Duplex stainless steel etching agent and etching method

A technology of duplex stainless steel and etchant, which is applied in the direction of measuring devices, instruments, and material analysis through optical means, etc., can solve the problems of high temperature time consumption, reduce work efficiency, safety protection, etc., and achieve obvious contrast, etch reproducibility and Good stability and little physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

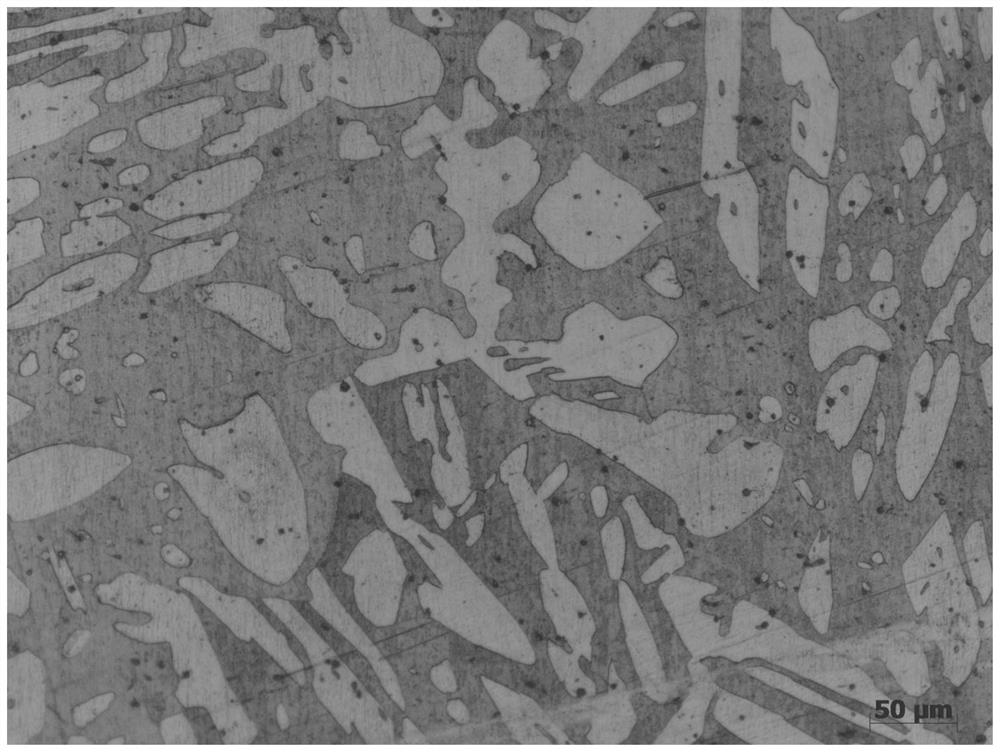

Embodiment 1

[0042] Configuration 20g etching agent, by weight percent is 30% methanesulfonic acid, 3% sorbic acid, 1.5% water-soluble chitosan, 1.5% sodium laurate, 7.5% ethanol and the deionized water of balance formulated.

[0043] The metallographic etchant prepared in this embodiment is used to display the metallographic structure of duplex stainless steel, and the specific method is as follows:

[0044] Step 1. Prepare the 2205 dual-phase steel sample, and inlay the sample according to the following method to facilitate the next step of grinding. Specimen inlay method: Put the 2205 dual-phase steel sample into the inlay groove of the metallographic inlay machine. When placing the sample, pay attention to the observation side of the sample facing down, add 10g of HM1 inlay material, then put it into the die and press the die Press it into the mosaic groove, cover and fix it, then start heating (heat to 135°C) and turn the first wheel to increase the pressure in the mosaic groove, and...

Embodiment 2

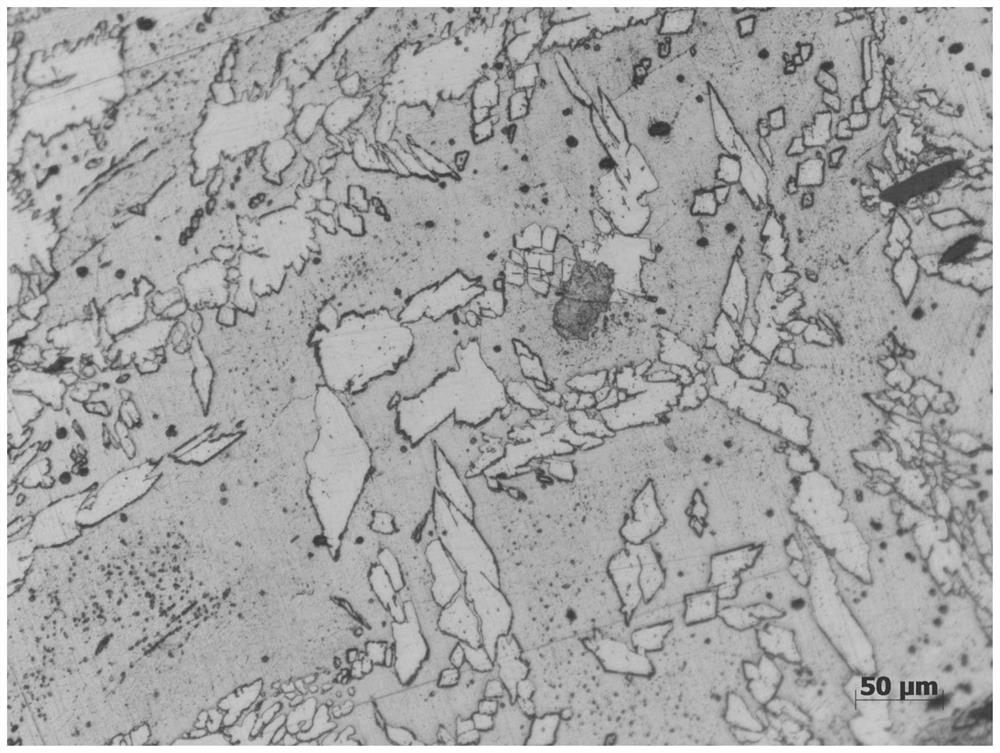

[0051] Configuration 20g etching agent, by weight percent is 40% methanesulfonic acid, 4% sorbic acid, 2% water-soluble chitosan, 2% sodium laurate, 10% ethanol and the deionized water of balance formulated.

[0052] The metallographic etchant prepared in this embodiment is used to display the metallographic structure of duplex stainless steel, and the specific method is as follows:

[0053] Step 1: Prepare the 2205 dual-phase steel sample, and inlay the sample according to the method in Example 1, so as to facilitate the next step of grinding.

[0054] Step 2. Put the inlaid sample on the metallographic pre-grinder, and grind it from coarse grinding to fine grinding through 400# water-based sandpaper, 600# water-based sandpaper, 1200# water-based sandpaper, and 2000# water-based sandpaper respectively. 500r / min; during the grinding process, continuously add water to cool, and after 10 minutes, when the scratches are all in the same direction, one grinding is completed, and t...

Embodiment 3

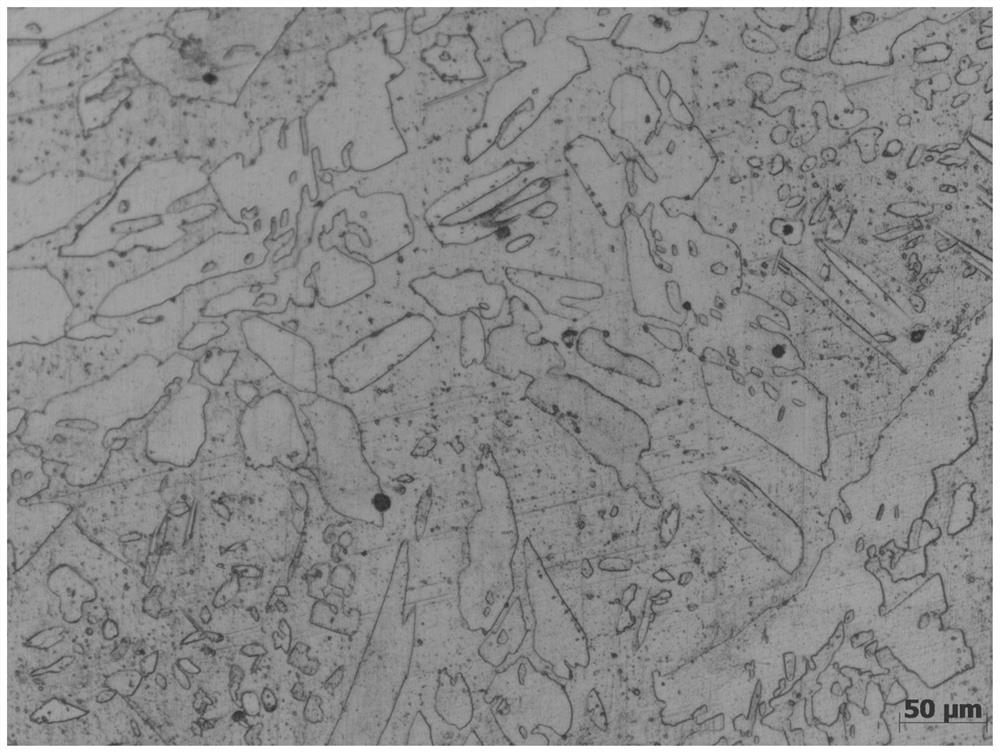

[0060] Configuration 20g etching agent, by weight percentage is 20% methanesulfonic acid, 2% sorbic acid, 1% water-soluble chitosan, 1% sodium laurate, 5% ethanol and the deionized water of remainder formulated. .

[0061] The metallographic etchant prepared in this embodiment is used to display the metallographic structure of duplex stainless steel, and the specific method is as follows:

[0062] Step 1: Prepare the 2205 dual-phase steel sample, and inlay the sample according to the method in Example 1, so as to facilitate the next step of grinding.

[0063] Step 2. Put the inlaid sample on the metallographic pre-grinder, and grind it from coarse grinding to fine grinding through 400# water-based sandpaper, 600# water-based sandpaper, 1200# water-based sandpaper, and 2000# water-based sandpaper respectively. 500r / min; during the grinding process, continuously add water to cool, and after 10 minutes, when the scratches are all in the same direction, one grinding is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com