneader to speed up the separation and connection of impurities in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com