Environment-friendly ether-containing elastomer and preparation method thereof

An elastomer and environmentally friendly technology, applied in the field of ether-containing polymers and their preparation, can solve the problems of limited molecular structure adjustable space, low heat resistance, poor tolerance, etc., and achieve melt processing stability and Excellent anti-aging performance, high end-capping efficiency, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

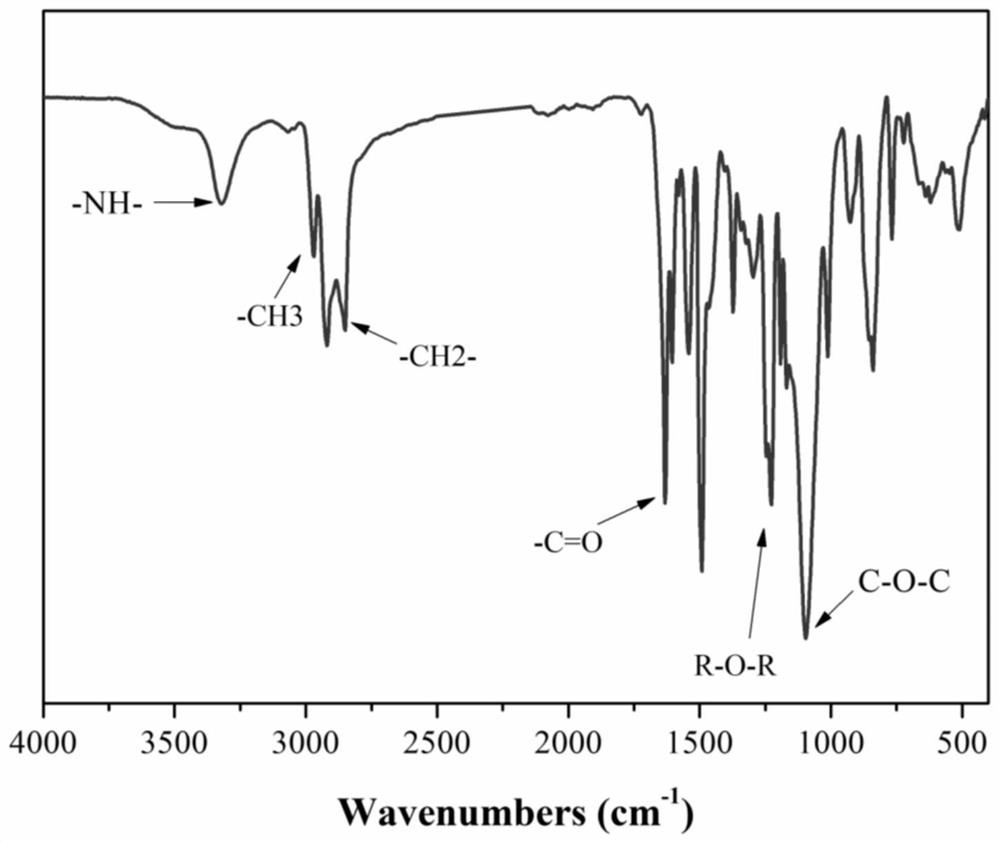

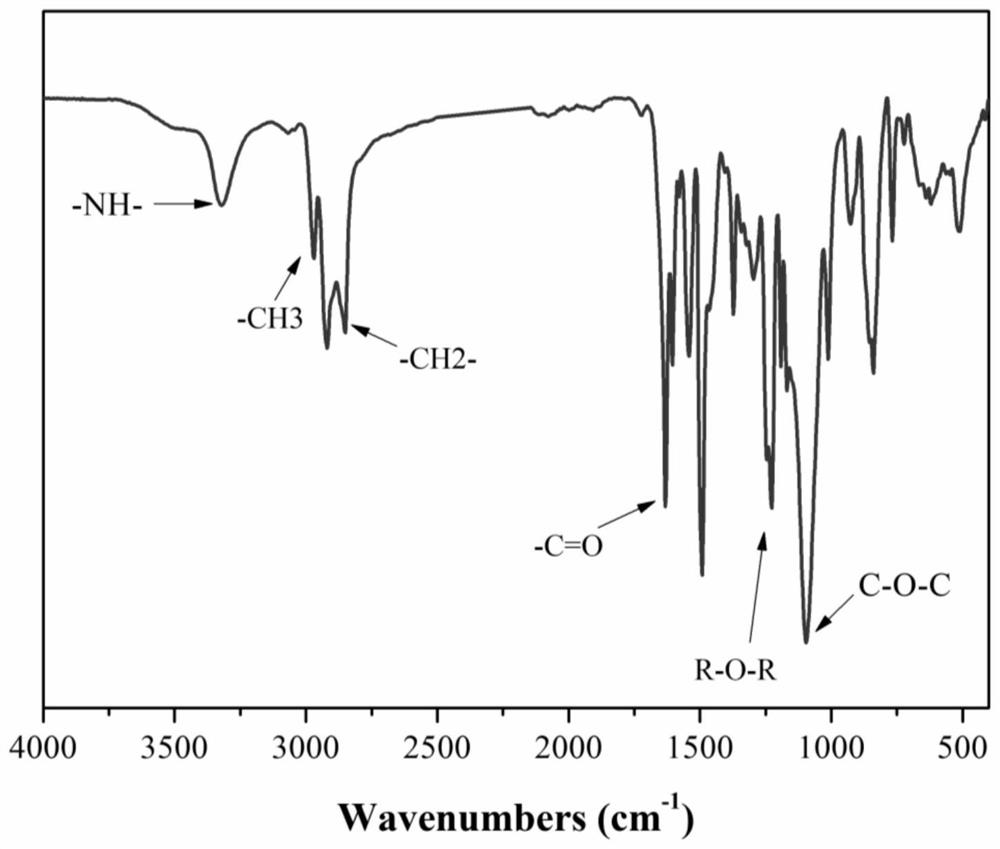

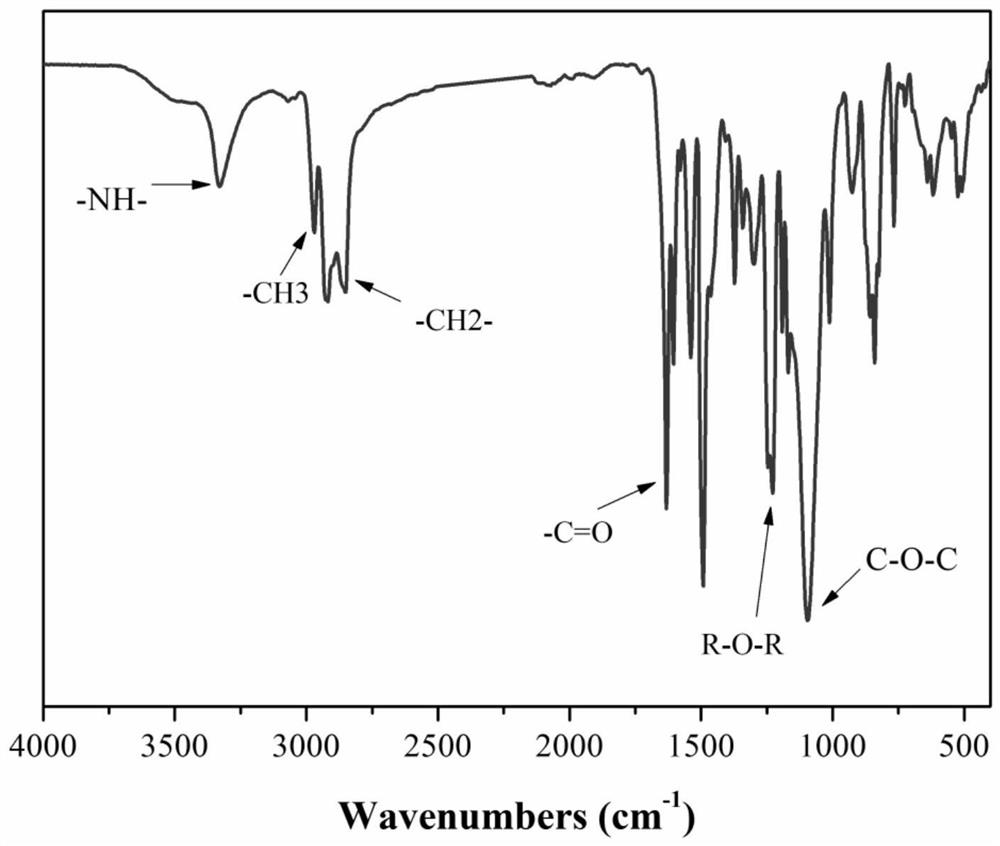

Image

Examples

Embodiment 1

[0051] Embodiment 1 (hydroquinone-C12-80%-2000-20%)

[0052] (1) 36g CH 3 COONa, 138g sodium carbonate, 2000g solvent isoquinoline and 110g hydroquinone were added to the pre-reaction kettle, and under the protection of nitrogen, dehydration reaction was performed at a temperature of 220°C for 1.5h to obtain a dehydrated pre-reaction solution at a constant temperature; (4-fluorobenzoyl)-1,12-dodecanediamine, bis(4-fluorobenzoyl)-isopropyl ether diamine with a degree of polymerization of 33 449g and 1000g solvent isoquinoline are added to the pre-mixer In the process, after the dihalogenated monomer is dissolved, the pre-reaction solution and the monomer solution in the pre-mixer are sent into the serial microchannel reactor (module number: 30 groups) by a high-pressure metering pump to control the pre-reaction The feed molar ratio of the solution and the monomer solution in the pre-mixer is 1:1.001 (oxygenated monomer: dihalogenated monomer), the feed rate is 150g / min, the po...

Embodiment 2

[0056] Embodiment 2 (hydroquinone-C6-75%-2000-25%)

[0057] (1) Add 30g of zinc benzoate, 140g of potassium carbonate, 1500g of solvent N-methylpyrrolidone and 110g of hydroquinone into the pre-reaction kettle, and under the protection of nitrogen, dehydrate at a temperature of 200°C for 1.5h to obtain dehydrated Pre-reaction solution, constant temperature; 270g of bis(4-fluorobenzoyl)-1,6-hexanediamine, bis(4-fluorobenzoyl)-562g of isopropyl ether diamine with a degree of polymerization of 33 and 1000g of solvent N-Methylpyrrolidone joins in the pre-mixer, and after the dihalogenated monomer is dissolved, the monomer solution in the pre-reaction solution and the pre-mixer is sent into the serial microchannel reactor ( Number of modules: 60 groups), the feed molar ratio of the monomer solution in the control pre-reaction solution and the pre-mixer is 1:1.001 (oxygen-containing monomer: dihalogenated monomer), the feed rate is 150g / min, Polymerize for about 1600s at a temperat...

Embodiment 3

[0061] Embodiment 3 (hydroquinone-C10-80%-400-20%)

[0062] (1) Add 20g of sodium succinate, 2g of potassium hydroxide, 800g of solvent sulfolane and 142g of hydroquinone to the pre-reaction kettle, and under the protection of nitrogen, dehydrate at a temperature of 220°C for 2.5h to obtain the dehydrated pre-reaction Reaction solution, constant temperature; 332.8g of bis(4-fluorobenzoyl)-1,10-decanediamine, bis(4-fluorobenzoyl)-129g of isopropyl ether diamine with a degree of polymerization of 6 and 1000g of solvent N sulfolane joins in the premixer, and after the dihalogenated monomer dissolves, the monomer solution in the prereaction solution and the premixer is sent into the serial microchannel reactor (number of modules: 50 groups), the feeding molar ratio of the monomer solution in the control pre-reaction solution and the pre-mixer is 1:1.001 (sulfur-containing monomer: dihalogenated monomer), the feeding speed is 80g / min, and the polymerization is about 1500s , the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com