Preparation method of high-durability 3, 4-dihydroxyphenylalanine chelated cerium ion composite proton exchange membrane

A hydroxyphenylalanine, proton exchange membrane technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve problems such as catalytic layer damage, reduce ion dissolution and migration, simple operation methods, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a high chemical durability 3,4-dihydroxyphenylalanine chelated cerium ion composite proton exchange membrane, comprising the following steps:

[0025] (1) 23g perfluorosulfonic acid resin is added to water, n-propanol, DMSO mass ratio is 4.5:4.5:1 in the 77g mixed solvent, stirs 24h at room temperature, obtains uniform 23wt% PFSA ionomer solution ;

[0026] (2) Mix 3,4-dihydroxyphenylalanine and cerium salt (III) in 2ml of water-ethanol solution with a volume ratio of 1:1 according to different molar ratios, and stir to obtain 3,4-dihydroxyphenylalanine Ceric acid cerium complex dispersion;

[0027] (3) the 3,4-dihydroxyphenylalanine cerium complex dispersion in (2) is added in the 23wt% PFSA ionomer solution of 3g, stirs 12h, obtains the ionomer solution of uniform dispersion, then The above solution was dispersed for 0.5 h with an ultrasonic cleaner. These casting solutions were poured onto flat glass and then scraped with a wire rod. After...

Embodiment 1

[0036] A method for preparing a high-durability 3,4-dihydroxyphenylalanine chelated cerium ion composite proton exchange membrane, comprising the following steps:

[0037] (1) 23g perfluorosulfonic acid resin is added to water, n-propanol, DMSO mass ratio is 4.5:4.5:1 in the 77g mixed solvent, stirs 24h at room temperature, obtains uniform 23wt% PFSA ionomer solution ;

[0038] (2) Mix 0.0130g 3,4-dihydroxyphenylalanine and 0.0286g cerium nitrate hexahydrate in 2ml water-ethanol solution with a volume ratio of 1:1, and stir for 12h to obtain 3,4-dihydroxyphenylalanine Ceric acid cerium complex dispersion;

[0039] (3) the 3,4-dihydroxyphenylalanine cerium complex dispersion in (2) is added in the 23wt% PFSA ionomer solution of 3g, stirs 12h, obtains the ionomer solution of uniform dispersion, then The above solution was dispersed for 0.5 h with an ultrasonic cleaner. These casting solutions were poured onto flat glass and then scraped with a wire rod. Afterwards, drying at...

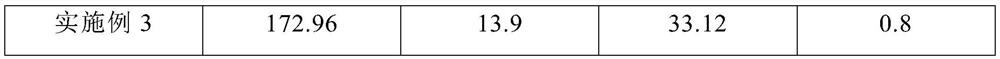

Embodiment 2

[0041] A method for preparing a high-durability 3,4-dihydroxyphenylalanine chelated cerium ion composite proton exchange membrane, comprising the following steps:

[0042] (1) 23g perfluorosulfonic acid resin is added to water, n-propanol, DMSO mass ratio is 4.5:4.5:1 in the 77g mixed solvent, stirs 24h at room temperature, obtains uniform 23wt% PFSA ionomer solution ;

[0043] (2) Mix 0.0260g 3,4-dihydroxyphenylalanine and 0.0286g cerium nitrate hexahydrate in 2ml water-ethanol solution with a volume ratio of 1:1, and stir for 12h to obtain 3,4-dihydroxyphenylalanine Ceric acid cerium complex dispersion;

[0044] (3) the 3,4-dihydroxyphenylalanine cerium complex dispersion in (2) is added in the 23wt% PFSA ionomer solution of 3g, stirs 12h, obtains the ionomer solution of uniform dispersion, then The above solution was dispersed for 0.5 h with an ultrasonic cleaner. These casting solutions were poured onto flat glass and then scraped with a wire rod. Afterwards, drying at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com