Decorative sheet with electron beam hardened surface treatment layer and method of making the same

A surface treatment layer and decorative board technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of large labor force, poor flatness, reduction of hardness and comprehensive performance of the surface treatment layer of decorative boards, and achieve The effect of improving overall performance and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

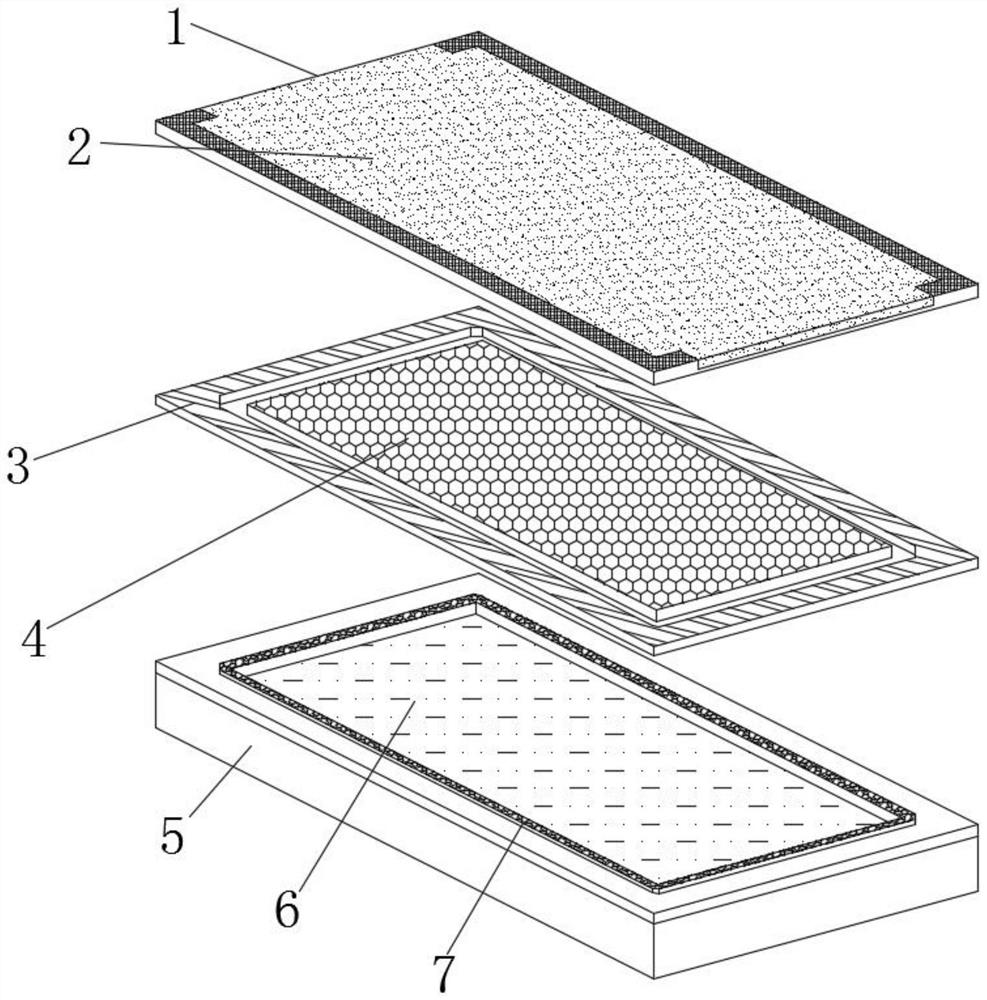

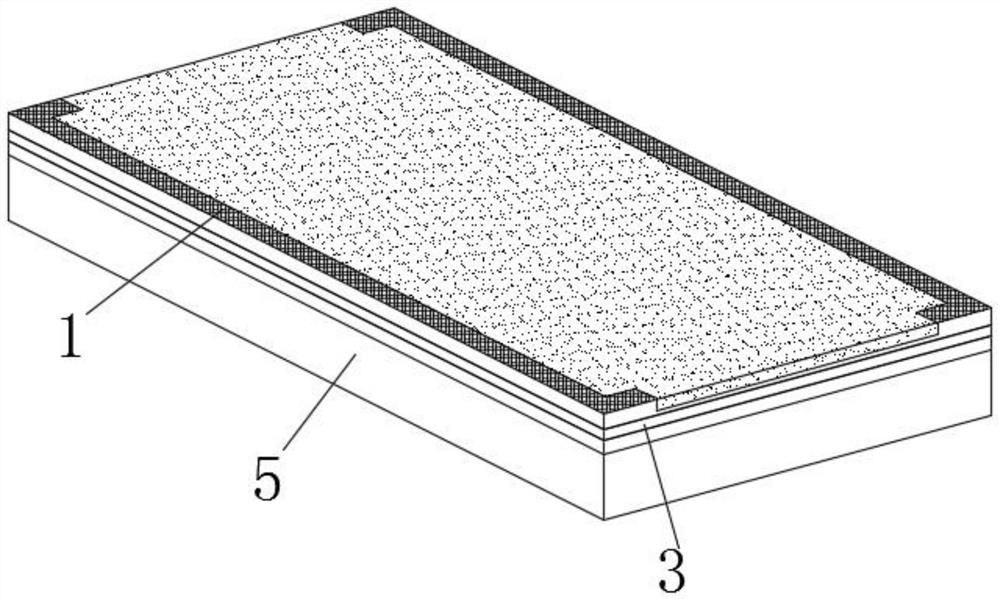

[0044] Example 1, as Figure 1-2 As shown, before the decorative paperboard 1 is covered on the surface of the board body 5, a concave layer 6 can be opened on the top surface of the board body 5, and the gypsum core board 4 can be embedded in the inner side of the concave layer 6, and the outer edge of the concave layer 6 can be laid with annular Flange 7, and make the annular raised edge 7 and the embedded gypsum core board 4 at the same height, and then lay the back-shaped prepreg 3 on the edge of the board body 5, so that the back-shaped prepreg 3 and the annular raised edge 7 and the gypsum core board 4 are in the same height. At the same level, at this time, an adhesive layer can be applied on the surfaces of the return prepreg 3, the gypsum core board 4 and the annular convex edge 7, and then the decorative cardboard 1 is covered as a whole, and the contact of the return prepreg 3 forms a semi-cured positioning. Then, it is sent into the drying device, so that the decor...

Embodiment 2

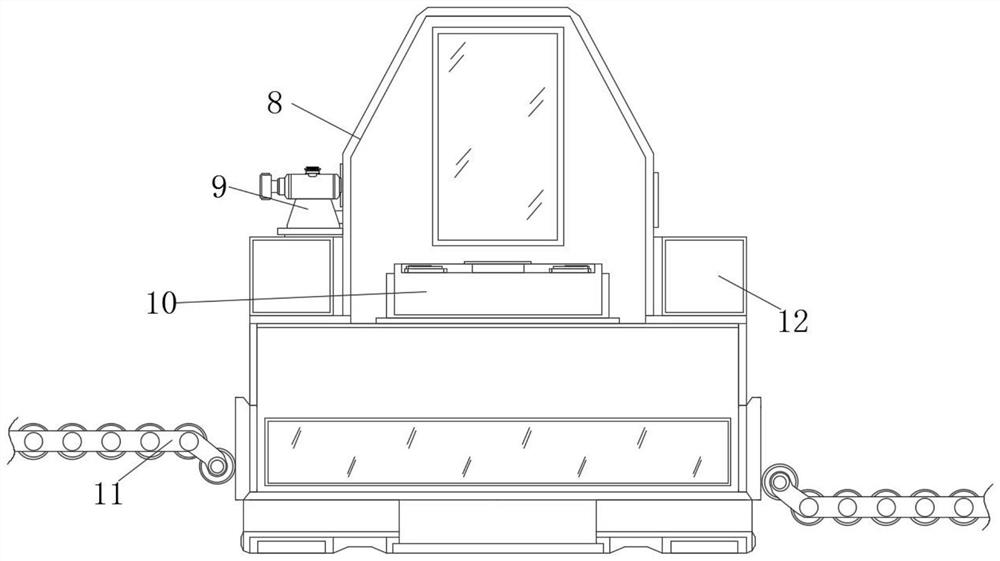

[0045] Example 2, as Figure 3-6 As shown in the figure, when the electron beam device is in use, the opening of the discharge chamber 14 can be sealed or opened through the lifting and lowering of the two sets of plug valves 1209. The notch opened on the bottom surface is fitted into the outer side wall of the track 15 and the inner guide layer, so that the plug valve 1209 is completely sealed to the discharge chamber 14, which promotes the vacuum chamber 13 to form a vacuum state, while the traveling 16 and the horizontal displacement mechanism 18 The internal threaded pipe installed inside is fixedly connected. When horizontal displacement is required, the third bevel gear group can be driven to force the threaded rod to rotate through the activation of the servo motor base, so that the traveling car 16 can be horizontally displaced under the guidance of the track 15, and promote the rotation of the threaded rod. The endless conveyor belt 17 carries out the work of receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com