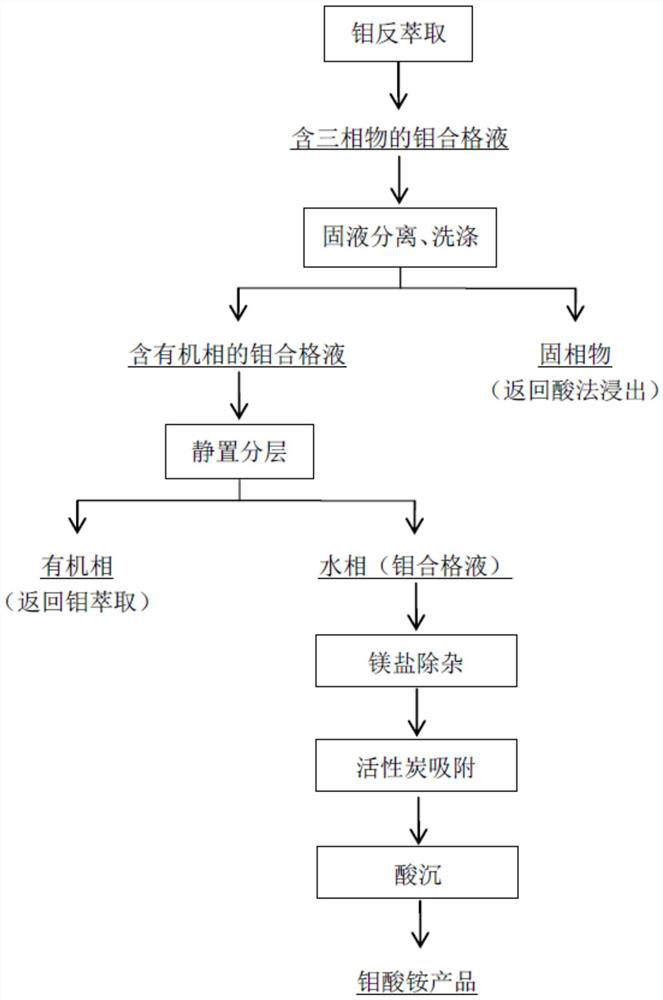

Separation and recovery method for molybdenum back-extraction three-phase substances in uranium-molybdenum ore hydrometallurgy

A technology of hydrometallurgy and recovery method, which is applied in the direction of improving process efficiency, etc., and can solve the problems of organic phase loss, high consumption of purifying agent, loss of uranium and molybdenum metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, put the qualified molybdenum stripping solution discharged from the aqueous phase outlet of the molybdenum stripping mixed clarifier into the buffer tank to obtain the qualified molybdenum solution containing three phases, and the content of the three phases (three phases) in the qualified solution for molybdenum stripping The ratio of dry weight of slag to molybdenum qualified liquid) is 5g / L, and the temperature is 25°C.

[0032] Step 2. Connect the experimental device Buchner funnel, suction filter bottle, and vacuum suction filter for preparation. Spread qualitative filter paper on the Buchner funnel and wet it with clean water, then start the suction filter, and take 2L back extraction to obtain qualified molybdenum with three phases. Add liquid into the Buchner funnel for negative pressure suction filtration at -650mmHg. The suction filtration time is about 40min. There is no obvious accumulation of liquid on the surface of the three-phase filter cake. The...

Embodiment 2

[0038] Step 1, put the qualified molybdenum stripping solution discharged from the aqueous phase outlet of the molybdenum stripping mixing clarifier into a beaker and other containers to obtain the qualified molybdenum solution containing three phases, and the content of the three phases (three phases) in the molybdenum stripping qualified solution The ratio of dry weight of slag to molybdenum qualified liquid) is 8g / L, and the temperature is 30°C;

[0039] Step 2. Connect the experimental device Buchner funnel, suction filter bottle, and vacuum suction filter to prepare. Spread qualitative filter paper on the Buchner funnel and wet it with clean water, then start the suction filter, and take 4L back extraction to obtain qualified molybdenum with three phases. The liquid is added into the Buchner funnel for -650mmHg negative pressure suction filtration. The suction filtration time is about 2 hours. There is no obvious liquid accumulation on the surface of the three-phase filter...

Embodiment 3

[0045] Step 1, put the qualified molybdenum stripping solution discharged from the aqueous phase outlet of the molybdenum stripping mixed clarifier into the buffer tank to obtain the qualified molybdenum solution containing three phases, and the content of the three phases (three phases) in the qualified solution for molybdenum stripping The dry weight of slag and the volume ratio of molybdenum qualified liquid) is 15g / L, and the temperature is 35°C; the increase of temperature is beneficial to the solid-liquid separation and filtration speed, but the ammonia gas in the molybdenum qualified liquid volatilizes strongly when the temperature is too high, which affects the ambient air quality, which is not conducive to occupational health, and increases the difficulty of ventilation. The qualified molybdenum stripping liquid containing three-phase substances in the buffer tank can be directly separated from the solid and liquid without temperature adjustment.

[0046] Step 2. Pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com