High-reflection photovoltaic coating and preparation method thereof

A highly reflective, photovoltaic technology, applied in reflective/signal coatings, coatings, etc., can solve the problem of lack of good coatings, and achieve the effect of improving fluidity and viscosity, improving UV resistance and good reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

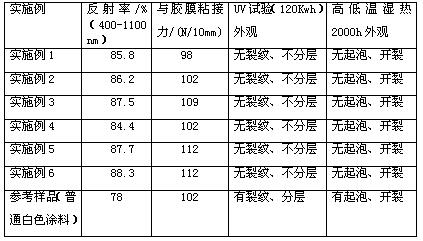

Examples

Embodiment 1

[0037] Preparation of highly reflective microspheres: glass powder and nano-T i o 2 , Stir evenly under the conditions of water bath temperature of 20°C and rotational speed of 2000r / min r / min to prepare a modified functional filler; mix magnesium chloride, sodium lactate and water evenly to prepare a suspension polymerization liquid; the obtained filler After mixing with liquid, emulsifying and dispersing to form a suspension solution, stirring and reacting in a high-pressure reactor to realize suspension polymerization, filtering, and drying the filter cake to obtain the high-reflection microspheres. Mix polytetrafluoroethylene resin, high-reflective microspheres, titanium dioxide, diethylenetriamine, fluorocarbon resin, and ethylene oxide thoroughly, then cool to room temperature, put them in a centrifuge and rotate for 30 seconds to form a photovoltaic coating .

Embodiment 2

[0039] Preparation of highly reflective microspheres: glass powder and nano-T i o 2 , Stir evenly under the conditions of water bath temperature of 30°C and rotational speed of 2000r / min r / min to prepare modified functional filler; mix magnesium chloride, sodium lactate and water evenly to prepare suspension polymerization liquid; the obtained filler After mixing with liquid, emulsifying and dispersing to form a suspension solution, stirring and reacting in a high-pressure reactor to realize suspension polymerization, filtering, and drying the filter cake to obtain the high-reflection microspheres. Mix and stir polyvinylidene fluoride resin, high-reflective microspheres, barium sulfate, diethylenetriamine, fluorocarbon resin, and ethylene oxide thoroughly, then cool to room temperature, put them in a centrifuge and spin for 20 seconds to form photovoltaics coating.

Embodiment 3

[0041] Preparation of highly reflective microspheres: glass powder and nano-T i o 2 , Stir evenly under the conditions of water bath temperature of 20°C and rotational speed of 2000r / min r / min to prepare a modified functional filler; mix magnesium chloride, sodium lactate and water evenly to prepare a suspension polymerization liquid; the obtained filler After mixing with liquid, emulsifying and dispersing to form a suspension solution, stirring and reacting in a high-pressure reactor to realize suspension polymerization, filtering, and drying the filter cake to obtain the high-reflection microspheres. Mix ethoxyethoxyethylacrylate, high-reflection microspheres, talc powder, diethylenetriamine, fluorocarbon resin, and ethylene oxide thoroughly, then cool to room temperature, and put them in a centrifuge for centrifugal rotation 15 seconds to form a photovoltaic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com