Microprism array manufacturing method based on laser direct writing photoetching technology

A manufacturing method and laser direct writing technology, which are applied in prisms, microlithography exposure equipment, photolithography process exposure devices, etc. problems, to achieve the effect of improving performance and flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

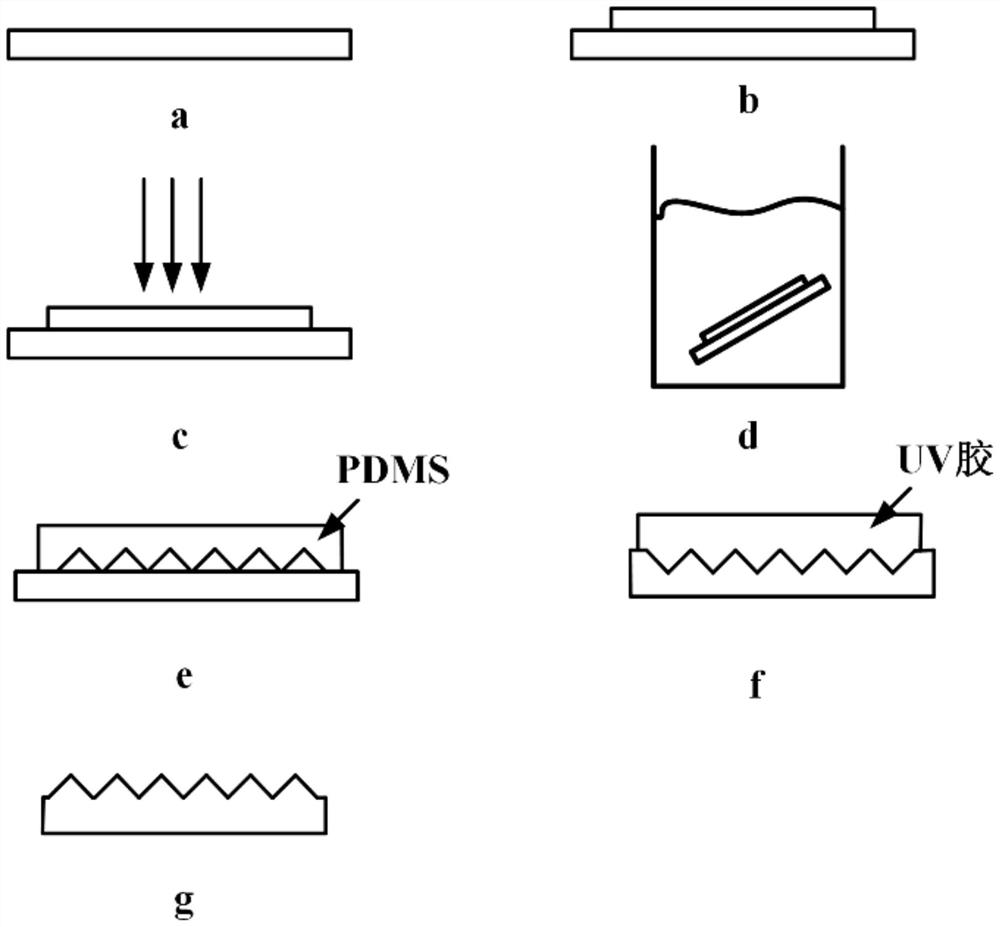

[0033] figure 1 It is a flowchart of a method for manufacturing a microprism array based on laser direct writing lithography technology according to an embodiment of the present invention. Combine below figure 1 Describe in detail. The manufacturing method of this embodiment specifically includes the following steps a-g.

[0034] Step a: Select a silicon wafer as the substrate, and clean the surface of the silicon wafer with nitrogen, such as figure 1 (a) shown.

[0035] Step b: Select a microprism array pattern with a height of 1.5 microns, spin-coat photoresist-S1818 on the silicon substrate, spin-coat at a speed of 3000rmp / min, and pre-bake for 15min, such as figure 1 In (b) shown. Specifically, this step also includes: step b1: before spin-coating the photoresist, determine the height of the photoresist according to the height of the microprisms of the desired microprism array; step b2: select the photoresist for spin coating according to the height of the photoresist...

Embodiment 2

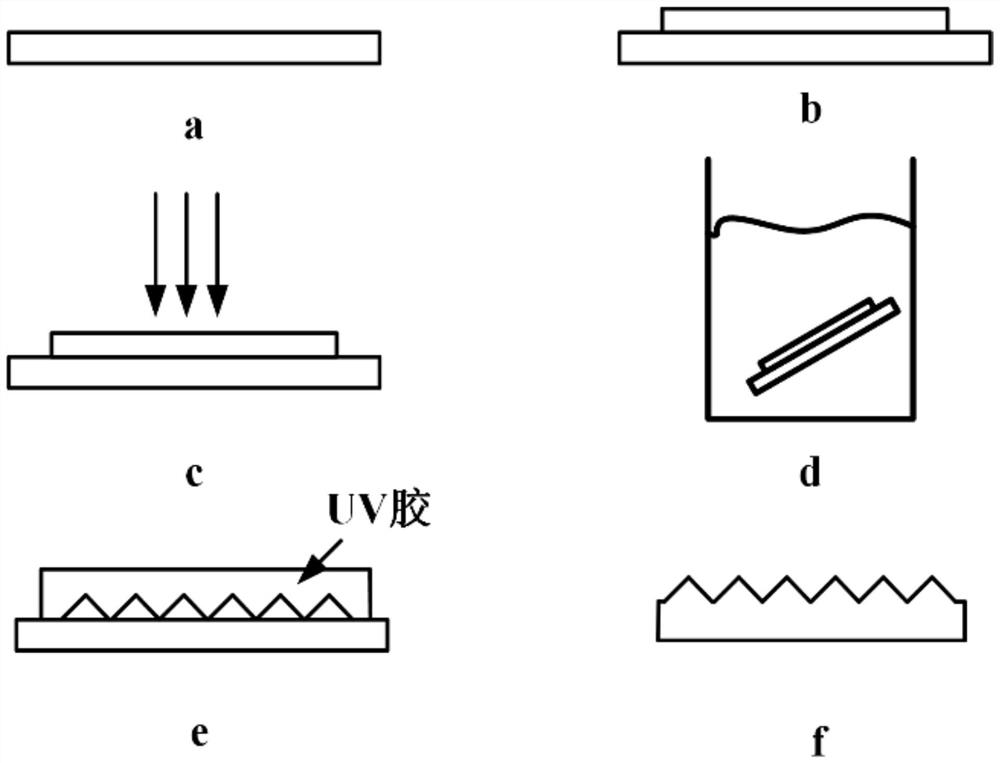

[0043] Step a: Select a silicon wafer as the substrate, and clean the surface of the silicon wafer with nitrogen, such as figure 2 (a) shown.

[0044] Step b: Select a microprism array pattern with a height of 1.5 microns, spin-coat photoresist-S1818 on the silicon substrate, spin-coat at a speed of 3000rmp / min, and pre-bake for 15min, such as figure 2 (b) shown.

[0045] Step c: Input the grayscale image of the microprism array into the laser direct writing device, select the spot size to be 200nm, the exposure dose to be 80mj / mm2, and the compensation voltage to be -1V. Then, the photoresist is exposed by laser direct writing lithography, such as figure 2 (c) shown. In this step, the input grayscale image of the microprism array is a negative grayscale image. In this embodiment, the laser is a UV laser.

[0046] Step d: Make a developer at a ratio of 3:1, and develop the exposed photoresist with the S1818 special developer, and the developing time is 5 minutes, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com