Cooling smoke tube

A technology for tobacco pipes and tobacco powder, which is applied in the fields of tobacco, cigar manufacturing, and application, can solve the problems of insufficient support strength, no pores, easy bending and deformation, etc., and achieves good cooling effect, reduced suction resistance, and good phase transition. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

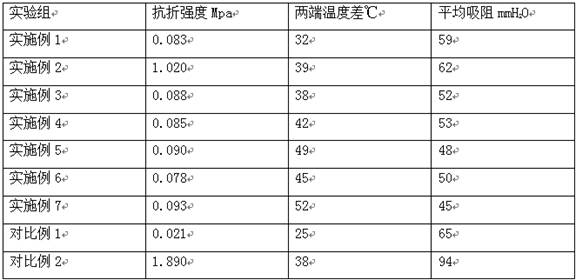

Examples

Embodiment 1

[0023] A cooling smoke pipe, prepared by the following steps:

[0024] According to parts by mass, 73 parts of smoke powder, 4.2 parts of hydroxypropyl methylcellulose, 1.4 parts of polyethylene glycol, 2.1 parts of glycerin, 3.5 parts of oleic acid, 15.8 parts of water, a total of 100 parts, after mixing, added to the mixing The mixture was mixed in the feeder for 30 minutes to obtain the tobacco mixture. Pour the tobacco mixture into a vacuum mud refiner, circulate the mud for 3 times under the condition of water cooling at 25°C to obtain tobacco mud, take out the mud and put it into an extruder, extrude it into a tubular structure at 120°C, place After air-drying at 25° C. for three days, it was cut into 2 cm long pieces to obtain a cooling smoke pipe.

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

[0027] In this application, the mud material is taken out and put into the extruder, and at 120°C, a tubular structure with a spacer and a flue gas channel is extruded with a "seven-core" and "six-fan" extrusion die.

Embodiment 3

[0029] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

[0030] Before extruding, the tobacco mud obtained by circulating mud 3 times was manually kneaded, and every kneading 5min was added with a quality of 0.05% sodium chloride and a quality of 0.05% of the tobacco mud quality. urea. Kneading for 30 minutes in total, adding 0.3% sodium chloride and 0.3% urea in total to obtain the initial material. Then wrap the primary material with a polyethylene film and place it at 25°C and 40% humidity to age for 24-48 hours to obtain a masterbatch. Then put the masterbatch into the extruder to extrude.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com