Composite-morphology nano cellulose transparent film based on waste paper and preparation method of composite-morphology nano cellulose transparent film

A technology of nano-cellulose and transparent film, applied in pulp beating method, secondary cellulose fiber, fiber raw material treatment, etc., can solve the problems of single recycling method, low added value of products, waste of resources, etc., and achieve good thermal stability Performance and oxygen barrier performance, creating economic and environmental benefits, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

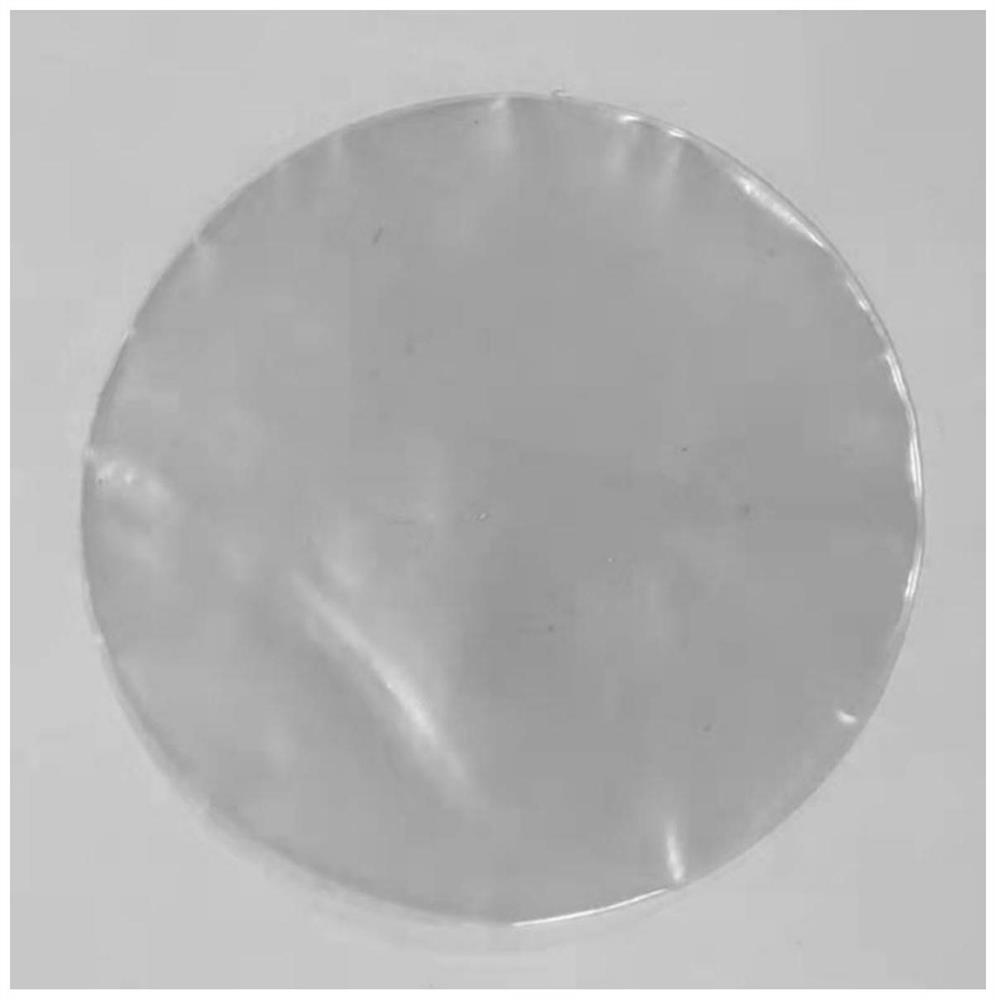

Image

Examples

Embodiment 1

[0079] The preparation method of the composite shape nano-cellulose transparent film based on waste paper comprises the following steps:

[0080] Step 1, take the following components by weight: 1.59% waste inkless A4 paper, 32.27% deionized water, 0% deinking agent, 66.14% mass fraction of 98% concentrated sulfuric acid, the weight percentage of the above components sum to 100%;

[0081] Step 2, preparing waste paper fiber, the specific operation steps are as follows:

[0082] Step 2.1, crush the waste paper into pieces of 20mm×10mm, add deionized water to soak for 40min, and obtain the waste paper liquid;

[0083] Step 2.2, pour the waste paper liquid obtained in step 2.1 into a beater for beating for 40 minutes, pour it into a 325-purpose standard inspection sieve after beating, rinse with water several times, remove foam, and drain the water to obtain waste paper pulp;

[0084] Step 2.3, put the waste paper pulp in a petri dish, put it into an electric blast drying oven,...

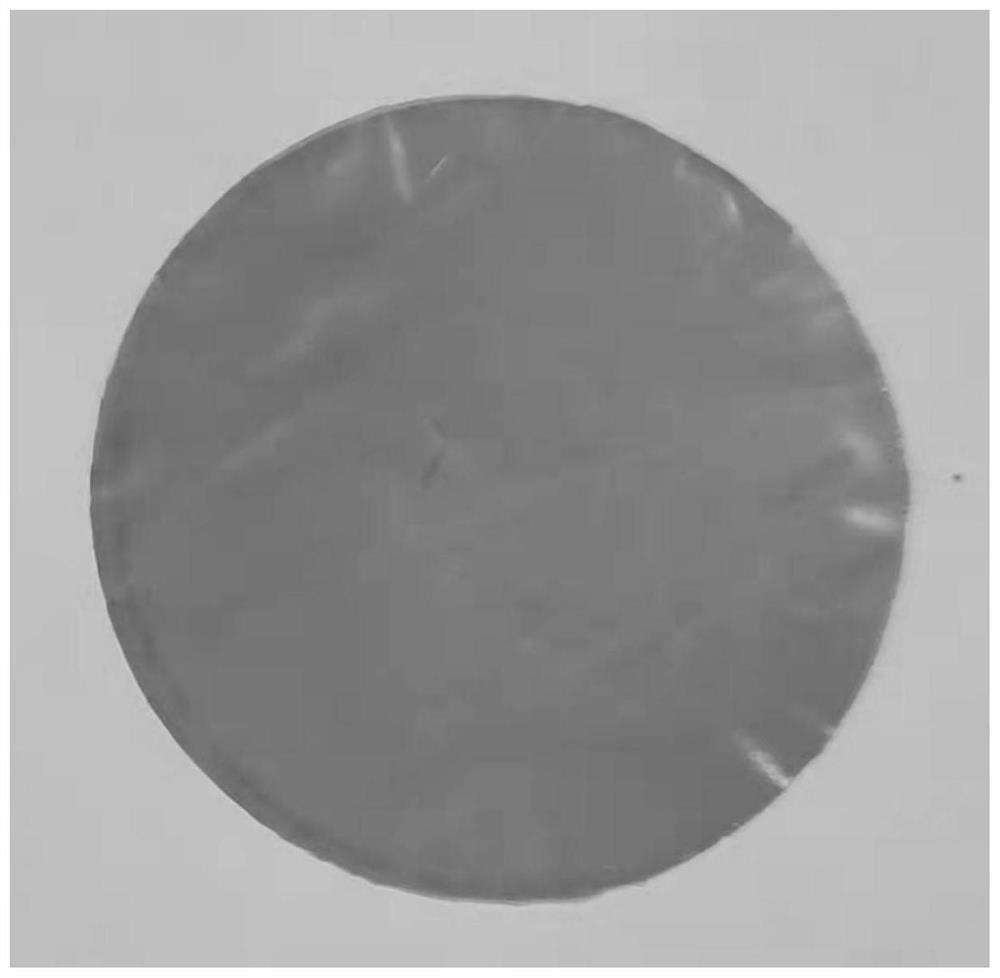

Embodiment 2

[0098] A kind of preparation method based on the composite appearance nano-cellulose transparent film of waste paper, comprises the following steps:

[0099] Step 1, take the following components by weight: 1.63% waste A4 paper with ink, 32.66% deionized water, 0.38% deinking agent, 65.33% concentrated sulfuric acid with a mass fraction of 98%, the weight percentage of the above components The sum is 100%; wherein the mass ratio of each component in the deinking agent is: H 2 o 2 :NaOH:Na 2 SiO 3 : SDBS: OP-10 = 2.8:0.4:1.3:0.35:0.45.

[0100] Step 2, preparing waste paper fiber, the specific operation steps are as follows:

[0101]Step 2.1, crush waste paper into 18mm×8mm fragments, add deionized water and deinking agent to soak for 30min, and obtain waste paper liquid;

[0102] Step 2.2, pour the waste paper liquid obtained in step 2.1 into a beater for beating for 30 minutes, pour it into a 325-purpose standard inspection sieve after beating, rinse with water several t...

Embodiment 3

[0117] A kind of preparation method based on the composite appearance nano-cellulose transparent film of waste paper, comprises the following steps:

[0118] Step 1, take the following components by weight respectively: 1.79% waste A4 paper with ink, 35.41% deionized water, 0% deinking agent, 62.80% mass fraction is 98% concentrated sulfuric acid, the weight percentage of the above components sum to 100%;

[0119] Step 2, preparing waste paper fiber, the specific operation steps are as follows:

[0120] Step 2.1, crush the waste paper into 15mm×4mm pieces, add deionized water to soak for 20min, and obtain the waste paper liquid;

[0121] Step 2.2, pour the waste paper liquid obtained in step 2.1 into a beater for beating for 20 minutes, pour it into a 325-purpose standard inspection sieve after beating, rinse with water several times, remove foam, and drain the water to obtain waste paper pulp;

[0122] Step 2.3, put the waste paper pulp in a petri dish, put it into an elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com