Preparation method of silicon dioxide/ultra-high molecular weight polyethylene non-woven cloth

A technology of ultra-high molecular weight and silica, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problem of affecting the mechanical properties of STF/ultra-high molecular weight polyethylene non-woven fabrics and poor wettability of ultra-high molecular weight polyethylene fibers , Unable to guarantee uniformity and other issues, to achieve the effect of novel process route, light weight and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

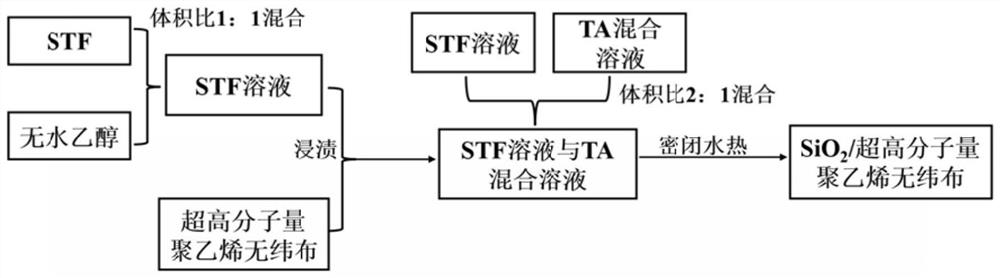

[0048] 1) Put PEG200 in a beaker and add SiO to one side 2 While stirring the powder, add a certain amount of SiO 2 Stir again for 2 hours, and put it into a vacuum drying oven at 80°C for 24 hours of vacuum defoaming to obtain STF, wherein, SiO 2 The particle size is 7-40nm, SiO 2 The solids content was 15%.

[0049] 2) Pretreat the ultra-high molecular weight polyethylene non-weft cloth by ultrasonicating the ultra-high molecular weight polyethylene non-weft cloth in acetone and ethanol solutions for 2 minutes, rinse with deionization several times and dry at 80°C for 1 hour .

[0050] 3) Soak the pretreated ultra-high molecular weight polyethylene non-weft cloth in the STF solution for 15 minutes, then take it out and put it in a vacuum drying oven at 80°C for 6 hours to obtain the ultra-high molecular weight polyethylene cloth impregnated with the STF solution. Polyethylene non-weft cloth, wherein the STF solution is composed of STF and absolute ethanol with a volume r...

Embodiment 2

[0055] 1) Put PEG200 in a beaker and add SiO to one side 2 While stirring the powder, add a certain amount of SiO 2 Stir again for 2 hours, and put it into a vacuum drying oven at 80°C for 24 hours of vacuum defoaming to obtain STF, wherein, SiO 2 The particle size is 7-40nm, SiO 2 The solids content was 15%.

[0056] 2) Pretreat the ultra-high molecular weight polyethylene non-weft cloth by ultrasonicating the ultra-high molecular weight polyethylene non-weft cloth in acetone and ethanol solutions for 2 minutes, rinse with deionization several times and dry at 80°C for 1 hour .

[0057] 3) impregnate the pretreated ultra-high molecular weight polyethylene non-weft cloth in 15% SiO 2 The solid content of the STF solution for 15 minutes, then take it out and put it in a vacuum drying oven at 80 ° C for 6 hours to obtain an ultra-high molecular weight polyethylene non-woven fabric impregnated with the STF solution, wherein the STF solution is obtained by volume ratio It is ...

Embodiment 3

[0060] 1) Put PEG200 in a beaker and add SiO to one side 2 While stirring the powder, add a certain amount of SiO 2 Stir again for 2 hours, and put it into a vacuum drying oven at 80°C for 24 hours of vacuum defoaming to obtain STF, wherein, SiO 2 The particle size is 7-40nm, SiO 2 The solids content was 15%.

[0061] 2) Pre-treat the ultra-high molecular weight polyethylene non-weft cloth, ultrasonic the ultra-high molecular weight polyethylene non-weft cloth in acetone and ethanol solutions for 2 minutes, rinse with deionization several times and dry at 80°C for 1 hour .

[0062] 3) impregnate the pretreated ultra-high molecular weight polyethylene non-weft cloth in 15% SiO 2 solid content of STF solution for 15 minutes, then take it out and dry it in a vacuum oven at 80°C for 6 hours to obtain SiO 2 / Ultra-high molecular weight polyethylene non-weft cloth, wherein the STF solution is composed of STF and absolute ethanol with a volume ratio of 1:1.

[0063] 4) Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com