Archaized brick with antiskid effect and preparation method of archaized brick

An antique brick and anti-slip technology, applied in the field of antique brick, can solve the problems of poor inkjet pattern clarity, poor anti-slip performance, poor anti-fouling performance, etc., and achieve the effects of reducing luminosity, good color development, and good permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

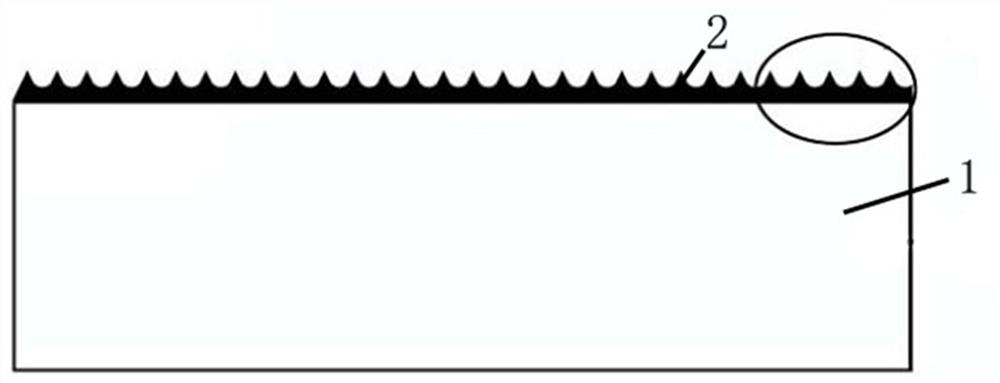

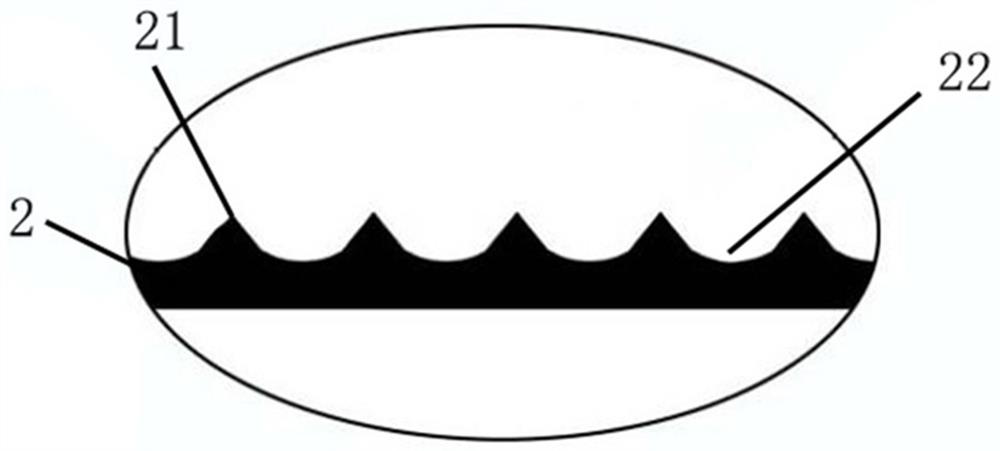

[0038] An antique brick with anti-slip effect, comprising an antique brick body and an anti-slip functional glaze layer covering the surface of the body, the anti-slip functional glaze layer includes an anti-slip surface glaze layer and a pattern layer stacked sequentially from the inside to the outside and anti-slip effect glaze layer;

[0039] Such as Figure 2-3 As shown, the surface of the green body 1 is an anti-slip functional glaze layer 2, and the surface of the anti-slip functional glaze layer 2 is provided with a plurality of raised particles 21, and a U-shaped glaze surface 22 is formed between the raised particles 21; the raised particles 21 It has a good anti-slip effect, and the structure of the U-shaped glazed surface 22 makes it easy to clean out the stains hidden in the raised particles 21 .

[0040] The raw material of the anti-skid glaze layer comprises the following components in parts by mass:

[0041] 41 parts of potassium feldspar, 5 parts of nepheline, ...

Embodiment 2

[0063] An antique brick with anti-slip effect, comprising an antique brick body and an anti-slip functional glaze layer covering the surface of the body, the anti-slip functional glaze layer includes an anti-slip surface glaze layer and a pattern layer stacked sequentially from the inside to the outside and an anti-slip effect glaze layer; the surface of the anti-slip effect glaze layer is provided with a plurality of raised particles;

[0064] The raw material of the anti-skid glaze layer comprises the following components in parts by mass:

[0065] 35 parts of potassium feldspar, 3 parts of nepheline, 8 parts of zirconium silicate, 4 parts of burnt talc, 8 parts of air knife kaolin, 3 parts of zinc oxide, 12 parts of barium carbonate, 4 parts of calcined alumina, 1 part of dolomite, auxiliary materials 1 part; the adjuvant includes sodium tripolyphosphate and methyl cellulose with a mass ratio of 1:1.

[0066] Further, the chemical composition of the anti-skid glaze layer i...

Embodiment 3

[0082] An antique brick with anti-slip effect, comprising an antique brick body and an anti-slip functional glaze layer covering the surface of the body, the anti-slip functional glaze layer includes an anti-slip surface glaze layer and a pattern layer stacked sequentially from the inside to the outside and an anti-slip effect glaze layer; the surface of the anti-slip effect glaze layer is provided with a plurality of raised particles;

[0083] The raw material of the anti-skid glaze layer comprises the following components in parts by mass:

[0084] 45 parts of potassium feldspar, 6 parts of nepheline, 12 parts of zirconium silicate, 8 parts of burnt talc, 12 parts of air knife kaolin, 5 parts of zinc oxide, 17 parts of barium carbonate, 8 parts of calcined alumina, 5 parts of dolomite, auxiliary materials 1.2 parts; the adjuvant includes sodium tripolyphosphate and methyl cellulose with a mass ratio of 1:1.

[0085] Further, the chemical composition of the anti-skid glaze l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com