Concrete early-stage maintenance liquid preparation and concrete early-stage maintenance method

A technology of early maintenance and liquid preparation, which is applied in the manufacture of tools, ceramic molding machines, etc., and can solve problems such as surface cracking, volume reduction, and non-flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

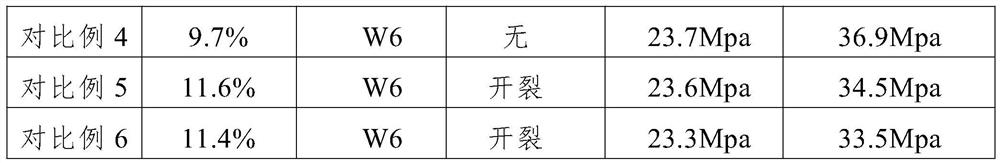

Examples

Embodiment 1

[0028] This embodiment provides a concrete early curing liquid preparation, the composition of which is: 35% ethyl orthosilicate, 10% sodium fluorosilicate, 2% sodium citrate, 1% dodecyldimethylphenoxyethyl ammonium bromide, 0.5% ethylene glycol, and water as the balance.

Embodiment 2

[0030] This embodiment provides a concrete early curing liquid preparation, its composition is: 30% tetraethyl orthosilicate, 10% sodium fluorosilicate, 2% sodium silicate, 2% sodium citrate, 1.5% lauryl Dimethylphenoxyethylammonium bromide, 0.25% ethylene glycol, and the balance water.

Embodiment 3

[0032] This embodiment provides a concrete early curing liquid preparation, its composition is: 30% tetraethyl orthosilicate, 10% sodium fluorosilicate, 2% sodium silicate, 2% sodium citrate, 1.5% CTAB, 0.25% Ethylene glycol and the balance are water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com